FAILURE TO PROVIDE AN EXPANSION TANK ON THE COLD WATER LINE ON A CLOSED SYSTEM WILL VOID THE WARRANTY

ON THE WATER HEATER.

FOR YOUR SAFETY

Do not use or store gasoline or any other flammable vapors, liquids, or materials in vicinity of this or any other appliance.

FOR YOUR SAFETY - WHAT TO DO IF YOU SMELL GAS

. Do not try to light any appliance.

. Do not touch any electrical switch; do not use any phone in your building.

. Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier´s instructions.

. If you cannot reach your gas supplier, call the fire department.

Improper installation, adjustment, alteration, service, or maintenance can cause injury or property damage. Refer to this manual.

For assistance or additional information consult a qualified installer, service agency, or the gas supplier.

THIS WATER HEATER MUST BE PROPERLY AND REGULARLY MAINTAINED.

FAILURE TO DO SO WILL VOID THE WARRANTY.

Please complete the following information at the time of installation. This should be retained and presented along with the warranty in case a claim

is necessary.

MODEL NUMBER: TYPE:

SERIAL NUMBER:

INSTALLATION ADDRESS:

THIS WATER HEATER HAS BEEN INSTALLED IN ACCORDANCE WITH THESE INSTALLATION

INSTRUCTIONS AND LOCAL CODE REQUIREMENTS ON

INSTALLER:

DATE

WARNING

1

CONSUMER RESPONSIBILITIES

WARRANTY LIMITATIONS

THE MANUFACTURER OF THIS WATER HEATER WILL NOT BE RESPONSIBLE FOR TANK FAILURES OR WATER HEATER FAILURES RESULTING FROM ANY OF

THE FOLLOWING CONDITIONS AND MAY AT IT’S DISCRETIONS VOID THE WATER HEATER WARRANTY WHEN THESE CONDITIONS RESULT IN

PREMATURE FAILURES OF THE TANK OR COMPONENTS

1. INSTALLATIONS NOT COMPLYING WITH ALL LOCAL CODES.

2. FAILURES DUE TO UNDERSIZING OF THE WATER HEATER AND SUBSEQUENT EXCESSIVE BURNER FIRING.

3. BAD WATER CONDITIONS SUCH AS WELL WATER WITH EXCESSIVE MINERAL DEPOSITS. IT IS THE RESPONSABILITY OF THE INSTALLER TO TAKE WHAT EVER STEPS

ARE REQUIRED INCLUDING THE INSTALLATION OF WATER HEATER SOFTENERS, TO PREVENT EXCESSIVE LIME BUILD UP AND SUBSEQUENT METAL FATIGUE DUE TO

OVER HEATING OF THE TANK BOTTOM AND TO USE THE HAND HOLE CLEANOUT PROVIDED IN THIS WATER HEATER TO KEEP LIME DEPOSITS IN THE TANK BOTTOM

EXCEEDING FROM 2” HEIGHT.

4. INSTALLATION OF MULTIPLE WATER HEATERS IN SEQUENCE RATHER THAN PARALLEL RESULTING IN EXCESS FIRING AND/OR EXCESSIVE CONDENSATIONS ON

FIRST HEATER IN SERIES OR OUT OF BALANCE PILOT OUTAGES AND PREMATURE FAILURE OF BURNER COMPONENT PARTS WILL OCCUR.

5. FAILURE TO PROVIDE ADEQUATE COMBUSTION AIR AND A CONTAMINATED AIR OUTLET OR TO ADEQUATE PROPER VENTING RESULTING IN NEGATIVE AIR

PRESSURE DUE TO IMPROPER LOCATION OR LACK OF COMBUSTION SHOWN ON OWNERS OPERATION MANUAL AND THE INSTALLATION IN COMPLIANCE WITH

UNIFORM PLUMB CODE.

6. FAILURE TO INSTALL HEATERS TO MANUFACTURE AND BUILDING SAFETY STANDARDS WILL CAUSE PREMATURE FAILURE OF COMPONENT PARTS, HAZARDOUS

CONDITIONS AND FAILURE OF THE HEATER OR COMPONENTS CAUSED BY CHEMICALS OR SOLVENTS BEING STORED IN THE INMEDIATE VICINITY OF THE WATER

HEATER.

7. FAILURE TO PROVIDE A PROPERLY SIZED EXPANSION TANK ON THE COLD WATER LINE ON A CLOSED SYSTEM.

8. FAILURE ADEQUATE GAS SUPPLY AND PROPER PRESSURE AS OUTLINED ON OWNERS OPERATION MANUAL INSTALLED IN COMPLIANCE WITH UNIFORM PLUMBING

CODE.

9. FAILURE TO INSTALL TEMPERATURE PRESSURE RELIEF VALVE DRAIN AS PER OWNERS OPERATION MANUAL AND IN COMPLIANCE WITH UNIFORM PLUMBING CODE.

10. FAILURE TO SET UP THE ELECTRICAL INSTALLATION IN COMPLIANCE TO OPERATION MANUAL AND TO NATIONAL ELECTRIC CODE.

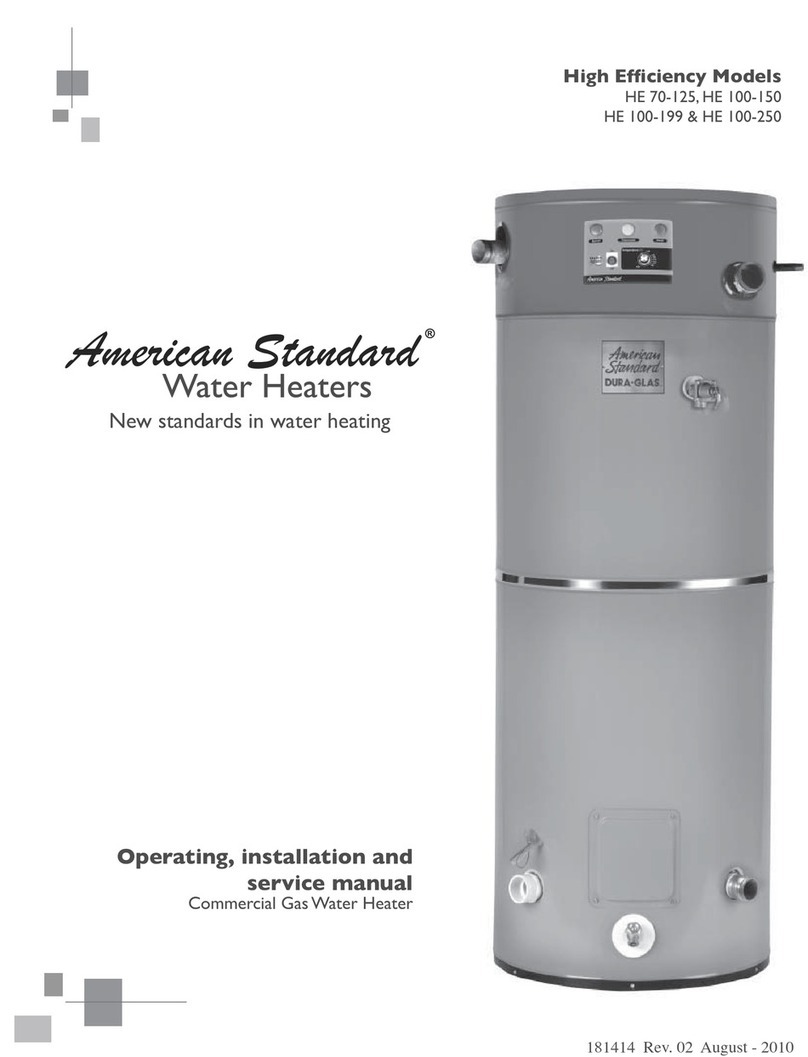

THIS MANUAL HAS BEEN PREPARED TO ACQUAINT YOU WITH THE INSTALLATION, OPERATION AND

MAINTENANCE OF YOUR GAS WATER HEATER AND TO PROVIDE IMPORTANT SAFETY INFORMATION.

WE URGE YOU TO READ ALL INSTRUCTIONS THOROUGHLY BEFORE ATTEMPTING INSTALLATION OR

OPERATION OF YOUR WATER HEATER. KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE.

The manufacturer of this water heater will not be liable for any damages caused by failure to comply with the installation and operating instructions

outlined on the following pages. These instructions are a guide for the correct installation of your water heater. lf you lack the necessary skills

required or have difficulty following the directions, you should not proceed but get help from a qualified person for that part of the installation you

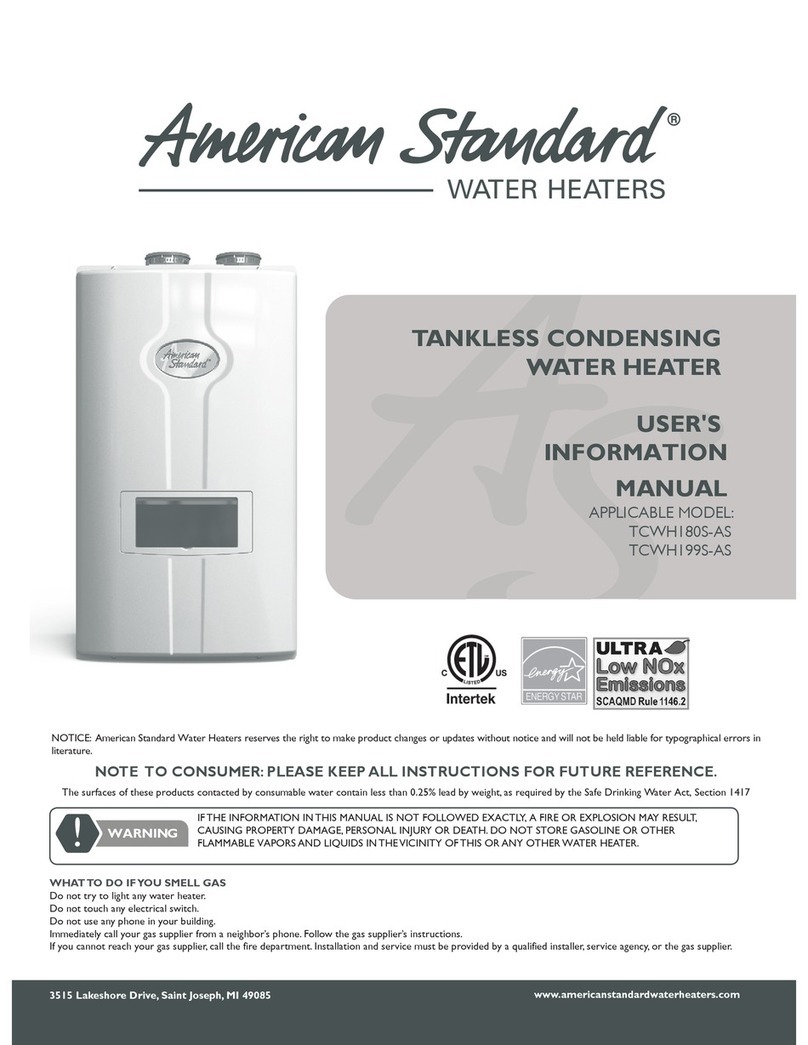

do not understand. Your gas-fired water heater is design-certified by ETL. The installation should conform with the local code or the authority

having jurisdiction, or in the absence of such, the National Gas Code. ANSI Z223.1 NFPA 54. A copy of the Code can be purchased from American

Gas Association Order Processing, 400 N. Capital St. N.W. Washington D.C. 20001 e-mail ordering: www.aga.org Fax ordering: 866-8 I6-9444.

A rating plate identifying your water heater will be found next to the gas control valve (thermostat).

The water utility supply meter may contain a check valve, back flow preventer or water pressure reducing valve. This will create a closed water

system. During the heating cycle of the water heater, the water expands creating a pressure build up in the water system. A temperature and

pressure relief valve must be installed on the water heater (150 PSI maximum pressure setting. See Temperature and Pressure Relief Valve).

If the water supply system contains a check valve, back flow preventer, or water pressure reducing valve you will have closed

water system and the pressure will build up during the water heating cycle. The temperature and pressure relief valve on the

water heater will leak during the water heating cycle resulting in loss of energy. To prevent the build up of lime in the T&P valve

and damage to the water heater by pressure surges you must install an expansion tank on the cold water supply line. The thermal

expansion tank should have a minimum capacity of 4.5 U.S. gallons. It requires both T&P valves and expansion tanks for closed

system.

Multiple water heating system and/or a system with additional storage tank must be sized by thermal expansion tank

manufacturer.

WARNING CLOSED WATER SYSTEMS

PRESSURE BUILD-UP IN CLOSED WATER SYSTEMS