- 3 -

A. General Information and Safety Instructions:

Before you begin –Safety instructions

Prior to installation, operation, maintenance or any other type of action done on the filter, read carefully the

installation and operation instructions.

During installation, operation or maintenance of the filter, all conventional safety instructions should be

observed in order to avoid danger to workers, the public or to property in the vicinity.

Please note: The filter enters automatically without any warning into a flushing mode.

No changes or modification to the equipment are permitted without a written notification given by the

manufacturer or by its representative on his behalf.

Service the filter according to the detailed Instructions provided with the filter by the manufacturer and

according to the description given in this manual.

Electric wiring should be performed by an authorized electrician only, using only standard and approved

components.

If due to site constrains the control panel is installed with no line-of sight with the filter an additional Power Cut-

off Switch should be installed near each filter unit before any attempt to service the filter is done.

Extra safety devices should be installed on hot water applications to avoid skin burn danger.

Disconnect the filter from power supply before performing any service, maintenance or any non-regular

operation action.

Loosening or unscrewing bolts should be done only after the pressure in the filter had been released.

Avoid splashing and water leaking so as to minimize slipping, electrifying or damage to the equipment, caused by

moisture.

Always open and close valves slowly and gradually.

Remove grease and fat material residues in order to avoid slipping.

Re-assemble any protection covers or protection mechanisms removed during service or maintenance

operations before re-operating the filter.

Manual cleaning of filter media using high water pressure or steam should be performed in accordance with the

cleaning system instructions and without endangering the operator or the vicinity.

Manual cleaning of any filter element using acid or other chemical agents should be performed in accordance

with the relevant material safety instructions and without endangering the operator or the vicinity.

While using lifting equipment, make sure that the filter or the lifted part is chained securely and in a safe

manner.

Do not leave lifted equipment if there is no necessity.

Avoid working below lifted equipment.

Wear a safety helmet while using lifting equipment.

Arrange suitable lighting at the area of the filter to enable good visibility and safe maintenance.

Provide suitable platforms and safety barriers to enable easy access to the filter without climbing on pipes and

other equipment.

Check and re-tighten all bolts after finishing the maintenance or service work.

Always maintain regular safety instructions and good engineering practices while working in the filter’s vicinity.

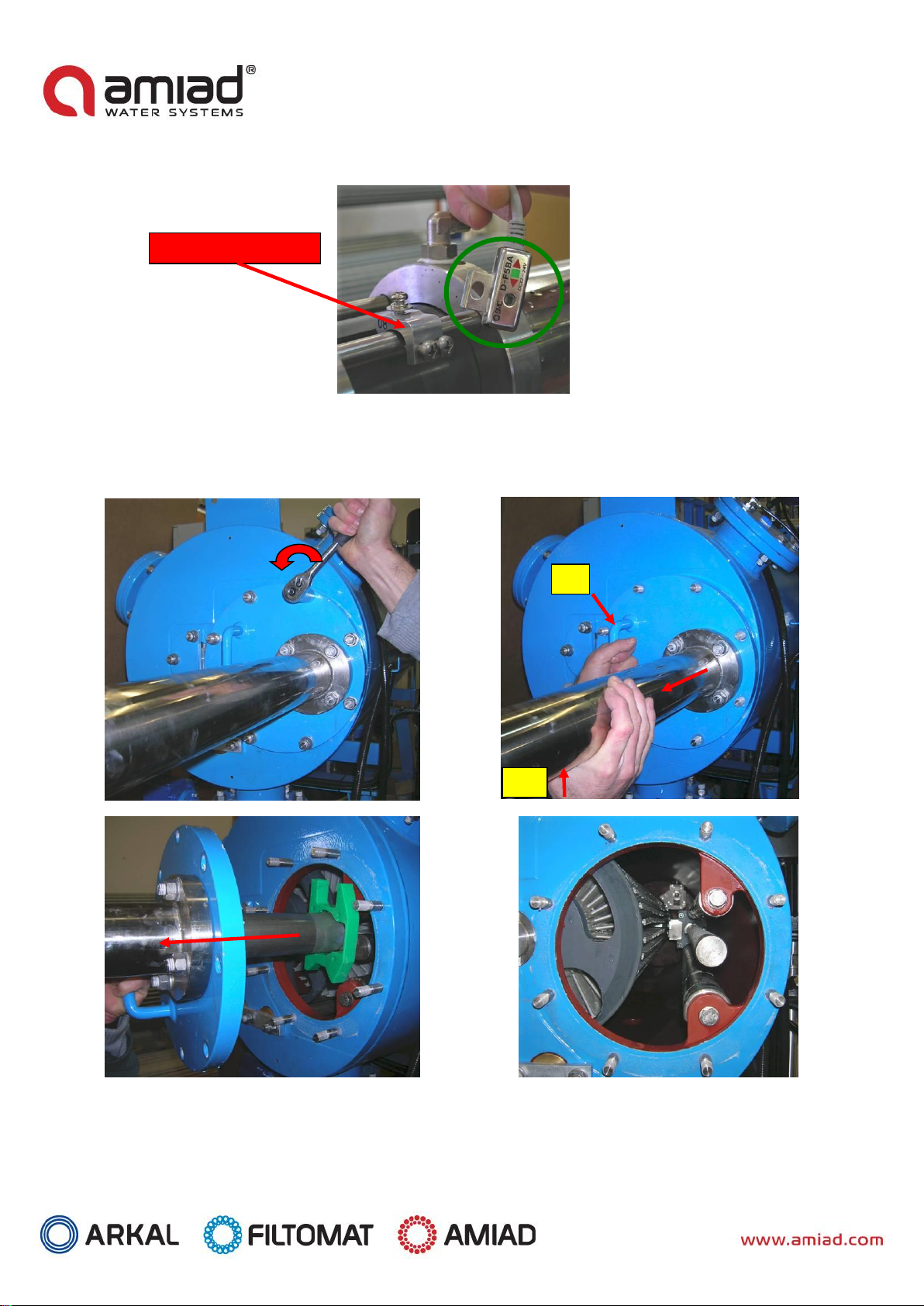

Required tools:

In addition to a regular standard tool box, 2 special tools are required for a successful completion of the cassette

replacing process:

1. MTG/AMF grooved Cassette Alignment Ring - catalogue number –65-8040--4004