be necessary in milder weather, although monthly

cleanings may be enough in the coldest months.

Contact your local authority for information on how to

handle a chimney fire, and have a clearly-understood

plan to handle a chimney fire.

ASH DISPOSAL

Regularly inspect the ash build-up in your unit and

remove as necessary. Ashes can be removed from the

unit with a shovel and put them into the ash pan.

Caution: Never remove red-hot ashes from the

appliance; allow ashes to cool before dropping into

the ash pan. Ashes should be placed in a metal

container with an airtight lid. The ashes should be

placed on a noncombustible surface and completely

away from any combustible materials. The ashes

should remain in the airtight container until they

have completely cooled.

IMPORTANT: HELPFUL HINTS

AND TIPS WORTH REVIEWING

1. What is the correct way to start a fire?

• You will need small pieces of dry wood (kindling)

and paper. Use only newspaper or paper that has

not been coated or that has had materials glued or

applied to it. Never use coated or colored paper (such

as advertising flyers).

• Open the door of the wood stove.

• Crumple several pieces of paper, and place them in

the center of the firebox, directly on the firebricks of

the stove. Never use a grate to elevate the fire.

• Place small pieces of dry wood (kindling) over the

paper in the form of a“teepee.” This allows for good air

circulation, which is important for good combustion.

• Light the crumpled paper in two or three different

locations. NOTE: It is important to heat the air in the

stovepipe for draft to begin.

• Fully open the air control of the wood stove, and

close the door until it is just slightly open, allowing

for air to be introduced into the firebox. Never leave

the door fully open, as sparks from the kindling may

occur, causing injury. As the fire begins to burn the

kindling, some additional kindling may be needed to

sustain the fire. DO NOT add more paper after the fire

has started.

• Once the kindling has begun to burn, start adding

some small pieces of seasoned, dry firewood. NOTE:

Adding large pieces at the early stages will only serve

to smother the fire. Continue adding small pieces of

seasoned, dry firewood, keeping the door slightly

open until each piece starts to ignite. Remember to

always open the door slowly when placing wood into

the fire.

• Once the wood has started to ignite and the smoke

has reduced, close the stove door fully. (Reduction

of smoke is a good indication that the draft in the

chimney has begun, and good combustion is now

possible.) Larger pieces of seasoned, dry firewood can

now be added when there is sufficient space in the

firebox. Adjust the air control setting to your desired

setting.

• NOTE: The lower the air control setting, the longer

the burn time of the firewood.

2. How to reload your fireplace?

• Open the door and slide the ash tray outwards to

catch live coals that may fall. Poke the live coals with a

fire hook to remove the ash and place the new wood

on top of these coals.

• Never open the door while the fire is burning

vigorously. Wait until the fire calms down.

• Slide the air control lever to“HIGH”for a few minutes.

Once the flames are vigorous, move the air control

lever towards“LOW” to reduce air intake and achieve

the desired heat.

3. What type of wood is best to use as firewood?

• Dry, seasoned hardwood should be used. Avoid

green, unseasoned wood. Green wood, besides

burning at only 60% of the fuel value of dry seasoned

wood, will deposit creosote on the inside of the stove

and along to inside of the chimney.

4. What does dry, seasoned wood mean, and what

is considered to be hardwood?

• Wood that has been dried for a period of one year

in a well-ventilated and sheltered area is considered

dry, seasoned wood. Hardwoods generally come

from slow-growth trees, such as Oak or Fir. Softwoods

generally come from fast-growth trees, such as Pine

or Spruce.

5. Will following the steps listed above result in a

perfect fire every time?

• A good answer would be “most of the time.” There

are many variables that can affect your rate of success

when starting a fire, and experience will teach you

how to deal with the variables. This section of the

manual will cover some of the variables that can

affect a fire, and time and patience will contribute to

your ability to start a good fire consistently.

6. Why can’t I get the fire lit?

• Damp or wet wood and poor draft are the main

reasons for poor results when starting a fire.

Remember to always use dry, seasoned wood for your

fire. Even wood that has been dried (seasoned) for a

long period of time will be difficult to light if it has

gotten wet.

7. Why is there always a large quantity of thick

black smoke in the firebox?

• A large quantity of thick black smoke in the firebox

is a possible indication that you have poor draft.

8. Is it normal for soot to cover the glass at the

beginning of a fire?

• This stove has been built with an air wash system

that will help keep the glass clear when the firebox

has reached a good operating temperature, and

also has a good draft. Cold firebox temperature and

poor draft cause soot to form on the glass. Once the

firebox temperature and the draft increase, the soot

should burn off.

9. What is “draft?”

• Draft is the ability of the chimney to exhaust draw

by-products produced during the normal process of

combustion.

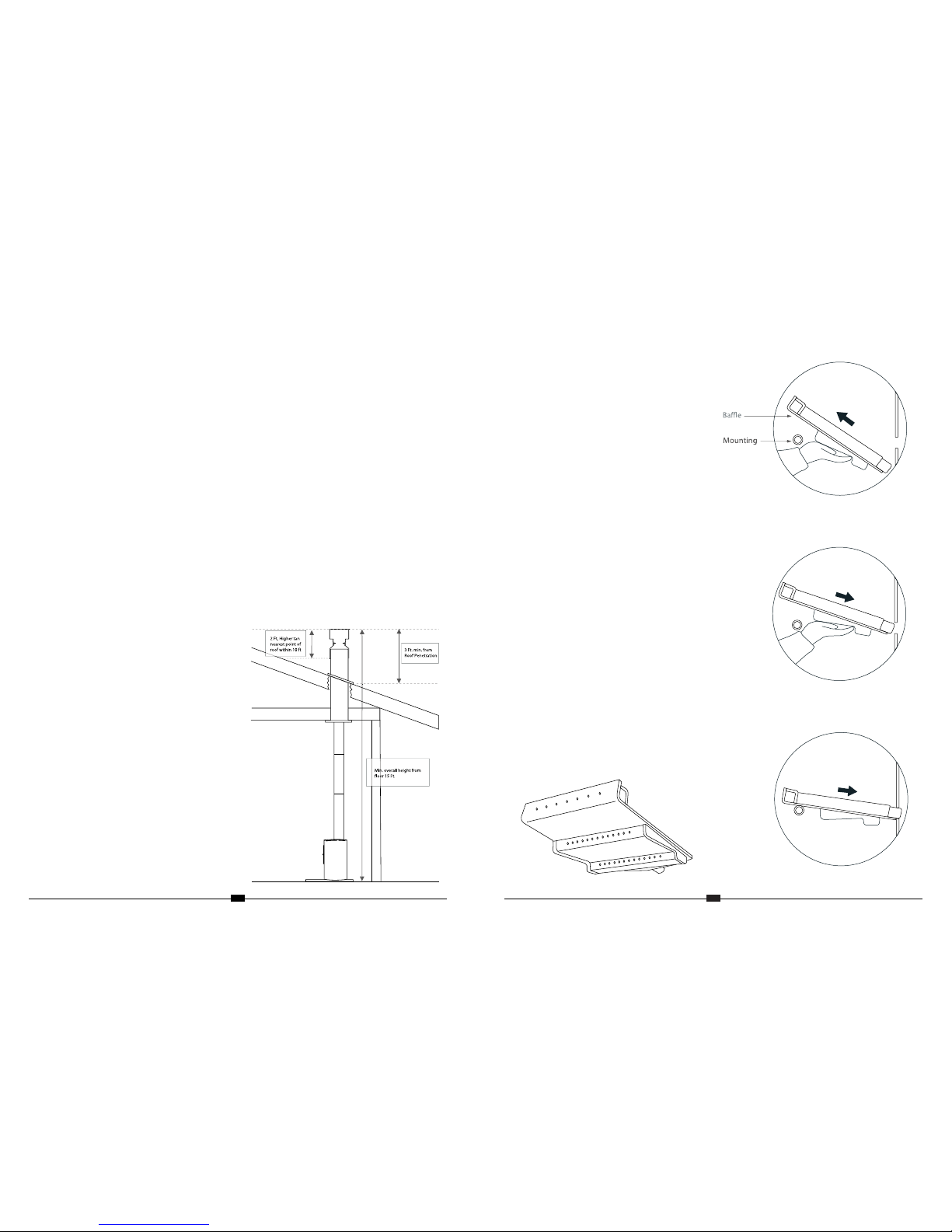

10. What can cause a poor draft?

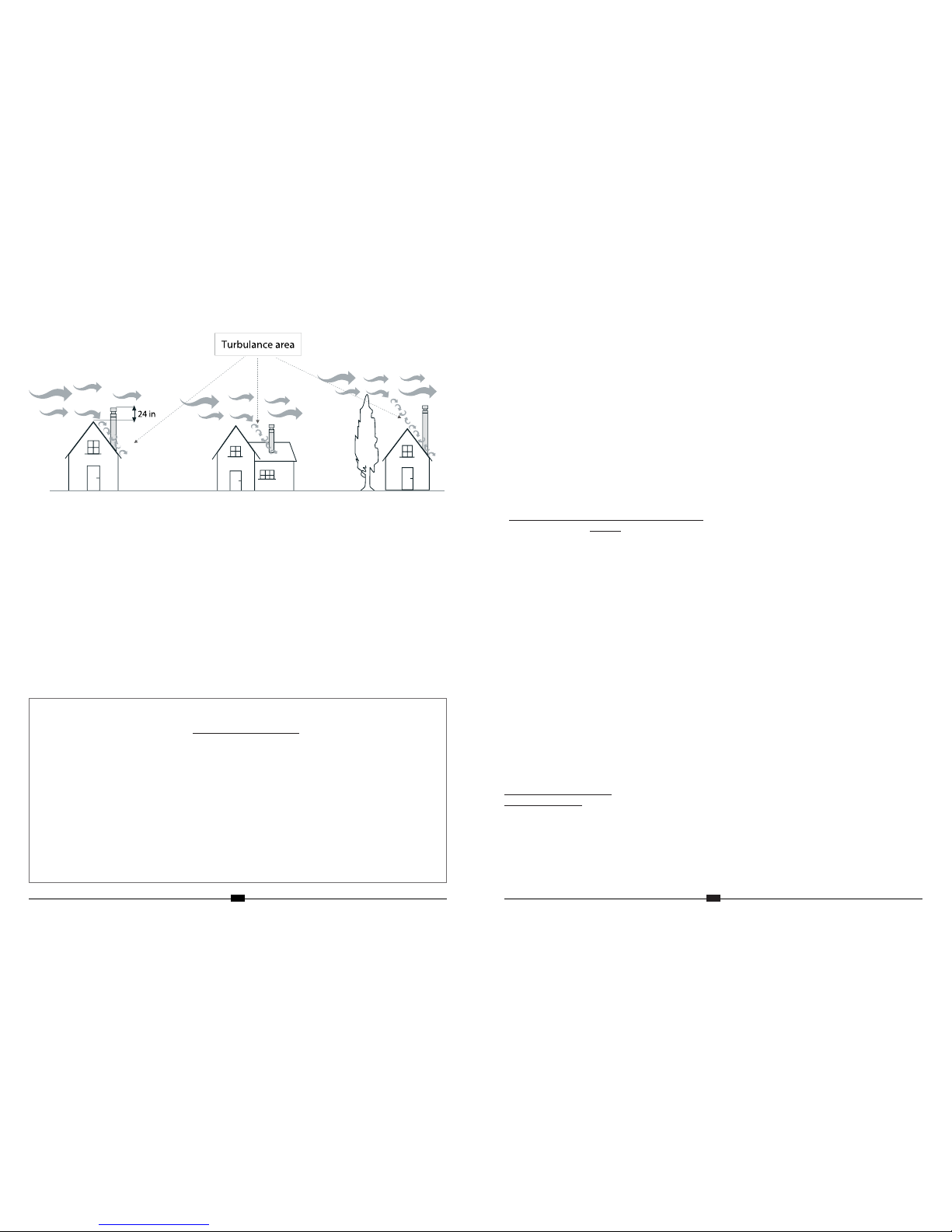

• If wind collides with an obstacle, there will be

turbulence that can cause smoke to blow back

down the flue (down draft). To correct this situation,

increase the length of the flue so that it projects over

the turbulence area.

• Thereare severalcommonfactorsthatcan contribute

to poor draft:

A. Atmospheric Pressure and Air Supply

Atmospheric pressure affecting the draft from a

chimney can be outside the home, inside the home,

or both. Outside the home, a high-pressure (clear

and cool) day generally creates a better draft in the

chimney than a low-pressure (overcast and damp)

day. Inside the home, household appliances, such

as forced-air furnaces or clothes dryers, compete

for air, often resulting in inadequate amounts of air

available to fuel a fire and creating a condition known

as negative pressure. Extreme conditions of negative

pressure can cause the combustion by-products to

be drawn from the chimney and into the house. This

condition is commonly known as“down drafting.”

There are several factors that can affect the amount

of air available in the home. Increased amounts of

insulation, vinyl windows, extra caulking in various

places and door seals can all keep heat in, but may

also make a home too airtight. If you are in doubt as

to whether or not there is sufficient air in your home

for your stove, refrain from using those appliances

known to consume air when possible, or open a door

or a window to allow some air to enter the home.

B. Environmental Conditions

High trees, a low-lying house location (such as in a

valley), tall buildings or structures surrounding your

house and even windy conditions can cause pool

draft or down drafting.

16 17