PPMB1XX

3/47 ppmb1xx_g_en_105

Contents History of revisions.........................................................................................5

Related documentation...................................................................................5

1. Introduction..........................................................................................6

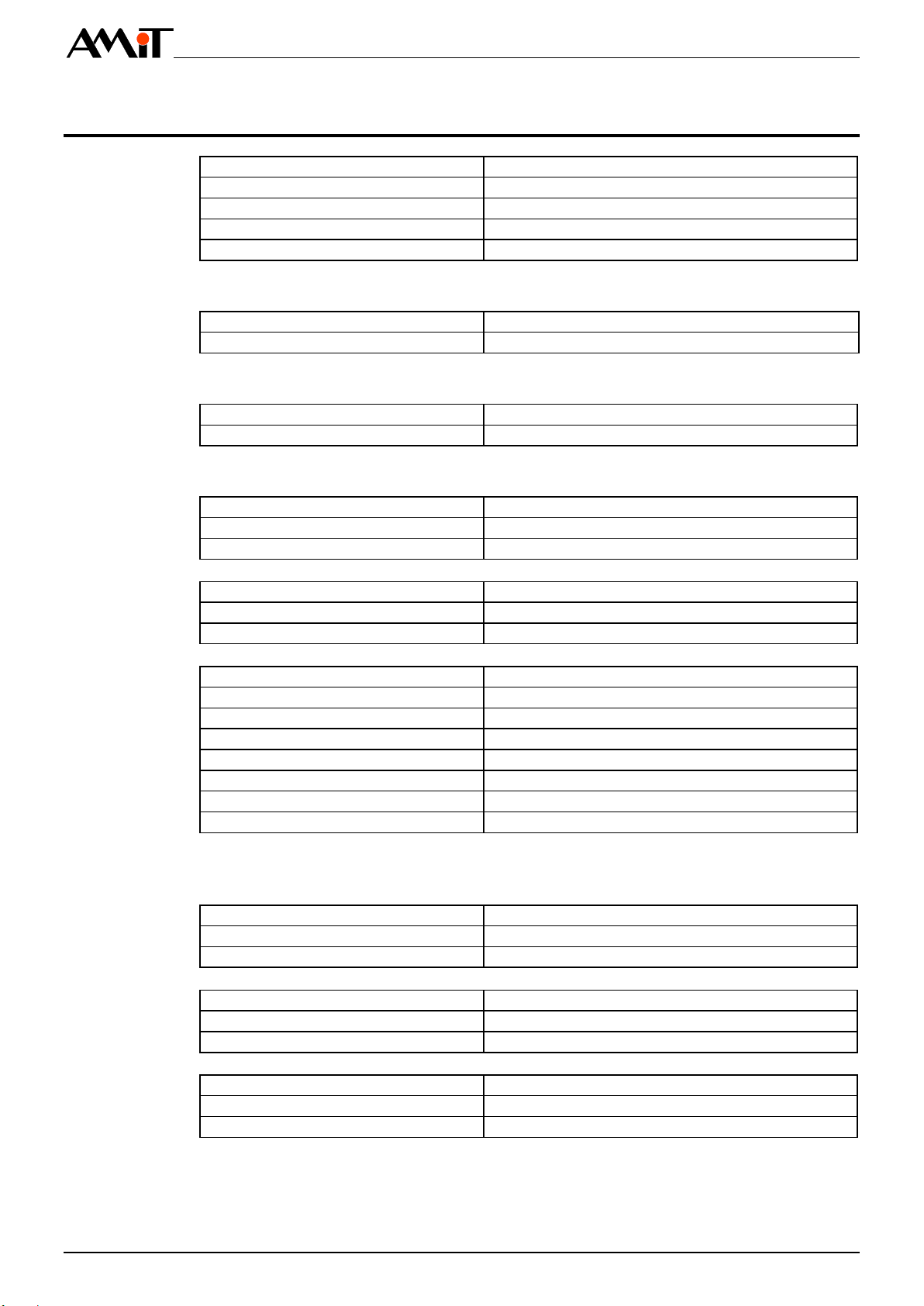

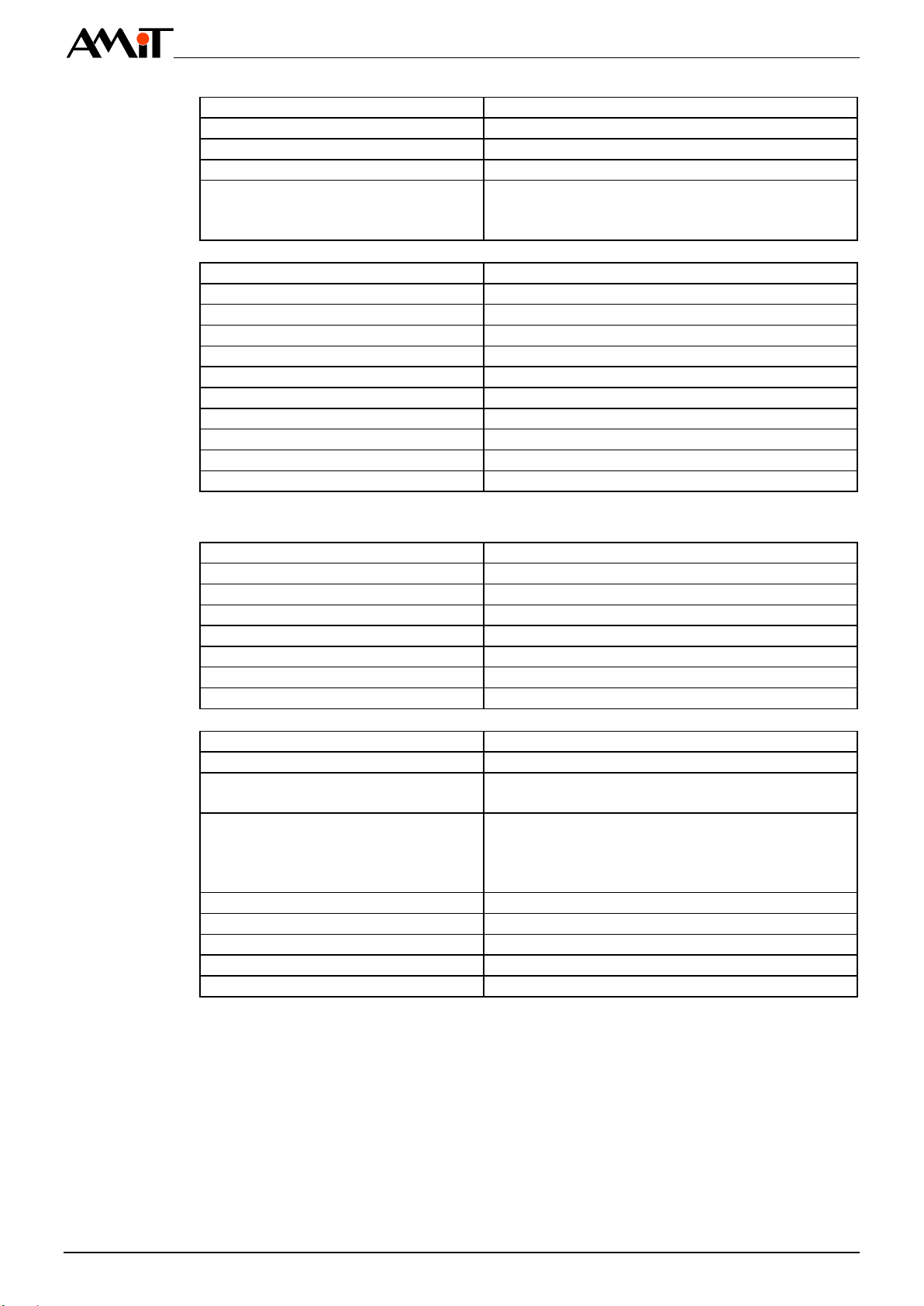

2. Technical parameters..........................................................................7

2.1. Possible variants ..........................................................................................10

2.2. Dimensions...................................................................................................11

2.3. Recommended drawing symbol ...................................................................12

2.4. Block diagram...............................................................................................13

2.5. Temperature dependence............................................................................13

3. Product designation ..........................................................................14

4. Conformity assessment ....................................................................15

4.1. Other tests....................................................................................................16

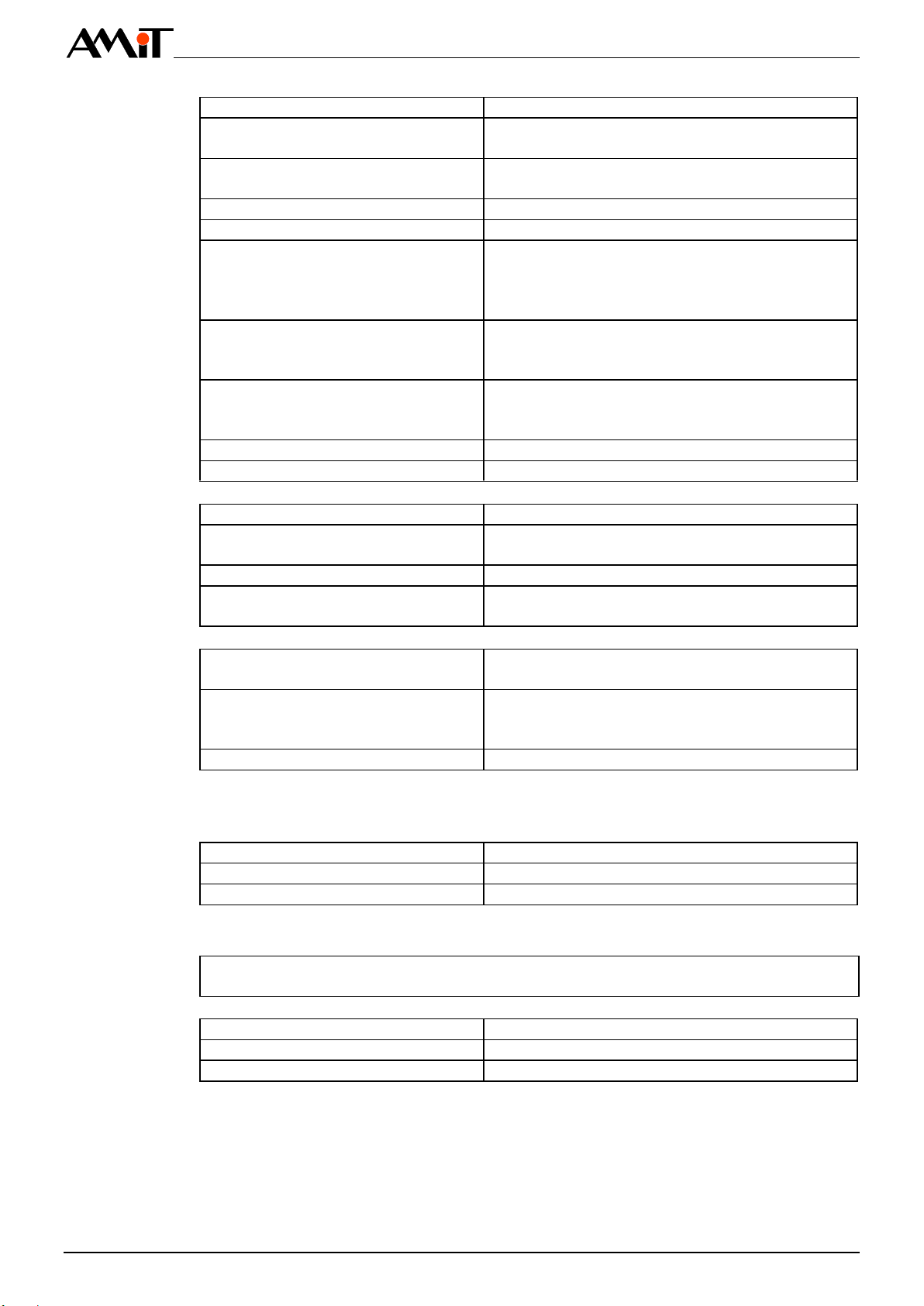

5. Power supply......................................................................................17

5.1. Computer start up and shut down.................................................................18

5.1.1 SB input is active..........................................................................................18

5.1.2 SB input is not used......................................................................................20

6. Digital inputs / outputs.......................................................................21

7. Communication lines and peripherals.............................................23

7.1. Video output.................................................................................................23

7.2. RS232 ..........................................................................................................24

7.3. Ethernet........................................................................................................25

7.3.1 Wiring connector M12 4-pin, 10 / 100 Mbps..................................................26

7.3.2 Wiring connector M12 8-pin, 10 / 100 Mbps..................................................27

7.3.3 Wiring connector M12 8-pin, 1000 Mbps......................................................28

7.3.4 Wiring connector RJ-45, 100 Mbps ..............................................................29

7.3.5 Wiring connector RJ-45, 1000 Mbps ............................................................30

7.4. USB..............................................................................................................30

7.5. User button...................................................................................................31

7.6. Indication LED..............................................................................................31

7.6.1 Variant with RJ45 connector –2 LEDs.........................................................32

7.6.2 Variant with M12 connector –4 LEDs ..........................................................32

8. Data carriers.......................................................................................34

8.1. System disk..................................................................................................34

8.2. Recording disks............................................................................................34

8.2.1 HDD..............................................................................................................34

8.2.2 SSD..............................................................................................................35

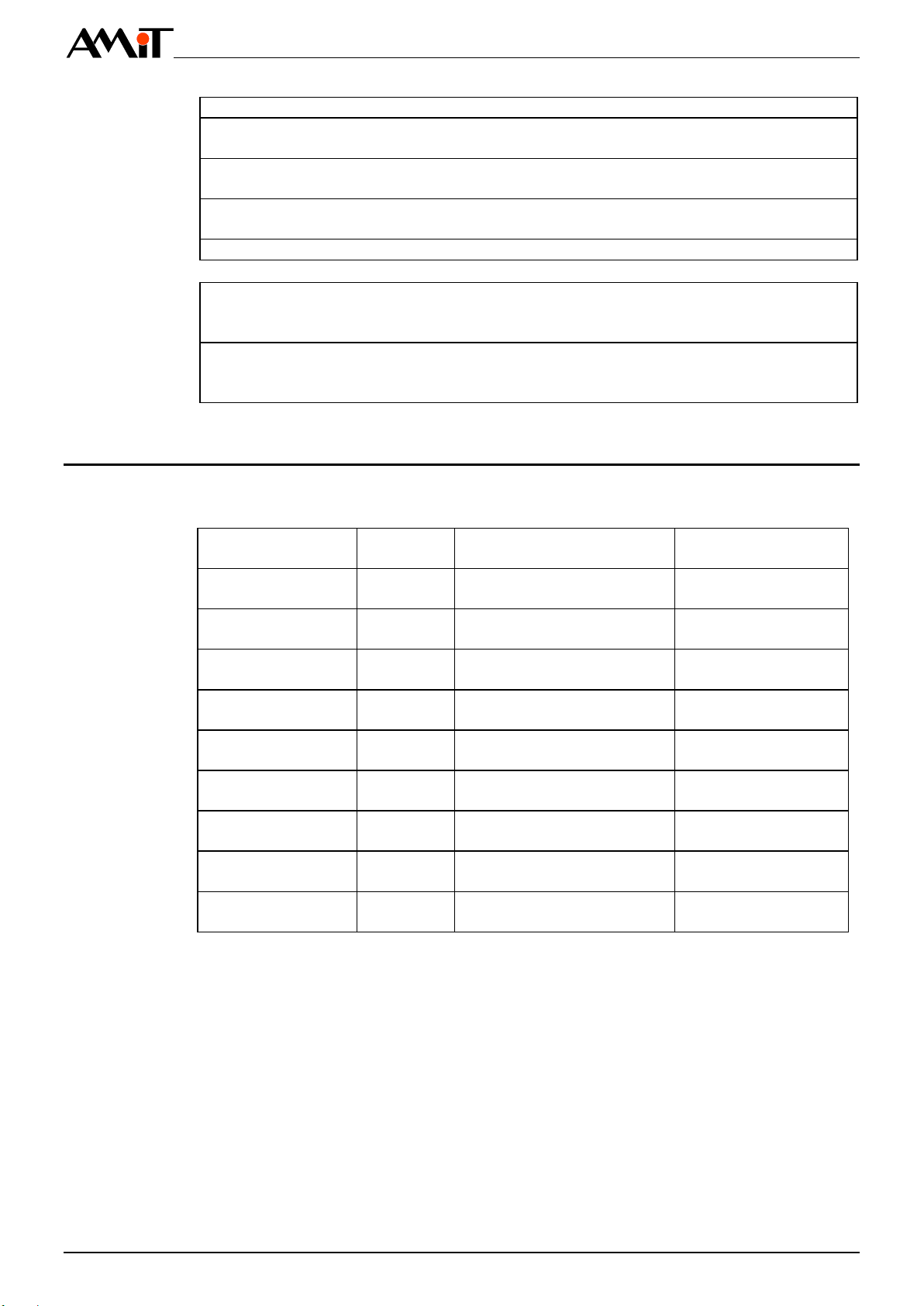

9. Mounting.............................................................................................36

9.1. Mounting instructions....................................................................................36

9.2. Cabling.........................................................................................................38

9.3. Mounting apertures.......................................................................................39

9.4. Handling the disks........................................................................................40

9.4.1 Plug-in module manipulation ........................................................................40

9.4.2 Plug-in module disk change .........................................................................40