4.3.5 Project planning for forced air flow .................................................................. 68

4.4 Mains supply ................................................................................................................ 72

5 Installation TITANUS PRO·SENS®.............................................................................. 73

5.1 General ........................................................................................................................ 73

5.2 Opening the TITANUS PRO·SENS®........................................................................... 74

5.3 Settings ........................................................................................................................ 75

5.3.1 Detector module............................................................................................... 75

5.4 Installation of the reset board....................................................................................... 84

5.5 Mounting Location........................................................................................................ 86

5.5.1 Fixing of the air sampling system TITANUS PRO·SENS®.............................. 86

5.5.2 Connection of the air sampling pipe ................................................................ 88

5.6 Electrical connection .................................................................................................... 89

5.6.1 Connection to F.D.C.I.E. , with reset button .................................................... 90

5.6.2 Connection of several TITANUS PRO·SENS® with reset button..................... 91

5.6.3 Connection to F.D.C.I.E., with reset board ...................................................... 92

5.7 Installation of the second detector module .................................................................. 93

5.8 Response indicator -electrical connection ................................................................... 95

5.9 Data Log....................................................................................................................... 96

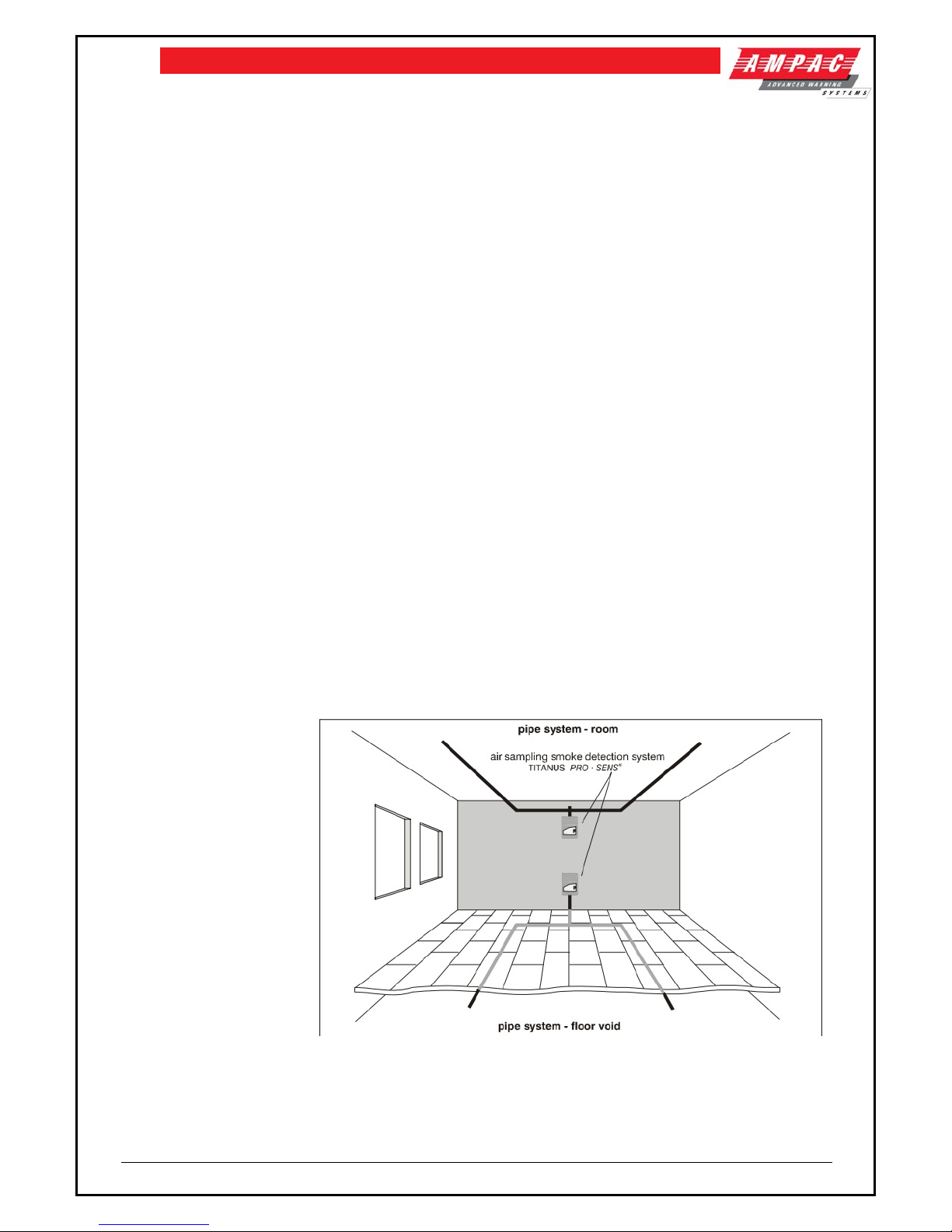

6 Installation Pipe System ........................................................................................................ 97

6.1 Linear expansion of the pipe system ......................................................................... 100

6.2 Patented air sampling points...................................................................................... 102

6.3 Ceiling lead through ................................................................................................... 104

6.4 Monitoring in forced air flow systems (ventilation or climatic applications)............... 106

6.4.1 Detection at air inlets/outlets.......................................................................... 106

6.4.2 Detection in bypass systems ......................................................................... 106

6.5 Filter ........................................................................................................................... 107

6.5.1 Installation of the air Filter type LF-AD-x ....................................................... 107

6.5.2 Mounting of the special filter type SF-400/650 .............................................. 108

6.6 Air return .................................................................................................................... 109

6.7 Noise suppressor ....................................................................................................... 110

6.8 3-Way ball valve......................................................................................................... 111

6.9 Steam trap.................................................................................................................. 113

6.10 Detonation prevention device .................................................................................... 114

6.11 Test adapter............................................................................................................... 116

7 Commissioning..................................................................................................................... 117

7.1 Air flow sensor adjustment......................................................................................... 118

7.1.1 Adjustment independent of the air pressure.................................................. 119

7.1.2 Adjustment dependent on the air pressure.................................................... 120

7.2 Detector module and alarm transmission .................................................................. 121

7.3 Check air flow monitoring........................................................................................... 122

7.4 Check fault signal transmission ................................................................................. 123

7.5 Operational check of TITANUS PRO·SENS®............................................................ 124

7.5.1 Preparations for operational check ................................................................ 124

7.5.2 Operational check .......................................................................................... 125

8 Maintenance .......................................................................................................................... 127

8.1 Visual Check .............................................................................................................. 127

8.2 Flash Code Table....................................................................................................... 127

8.3 Checking dector module and alarm transmission...................................................... 128

8.4 Checking the pipe system.......................................................................................... 128

8.5 Exchange of detector module .................................................................................... 129

8.6 Changing the air filter LF-AD -x ................................................................................. 130

8.7 Changing special air filter SF-400/650....................................................................... 131

8.8 Check of the air flow sensor adjustment.................................................................... 132