1

CONTENTS

Product Features and Specifications ......................................................... 1

Installation Requirement..…………………………...…..…….………………………………………….2

Steps of Installation...………………..................…………………............................. 3

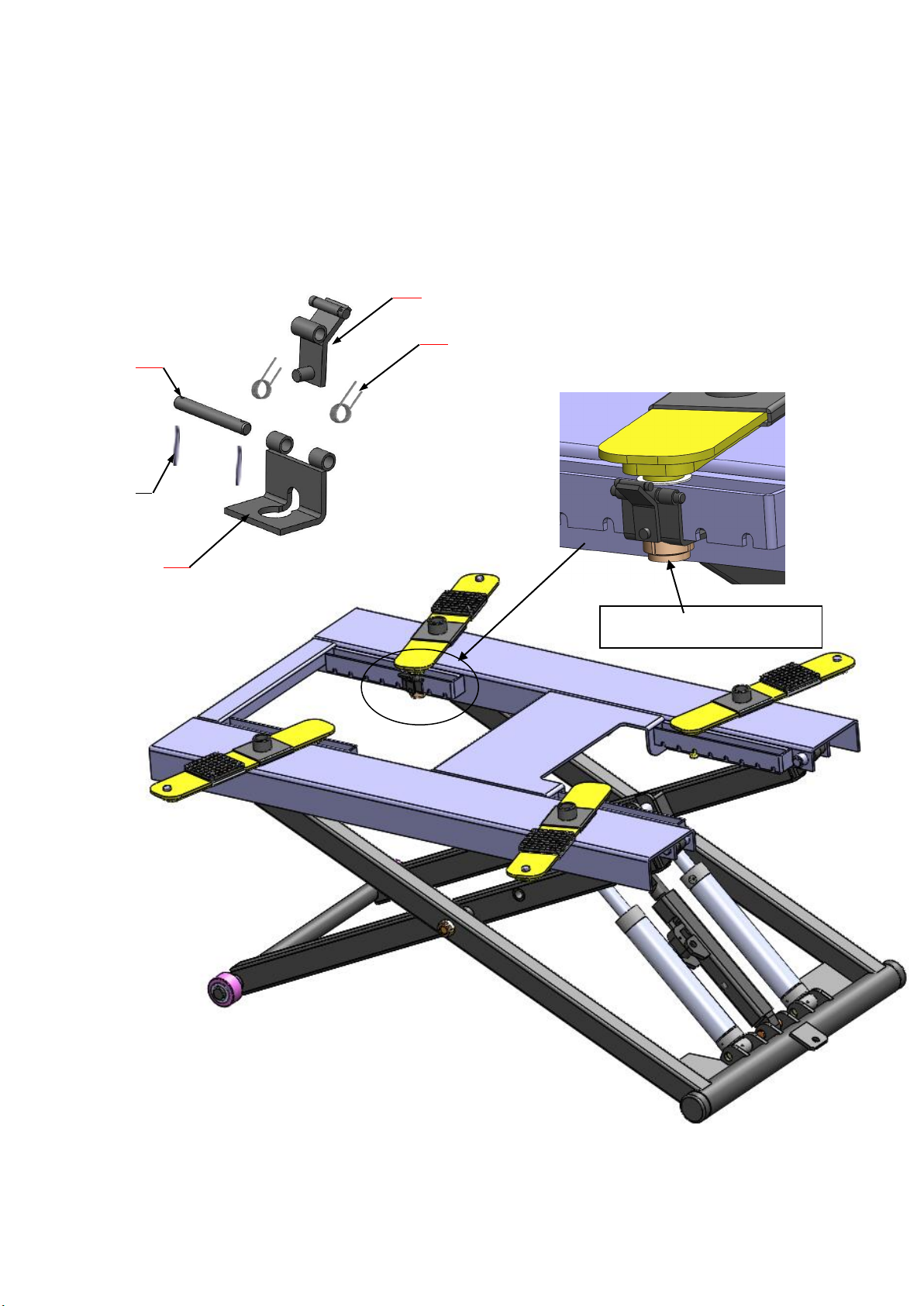

Exploded View...……………………………..………….…...….………………………………………….. 9

Operation Instruction..……………………………………..…..…………………………………………..12

Maintenance …………………………………………………………………………………………………….. 13

Trouble Shooting ...……………………………………….....…………………………………………….. 14

MR06 Parts List ...……………………………………………..….…………………………………………. 15