Page 2 of 15 503158 ISSUE 3 EDCR21694

Table of Contents

1INTRODUCTION.....................................................................................................................................................................................4

2SAFETY, WARNINGS AND CAUTIONS ................................................................................................................................................5

2.1WARNINGS AND CAUTIONS ..........................................................................................................................................................5

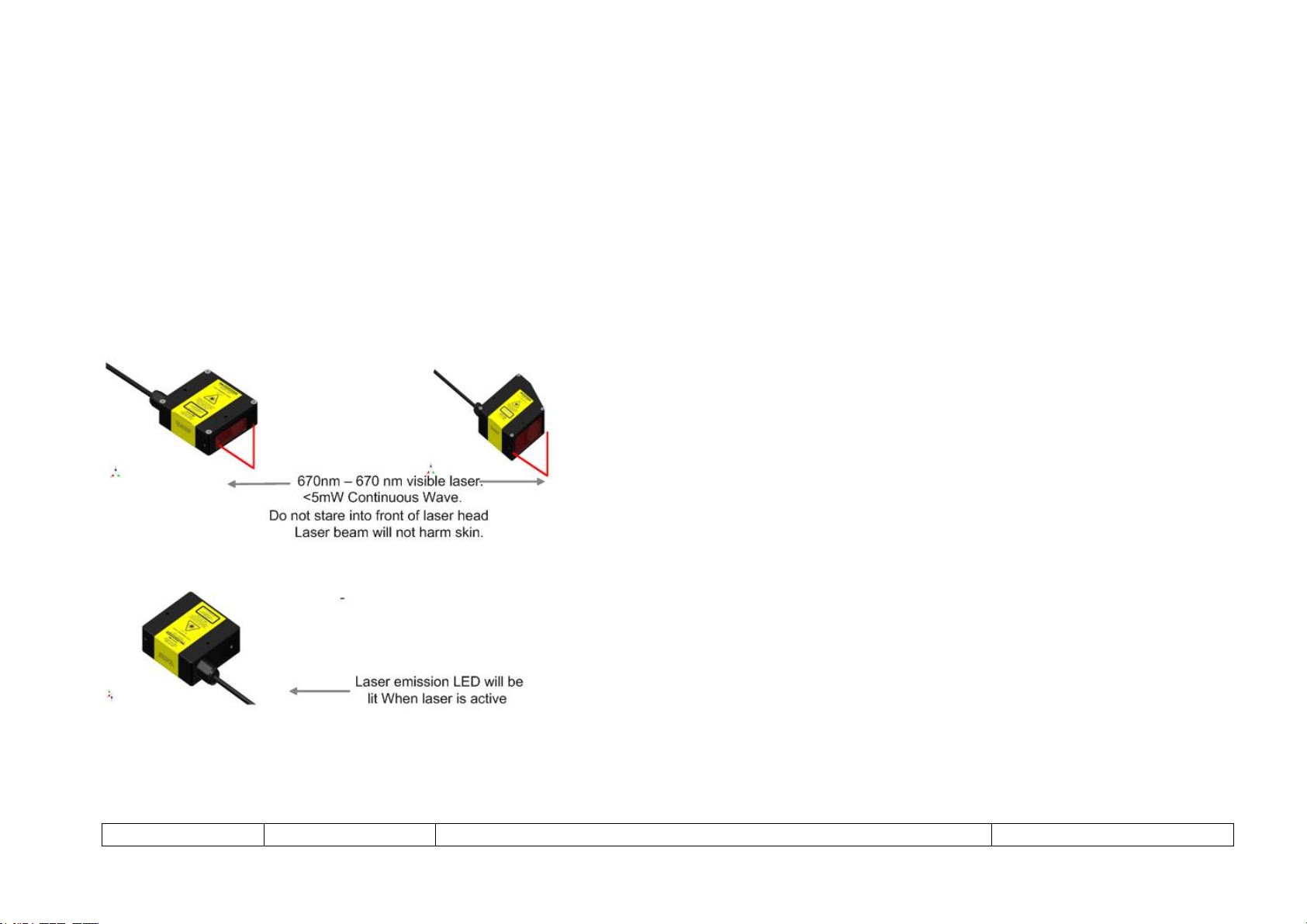

2.2SAFETY FEATURES........................................................................................................................................................................8

2.3HAZARD AREAS..............................................................................................................................................................................8

3OPERATING PRINCIPLES.....................................................................................................................................................................9

3.1SYSTEM DESCRIPTION..................................................................................................................................................................9

3.2INSTALLATION AND SET UP..........................................................................................................................................................9

3.2.1Environments that are known to cause problems.......................................................................................................................9

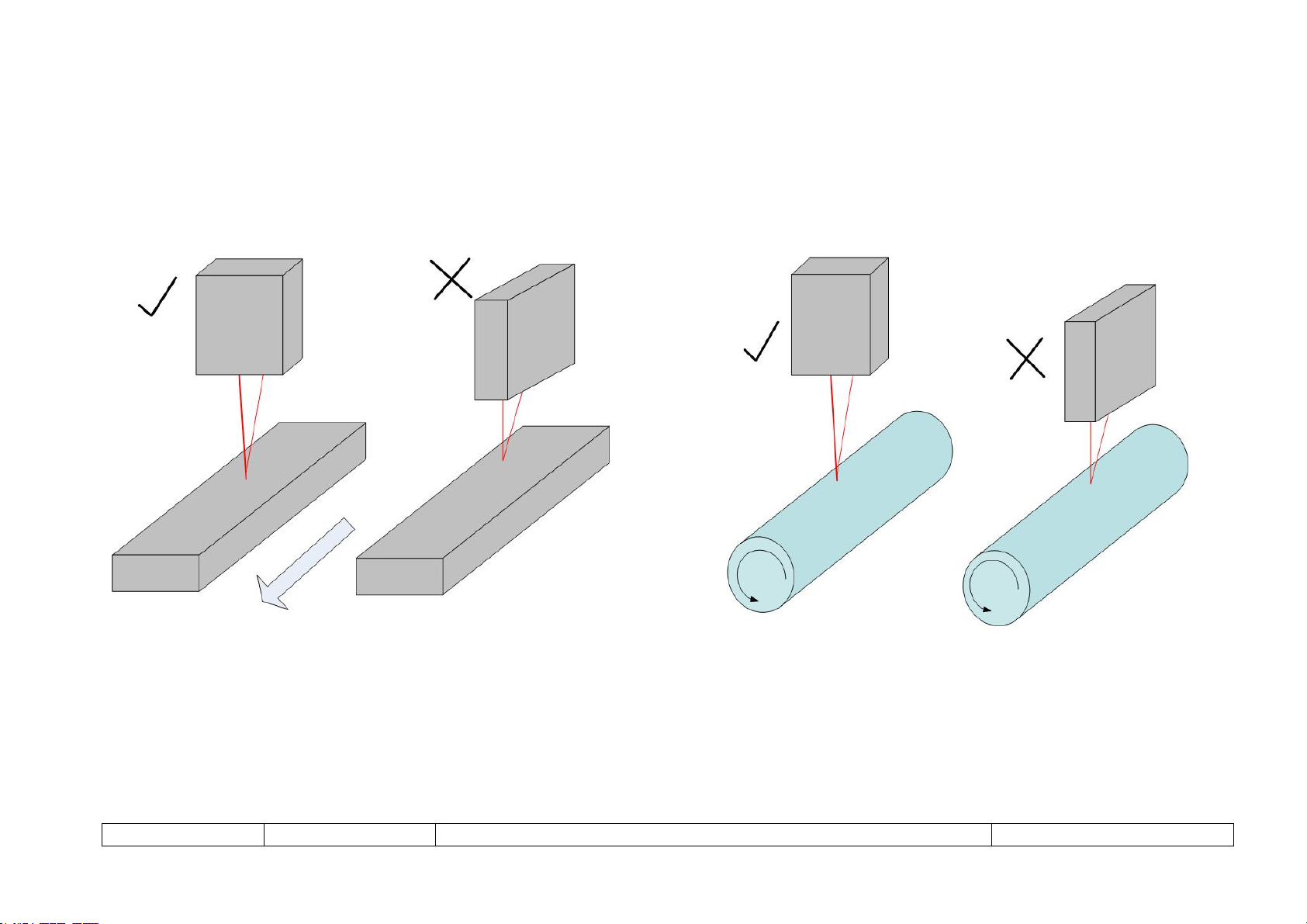

3.2.2Head Orientation ......................................................................................................................................................................10

3.2.2.1Moving Targets ..................................................................................................................................................................10

3.2.2.2Slots and Walls ..................................................................................................................................................................11

3.2.3Mounting...................................................................................................................................................................................12

3.3 LED INDICATOR, DIFFUSE AND SPECULAR MODE .....................................................................................................................13

4KEY FEATURES...................................................................................................................................................................................14

4.1.1Laser Head Filter......................................................................................................................................................................14

4.1.2Level Cut Time .........................................................................................................................................................................14

4.1.3Laser Beam Control..................................................................................................................................................................15

5Orbit and ORBIT ACS INTERFACES ...................................................................................................................................................15