4211-189 08-09-11

A220FP Fragrance Injector Pump

Installation and Operating Instructions page 6

BasicOperation(continued)

• Pressing the switch while the injector system is running will turn the system off again.

• The essential oil will only be pumped into the steam outlet while steam is being sent to the room. This helps carry the

essence into the room and reduces the risk of oil building up in the steam line, unused.

• Repeatedly turning the injector system on and off will not affect the amount of essence released to the room.

We recommend starting the Fragrance Injector after starting your steam bath. Start at about 10 minutes after the steamer

is turned on then adjust this period with later baths until you have determined how long gives you the right amount of

essence in your room. Starting the injector too early can cause the room to have too much essence.

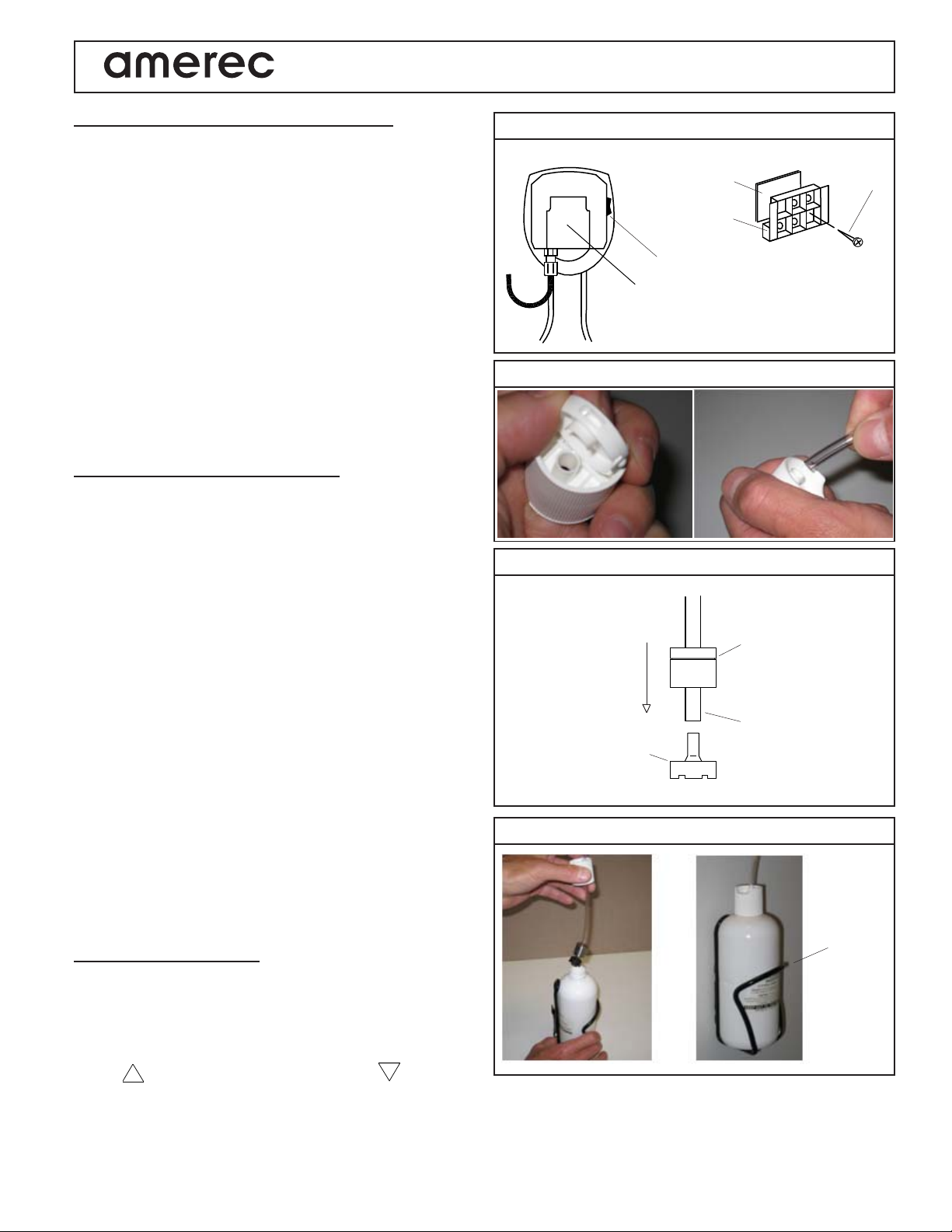

Speed (Flow Rate) Adjustment (Diagram 8)

You can adjust how much essence oil is added to your bath by changing the pump's speed. The speed is set at the

factory at the medium level and the injector should be tested for user preference at this speed first.

Toadjustthespeedremovetheclearcover on the front of the pump. The speed adjustment may be found to the right of

the pump's LED. Make only small adjustments and retest after each adjustment until the preferred speed is determined.

• To reduce speed, use a small screwdriver to turn the speed adjustment screw to the left (counterclockwise).

• To increase speed, use a small screwdriver to turn the speed adjustment screw to the right (clockwise).

Whenfinished,replacetheclear cover. Lightly tighten the cover's mounting screws - Do not over tighten!Thecovermay

be damaged if its screws are tightened too much!

Trouble Shooting

• If there is no essence being supplied,

Make sure the pump is operating correctly.

Make sure the essence bottle is full and the filter is clean and in the essence oil.

Make sure the pump tubing is filled with essence oil.

Check the pump's squeeze tube for damage or leaks.

• If the essence supply into the steam line becomes clogged, tighten the piercing arm (see Diagram 2) all the way down

through the 1/2 inch copper steam line and then all the way back out.

• If the essence scent is too strong and the pump is set at it's lowest setting, the essence can be diluted with 100%

safflower oil available at most grocery stores.

• If the On/Off switch's LED does not light, press the pump's switch to its Mom position: the pump should turn and its

LED should light. If the pump is working, there may be a fault with the ON/Off control or its cable. Check its connec-

tions and call Steam Service if the fault is not found.

• If the pump does not turn and the LEDs light, the pump may be faulty; call Steam Service.

• If the pump and LEDs do not work, make sure the wiring connections are correct and that the power adapter is

connected to a working 120VAC outlet. A voltmeter may be used to check the transformer output: it should be 24VAC.

Fortroubleshootingassistance,contactTechnicalSupportat1-800-363-0251

Pump Squeeze Tube Replacement

Toremovethesqueezetube:

•Unplugthepoweradapter.

•Removethetransparentfrontcover.

• Turn the roller assembly so that the rollers are situated vertically, slide the connection on the left toward you pulling the

tube out of its seat and manually rotate the roller assembly clockwise until it is possible to extract the right hand side

connection from its seat.

To install the new tube:

• Turn the roller assembly so that the rollers are lined up horizontally;

• Insert the connection in its seat on the left of the pump with the curved side towards the rear of the pump and

push the tube into its seat while manually rotating the roller housing clockwise until it is possible to

insert the right hand side connection into its seat.

• Remount the front cover. Tighten the cover's screw until snug. Do not over tighten! The cover may be damaged if its

screws are tightened too much!