5SHOWER PAN INSTALLATION TIME REQUIRED

1 - 2 HRS

10

BEFORE YOU START - Make sure floor is clean and level. Check to make sure existing plumbing will be accessible after

pan is installed. Check your local building codes before installation.

To ensure that no damage has occurred to your shower pan during shipping, it is important to check your pan for

damage prior to installation in your home. Damage caused by shipping may result in a hairline fracture that could leak

over time.

Move your shower pan to a location that will not be damaged by water run-off. A driveway or patio is suitable for

testing your new shower pan.

Set the pan on blocks high enough to see the underside of the pan. Plug the drain and fill the shower pan with water.

Check for leaks and proper slope of the top pan surface. If there is no damage and no leaks then the shower pan is

ready to be installed.

Be careful while moving the shower pan. Bumping or dropping the shower pan can cause hairline fractures that can

leak over time.

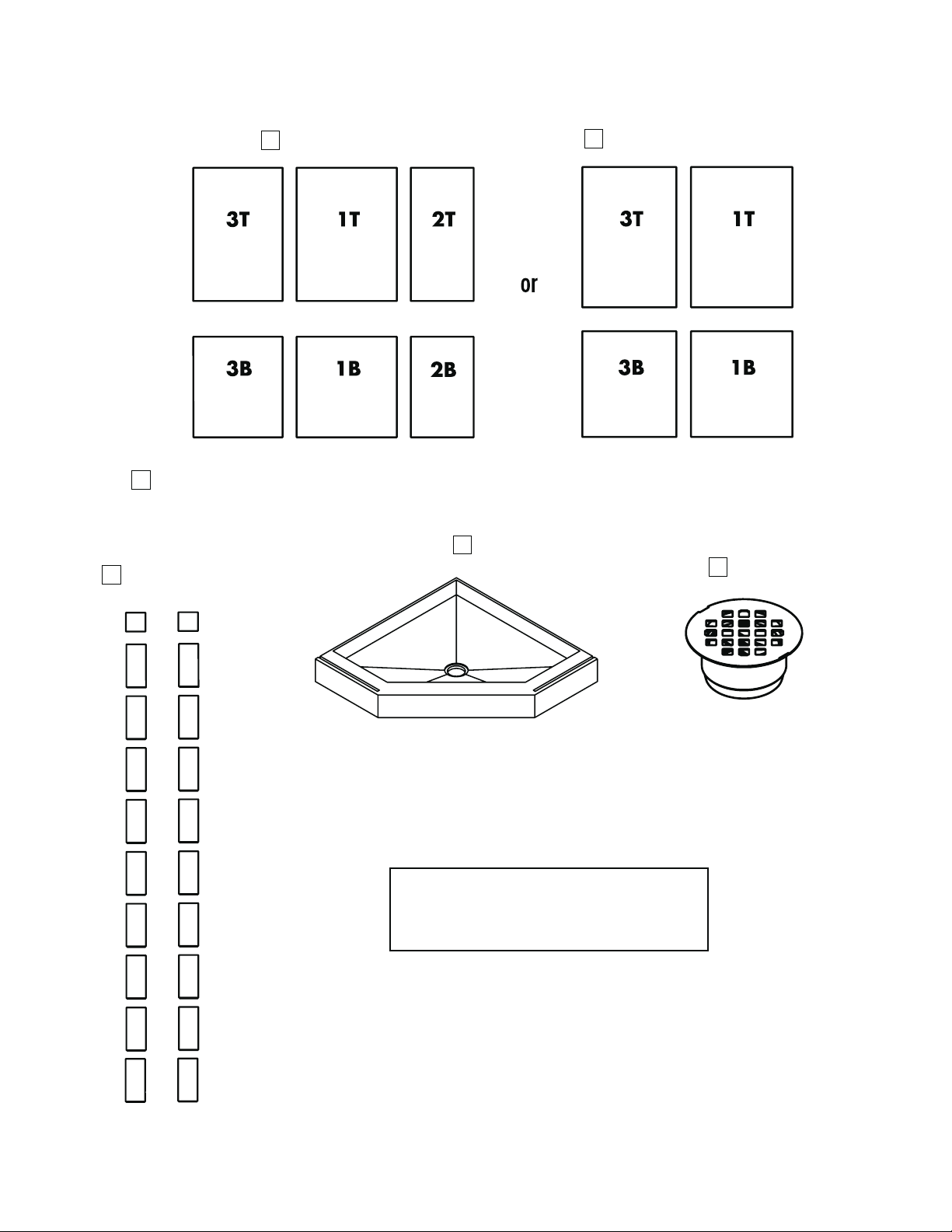

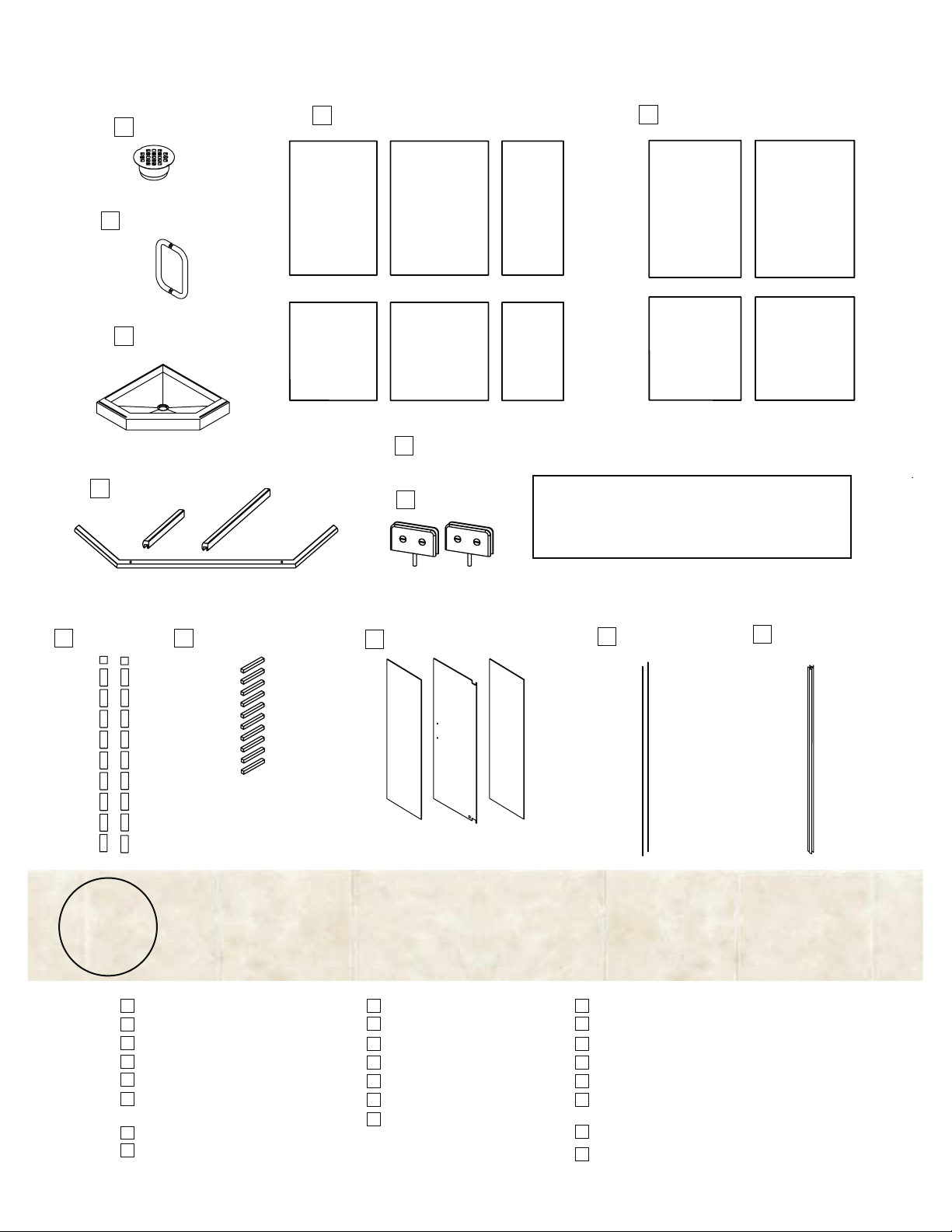

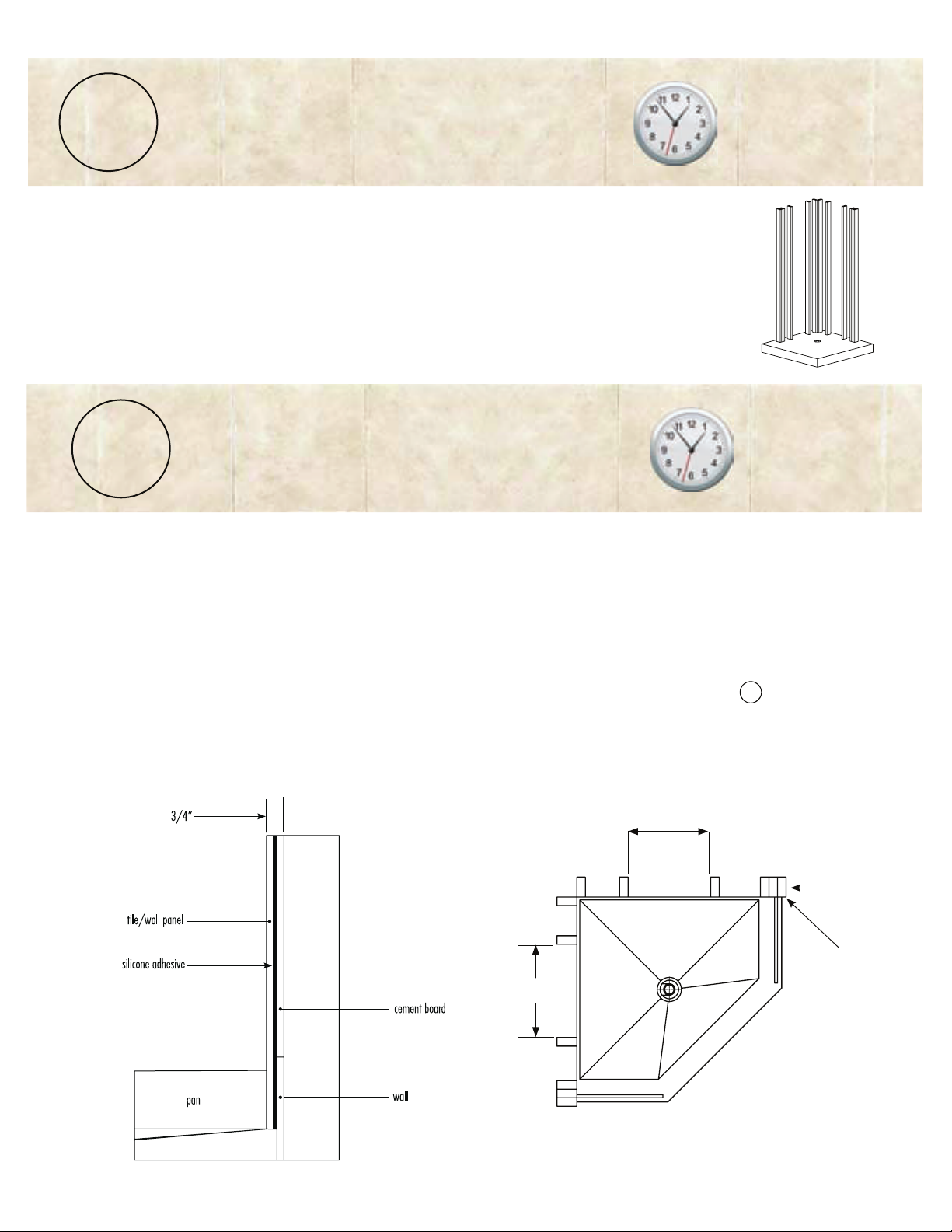

1. The shower pan comes with a 2” drain assembly kit (fig. 3).

2. Measure from the wall studs to make sure your 2” ABS drain is in the correct location. Dry test by resting the

shower pan over the 2” drain pipe. You may want to place 2 x 4’s on the floor to help support the pan from

resting on the drain.

3. Make sure the 2” ABS drain pipe is in the center of the shower pan opening and at the right height (1” above

floor). Dry fit the drain collar. Compare the thickness of the pan with the drain collar, provide proper clearance

for drain to set flush on pan.

4. Place wood shims, if necessary, along the 2 x 4’s to square out the pan. This may cause problems installing

the system if the walls are not straight and if the shower pan is not set against wall studs.

5. Remove the shower pan and any wood shims after checking and verifying the drain hole is in its

correct location.

.

Use a level to make sure the 2 x 4’s for the walls are vertically straight.

Make sure that the shower pan sets flush against the 2 x 4’s on each side.

6. Set the shower pan in a safe location. (fig. 3).

7. Apply a generous bead of silicone around the shower pan drain opening and drain collar, insert the drain collar

into the drain hole.

8. Apply a generous bead of silicone around the drain collar from the underside of the pan.

9. Install the rubber gasket over the drain collar, to the underside of the pan, next install the Teflon slide ring.

10. Screw on drain lock nut and hand tighten. Turn drain nut approximately 1/4 turn with wrench to ensure

water-tight fit. Check for good seal. DO NOT OVERTIGHTEN.

11. Wipe off excess silicone and allow silicone to dry. Follow the manufacturer’s directions for application and

drying time.

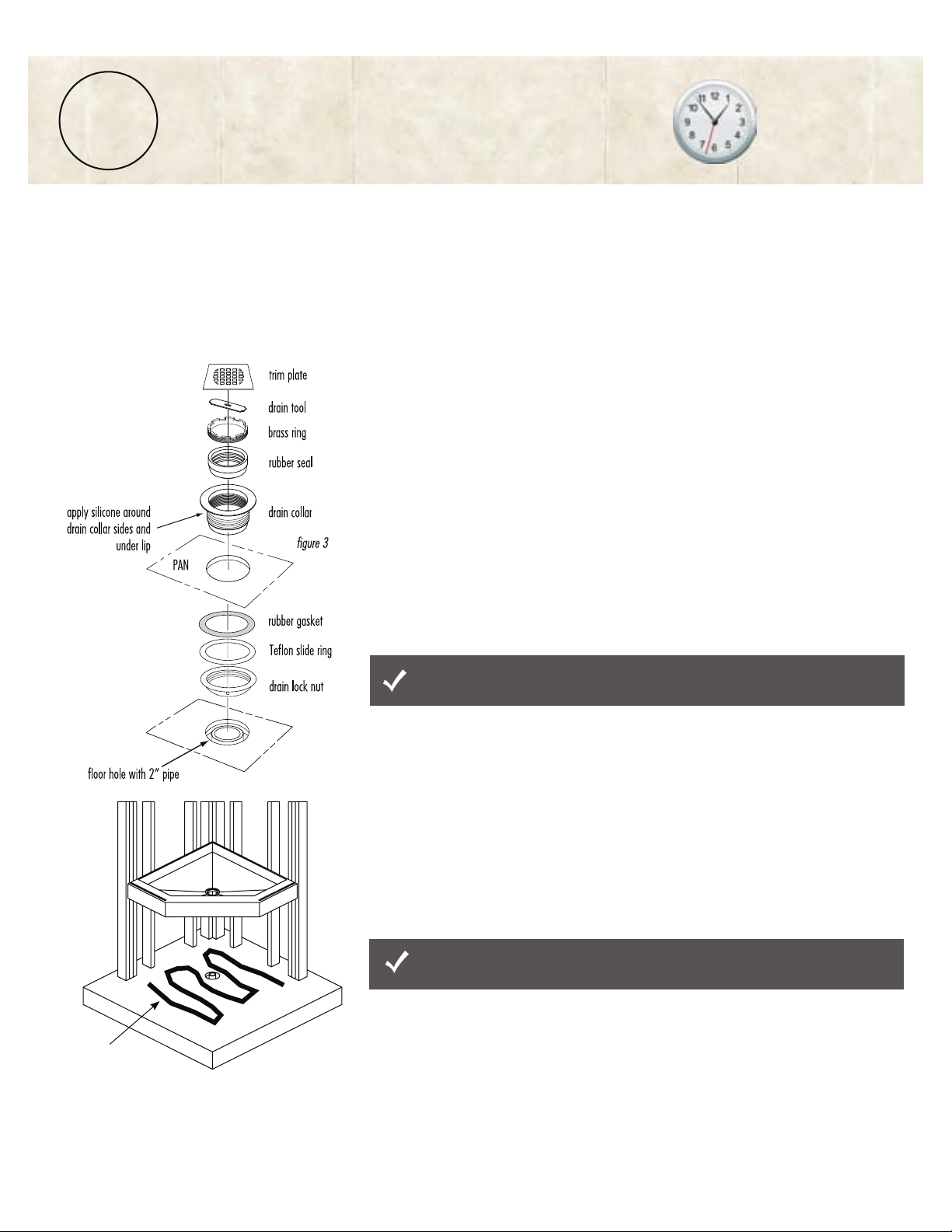

12. Apply silicone to the floor area where the pan is to be installed (fig. 4).

See Silicone Recommendations

High quality Thinset may be used on uneven floors.

13. Carefully lift the shower pan and set into place. Make sure the ABS pipe is still centered.

14. Push and secure the rubber seal into the 2” ABS pipe.

15. Thread on the brass pressure ring around the drain with the provided tool. Remove the tool after brass ring

is installed.

16. Test and snap the decorative diamond pattern trim plate into position. (Remove decorative trim plate and

store in secure area until installation is complete, drain will be grouted when shower is grouted.

17. After installing pan, cover with cardboard to protect pan from scuffs.

figure 4

apply silicone