10

1.

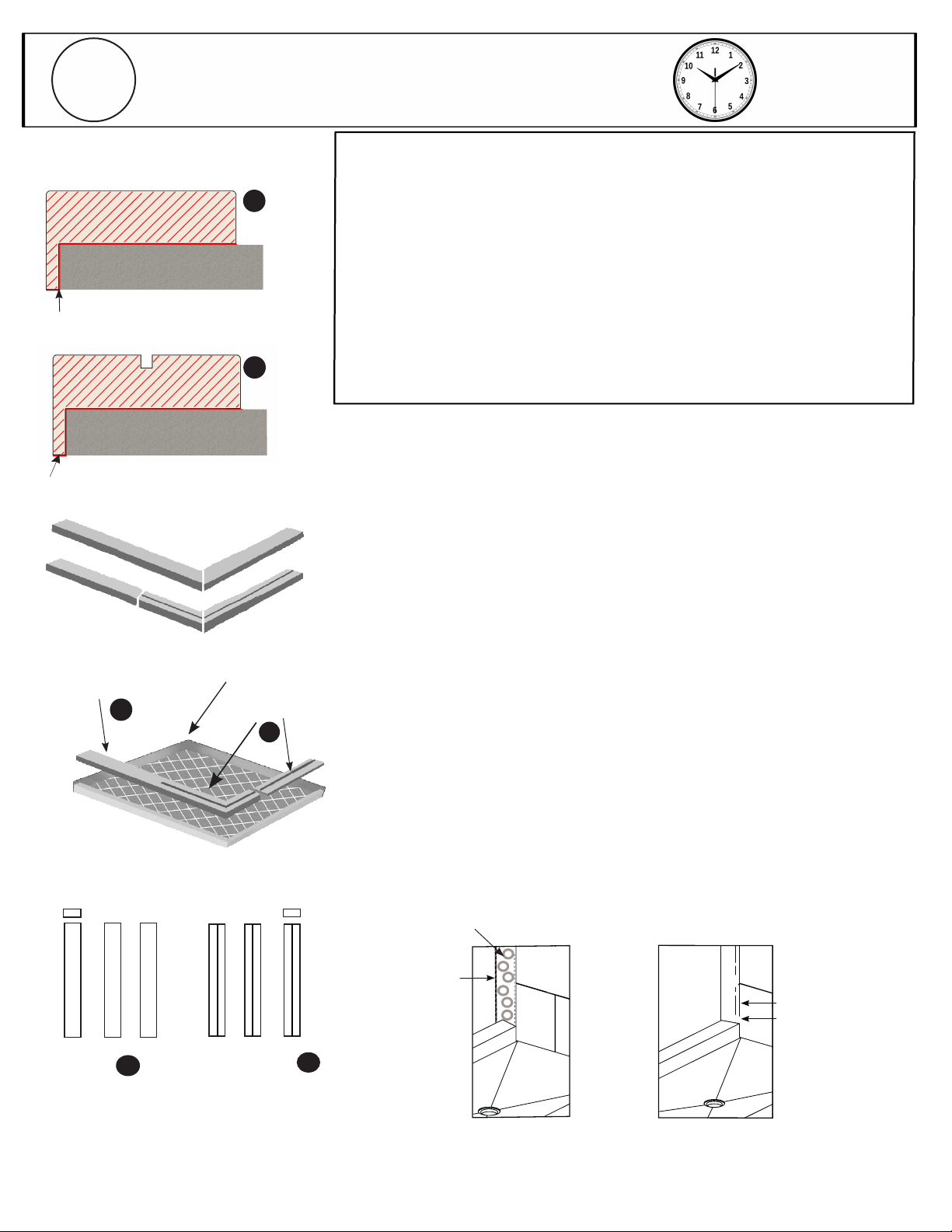

Gently insert the side glass panel into the channels. With someone helping you,

place the door return glass panel into the door rail. Install the corner support

bracket. (dia. 20) You will be adjusting the fixed glass panel so it's level with the

door and has an even ¼" gap between the door and the glass panel. Use rubber

setting block to adjust height and level if necessary.

2.

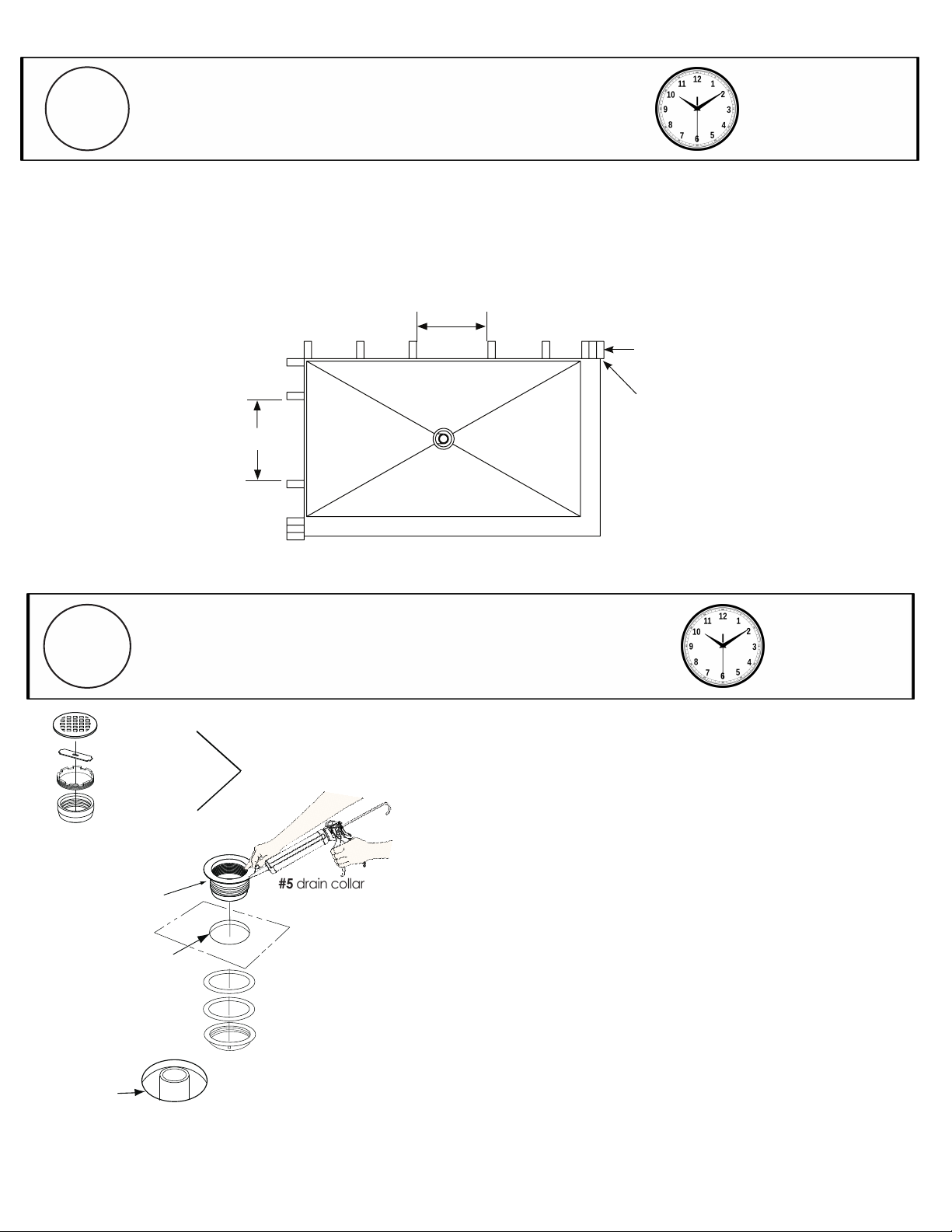

Next, to determine the position of the bottom hinge pin hole, place the top hinge

pin bracket upside down on bottom pan threshold as a template. (dia. 21) Align

bracket hole to center of side glass panel. Mark the hole and remove the bracket.

Carefully drill ¼" dia hole for hinge pin approximately 1¼" deep into the pan

threshold.

3.

Pick up the door you have installed the hinges and handle onto, and gently place

the bottom hinge pin into the ¼" hole you have drilled into the pan threshold.

(making sure you have the Teflon slide washer on the pin)

D - Install Fixed Glass Panel & Glass Door

1.

2.

3.

With someone helping to hold the shower door, place the top hinge mounting

bracket (dia. 22) over the top hinge pin (making sure you have the Teflon slide washer

on the pin). Check to make sure door is plumb and level, then mark with a pencil

through the 3 holes on top hinge mounting bracket.

Move door and top hinge mount to one side and pre-drill the holes into the studs.

The drilled holes should be large enough so the screws don’t bind in the stone.

Insert and tighten screws.

Next dry-fit the side panel into the correct alignment with the door, remove the

glass and apply a ¼" bead of 100% silicone into the channels. Re-insert the fixed

glass panel and check alignment again. Allow the silicone to dry. You can silicone

any gaps between the stone and glass to ensure water tightness.

diagram 21

diagram 20

gasket

set screws

gasket

SB

C - Dry-fit Fixed Glass Panel & Glass Door

side wall

casing top hinge

pin bracket

¼” pin hole

pan threshold

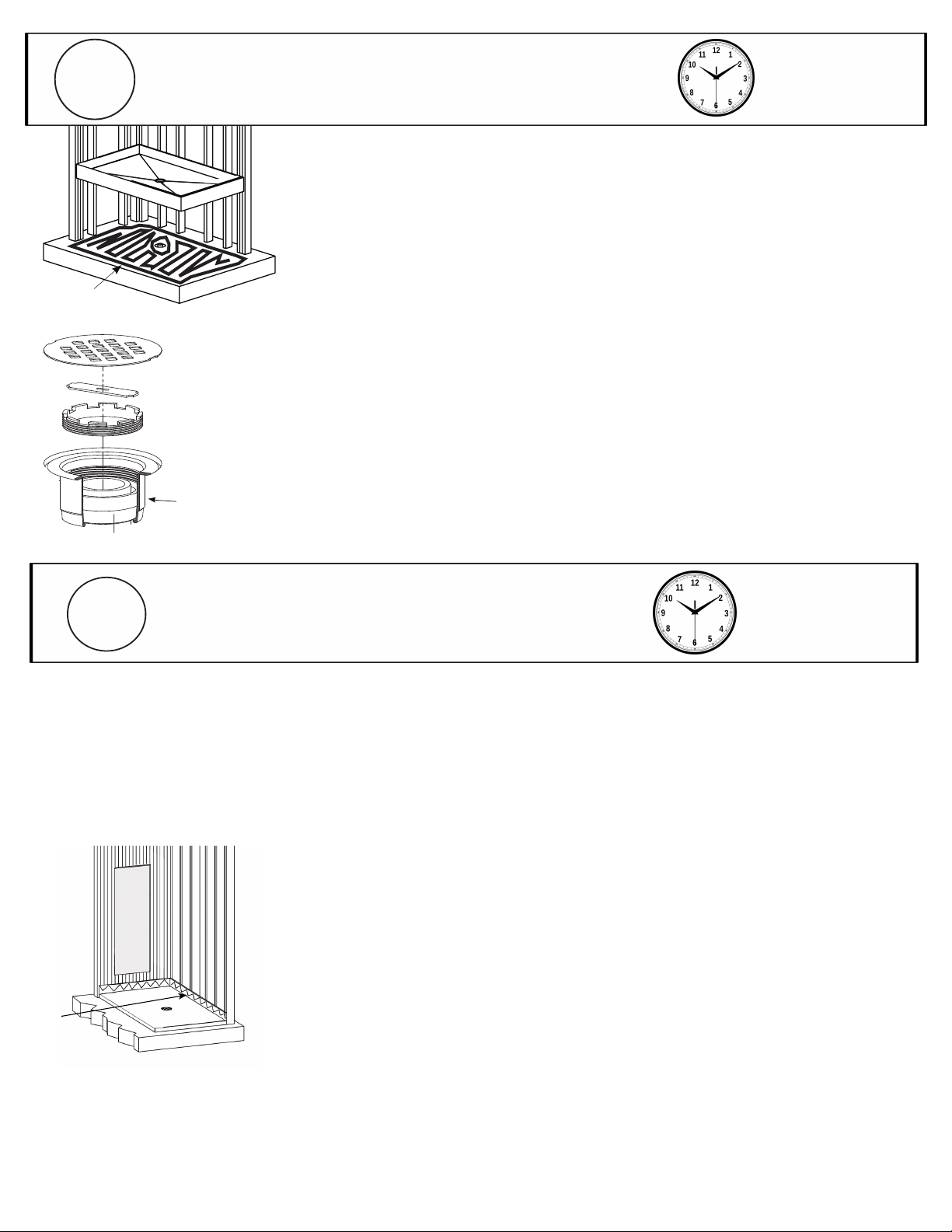

diagram 23

Glass

Door

to inside

of shower

*To keep door

closed adjust height

of door sweep to

provide proper

tension and seal

*

Shower Threshold

diagram 24

glass

panel

strike

side

door

hinge

side

inside shower

outside shower

GD

GP

GS GH

h-seal

L-seal

hinge

pin

side

plate

diagram 22

side

plate

hinge

pin

inside

shower

outside

shower

T eflon slide

washer

teflon slide

washer

hinge wall

bracket

screw

(3 places) HB

GH

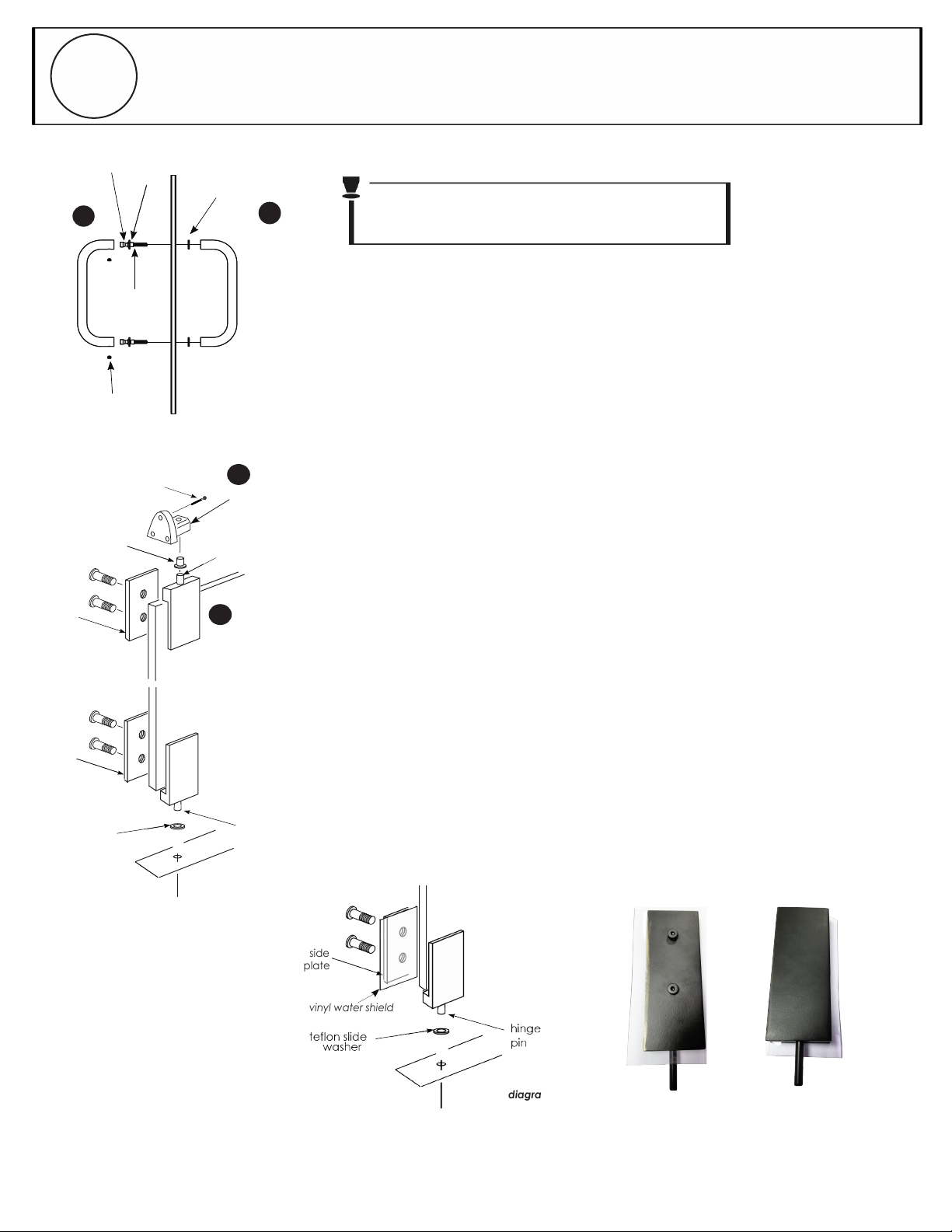

E - Install Door Sweep & Seals

Locate the clear door sweep and attach it to the bottom of the glass door. The

reflective shield should face into the shower. (dia 23) The door sweep is what keeps the

door closed. Adjust the door seal until the required tension is achieved. The door

sweep has been cut to fit over the hinge. Cut off the excess length opposite of hinge

side.

We have provided door seals for water sensitive areas such as wood floors. If glass

panels and door are installed correctly with the proper spacing, outside water spillage

will be minimal and the side seals won’t be necessary.

If you would like to use these side seals, follow the steps below:

1.

2.

3.

4.

5.

6.

7.

The L-shaped seal goes along the hinge side of the door on the threshold trim

pieces. (dia. 24)

Place the seal along the edge of the glass and cut the seal to the proper

length.

Remove the backer from the seal exposing the double-sided tape, only

remove a small amount at a time.

Starting from the top, align the seal along the edge of the door and stick the

seal to the threshold.

Work your way down the door. Do small sections at a time, slowly peeling the

backer off the seal.

Locate the plastic h-shaped seal. It goes on the fixed glass, next to the handle

edge. (dia. 24) Measure and cut the seal to length.

Starting from the top, push the seal onto the glass panel, slowly working your

way down.