MAN-X5L-ENG-01 2ⓒ 2016 All Material Handling

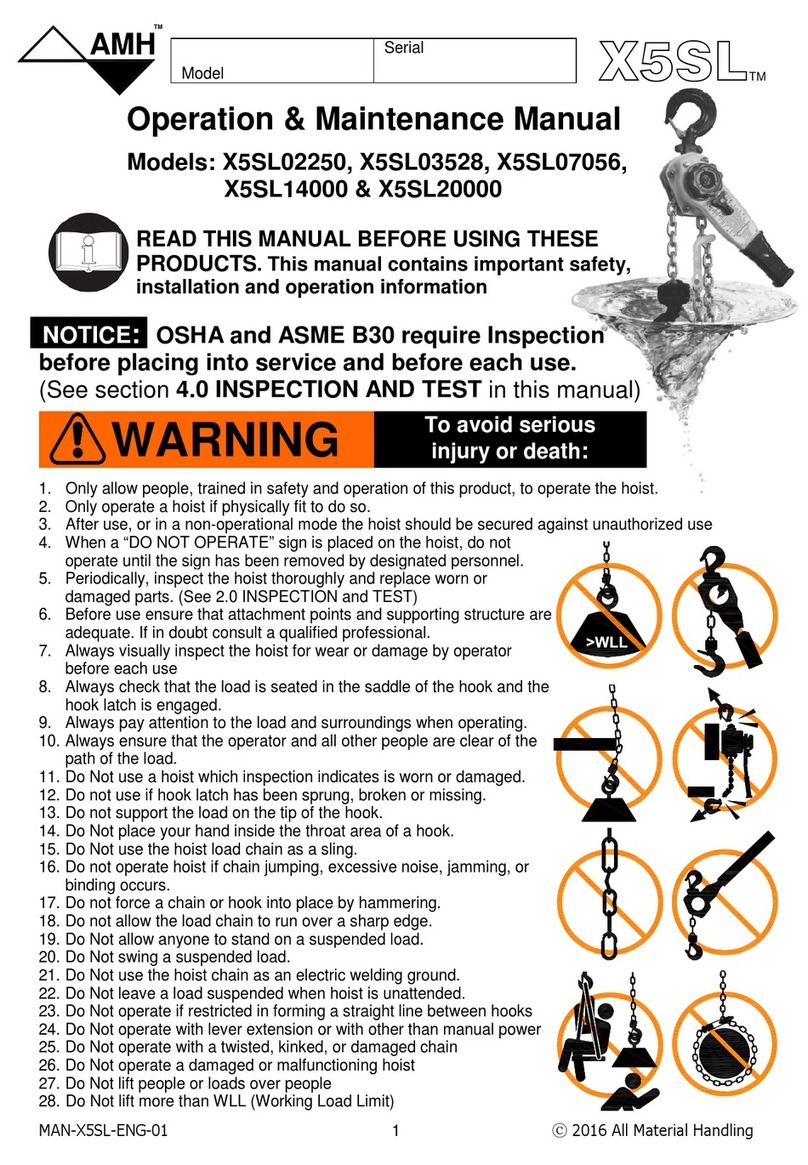

HOIST NAMEPLATE with basic warnings and information as required by ASME B30:

It is recommended to copy; Model, and Serial number into the

blocks on top of the cover of this manual. Make a copy of this

manual available to all operators. Note that the “Overload

Protection” label will only appear on units so equipped. Below,

the warnings are translated:

WARNING

To avoid serious injury or death

Read manual before operating

Do Not remove or obscure this label

Do Not operate if restricted in forming straight line between hooks

Do Not operate with lever extension or with other than

manual power

Do Not operate with a twisted, kinked, or damaged chain

Do Not lift people or loads over people

Do Not operate a damaged or malfunctioning hoist

Do Not lift more than WLL

1.0 OPERATION:

The operator must read and understand Warnings and operational

instructions in this manual and as displayed on the hoist.

Set up using free chain mode to pull chain in or out by hand

1. Under no load, move the selector to neutral “N” position.

2. Pull the hand wheel out then counterclockwise (CCW) to hold

position. (Do Not attempt to pull out or rotate when hoist is loaded)

3. Pull chain in or out by hand. (Too quick or fast and the brake

will set and the set up must be repeated.)

4. Attach hook to load.

Set the Brake and prepare to load

5. Quick pull on the tail chain to tighten the chain against the load

or turn the hand wheel clockwise (CW). The hand wheel will then

return to the “in-position” when the chain is snug against the

load. (Without load, hold the chain with bottom hook and turn the

hand wheel clockwise CW)

6. Turn the selector to the up “U” position.

Load the hoist to begin lift or pull.

7. Ratchet the lever in the clockwise (CW) direction to lift or pull.

Move selector to Down “D” and ratchet in the counterclockwise

(CCW) direction to lower the load.

8. Confirm proper operation by Lifting or pulling until the full load

is suspended. Stop and check if rigging and the hoist holds the

load without slipping. If confirmed then continue the lift or pull.

Detaching the Load

9. Secure the load.

10. Release tension on the chain by turning the selector to down

“D” and ratchet the lever in the counterclockwise (CCW)

direction until enough slack to detach the hook. Pull chain out

by hand to provide resistance to allow the lever to ratchet.

Instruction

Label

Hand

Wheel

Selector

Name

Plate

Tail

Chain

Stop

Overload

Protection

Clutch Label

(if equipped)