EBS 10K Flat Lid 910101-000595 / 07.2019 Page 10 of 28

INSTALLATION

Design recommendations

1. If flow increases and pressure drops dramatically for a long period of time during network filling-up, it is recommended that a

pressure sustaining valve is installed downstream of the filter. The pressure sustaining valve will ensure a controlled filling-up

of the line.

2. If continual water flow is essential even during maintenance period, it is recommended that a manual or automatic by-pass is

installed, and the isolating valves will be used to isolate each filter.

3. In places where there is an expected temporary worsening of water quality, it is possible to operate an emergency flushing

program. In order to do so, a hydraulic controlled valve has to be installed downstream of the filter. For details, please

consult the manufacturer.

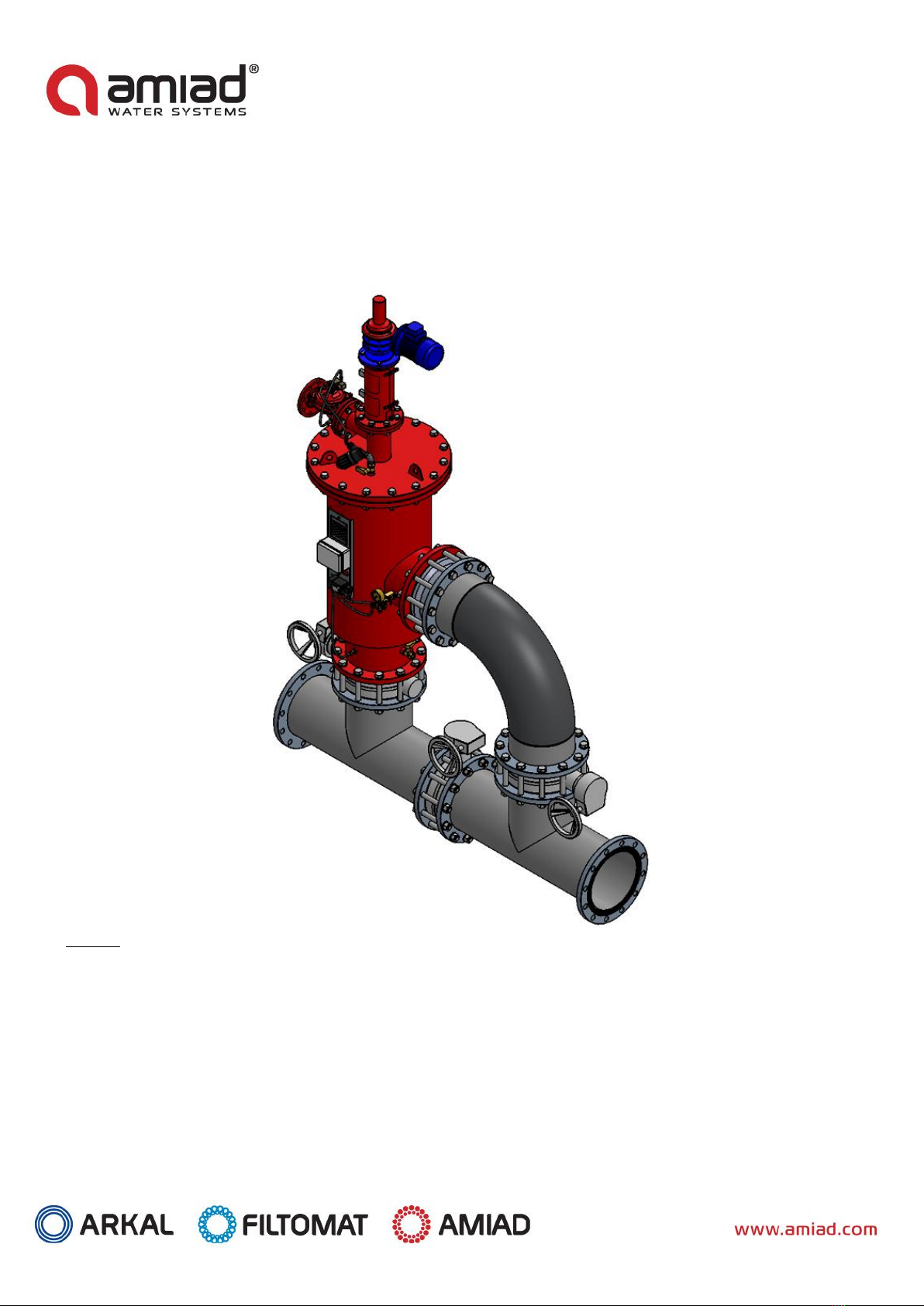

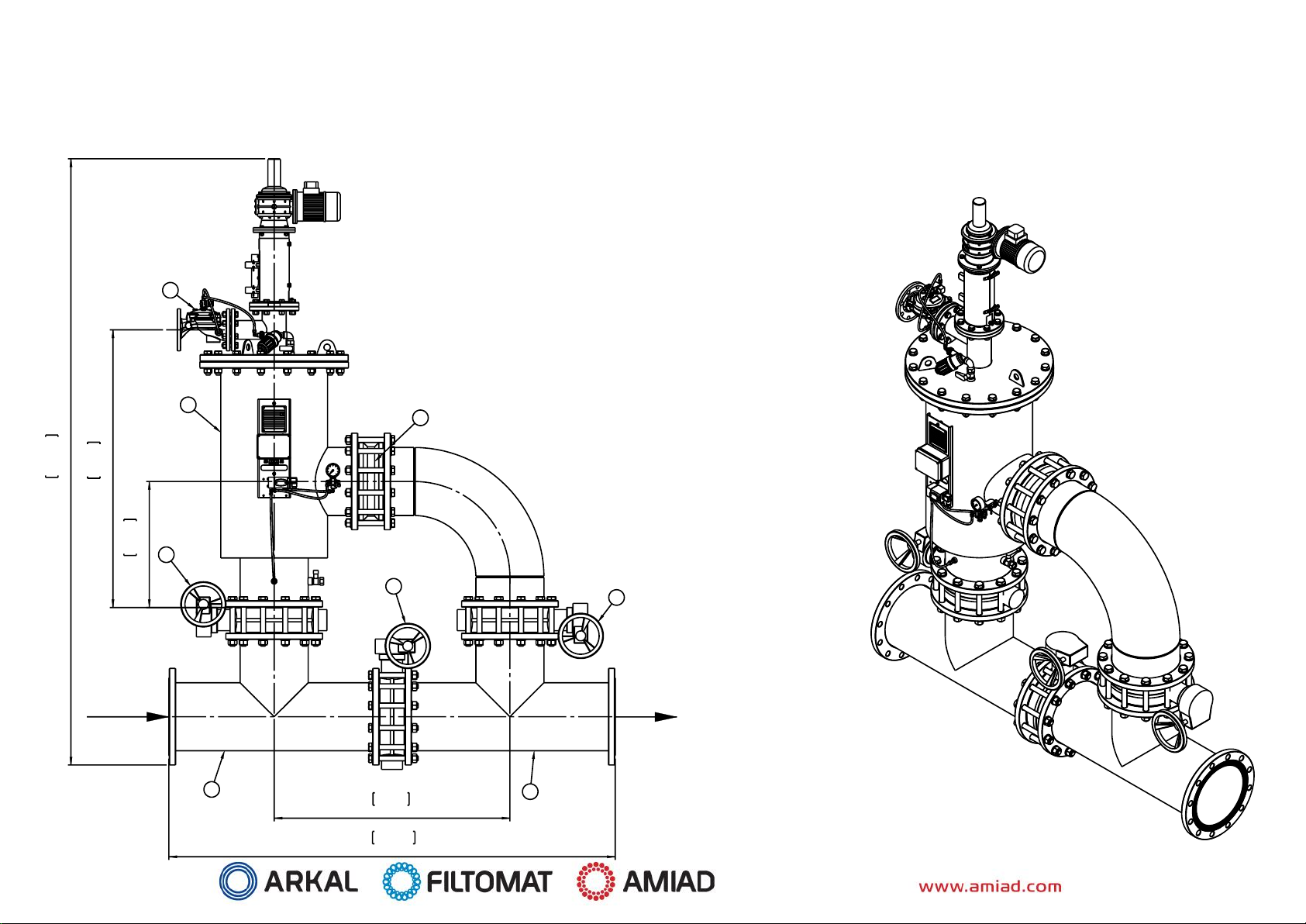

Installation instructions

1. Before beginning the installation process, carefully read the safety instructions in chapter 2 of this document and make sure

that all the workers at the installation site are fully aware of and comply with, these and any other local safety instructions.

2. Select a convenient location for the installation of the filter where operation and maintenance will be optimal. It is

recommended that a standard and safe lifting auxiliary is available for maintenance.

3. Install the filter vertically. Please note that a minimum clearance of 300 mm (12 In.) (Not including a crane) is required in

order to allow disassembly of the unit.

4. Ensure that the direction of flow is aligned with the arrows marked on the filter housing. (Flow outlet will always be from the

side; flow inlet is from the bottom).

5. Installation of a mechanical non-return valve downstream of the filter is required.

6. If possible, prior to installing the filter, thoroughly flush the main line at the connection point in order to remove large objects

that may damage the filter’s internal mechanism.

7. Install a drainage pipe to the exhaust valve. Minimum 3" diameter for a maximum pipe length of 20 meters (60 feet), for

longer drainage, 4" pipe diameter must be used for a maximum length of 40 meters (120 feet). Please note that no restriction

is allowed on the drainage pipe. For special applications, please consult the manufacturer.

8. If the system is designed to operate with working pressure higher than 4 bar (56 psi), it is recommended that a manual

valve is installed on the exhaust pipe, in order to enable regulation of the flushing flow rate & pressure.

9. The user should arrange suitable lighting in the vicinity of the filter to enable good visibility and safe maintenance.

10. The user should arrange suitable platforms and safety barriers to enable easy access to the filter without climbing on pipes

and other equipment. All such equipment should comply with the safety clauses of the relevant local standards.

IMPORTANT!!

Prevent static backpressure or reverse flow through the filter.

Install a non-return valve at the outlet of the filter.

Install a manual or a hydraulic valve downstream of the filter.

Electric wiring

1. All electrical works at the installation site must be done by a qualified and authorized electrician only. Make sure that this

electrician is fully aware of all the relevant safety instructions.

2. Install the control board in a dry and protected place (In out-door installation sites make sure to use a special control board

for out-door installation).

3. Power connection to the control board:

a. Connect a three-phase voltage source through a semi-automatic switch, or 16 Amp. fuse to the L1 L2 L3 inlet at the

terminal strip in the control board.

b. Earth the control board.

4. Power connection to the motor: