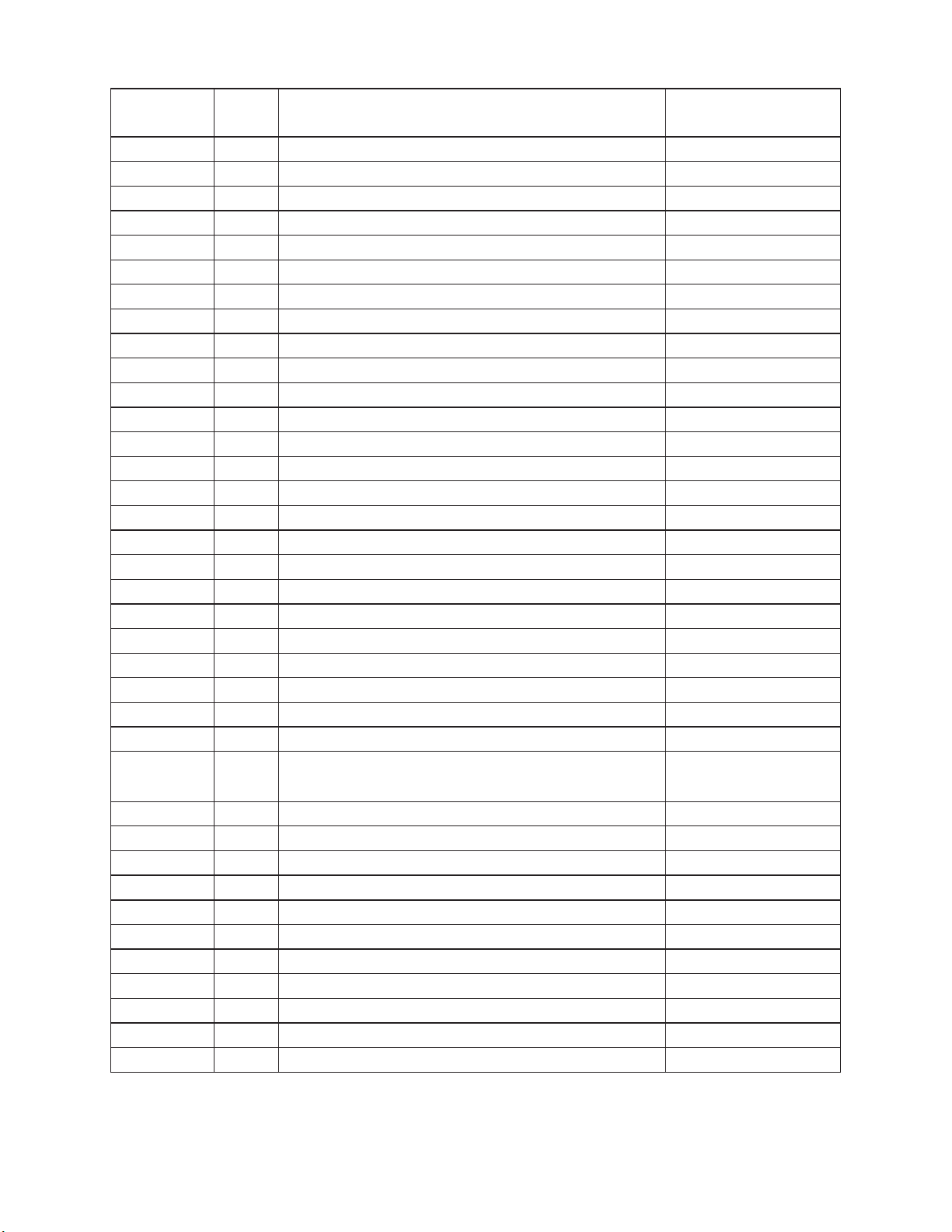

Position

#QTY Description Part Number

1 1 Reservoir 90L (Ver. 1.0) Not available

2 1 Round Nut w/ Collar Not available

3 1 Gauge (Thread type unknown) Not available

4 1 Seat Not available

5 1 Steel Tube Not available

6 1 O-ring (42.5 x 2.65) Not available

7 1 Handle w/ hook TIM-317-20

8 2 Screw w/ Chamfered End TIM-317-17

9 4 Acorn Nut TIM-317-6

10 4 Spring Washer TIM-317-41

11 4 Plain Washer TIM-317-5

12 2 Swivel/Caster Wheel (sold as pair) TIM-317-4

13 2 Elbow TIM-317-7

14 2 Nut TIM-317-8

15 1 Tube with Label TIM-317-9

16 1 Fill Cap TIM-390AS1-16

17 1 Gasket, Fill Cap TIM-390-GAST

18 1 Hex Head Screw Not available

19 1 Chain Not available

20 1 Steel Ring Not available

21 1 ¼” M x ¼” F Adapter Not available

22 1 ¼” M x ¼” F Ball Valve TIM-317-43

23 1 Elbow Adapter Not available

24 1 1/2" Ball Valve (1/2” FPT x ½” MPT) Not available

25 1 Safety Valve Not available

26 1 Connecting Hose(Discharge)

1/2" Hose 1/2” NPT(M) x 1/2” NPT(F) TIM-390-HOSE

27 1 Container See #30

28 1 Cap See #30

30 1 Tube (Set of #27 and #28) TIM-390-30

32 1 Funnel Not available

A1 Quick Coupler (¼” MPT) 23902-210

B1 Air Filter (¼” FPT x ¼” FPT) F-100

C1 Straight union adapter (1/4" NPT) TIM-1404-44

1 TIM-1501-88

E

D

1 1/4" (M) x 1/4" (M) adapter TIM-212-1

1 Manual TIM-390-INST

F1 Digital Meter Control Handle TIM-601-FM

90 Degree Union Adapter (1/2" NPT)