TABLE OF CONTENTS

1 SAFETY AND OTHER WARNINGS........................................................................................................6

1.1 Safe Use of Equipment....................................................................................................................6

2 RECEIVING AND STORAGE..................................................................................................................7

2.1 Receiving.........................................................................................................................................7

2.2 Inspection.........................................................................................................................................7

2.3 Storage after Delivery......................................................................................................................7

2.4 Unpacking of Equipment..................................................................................................................7

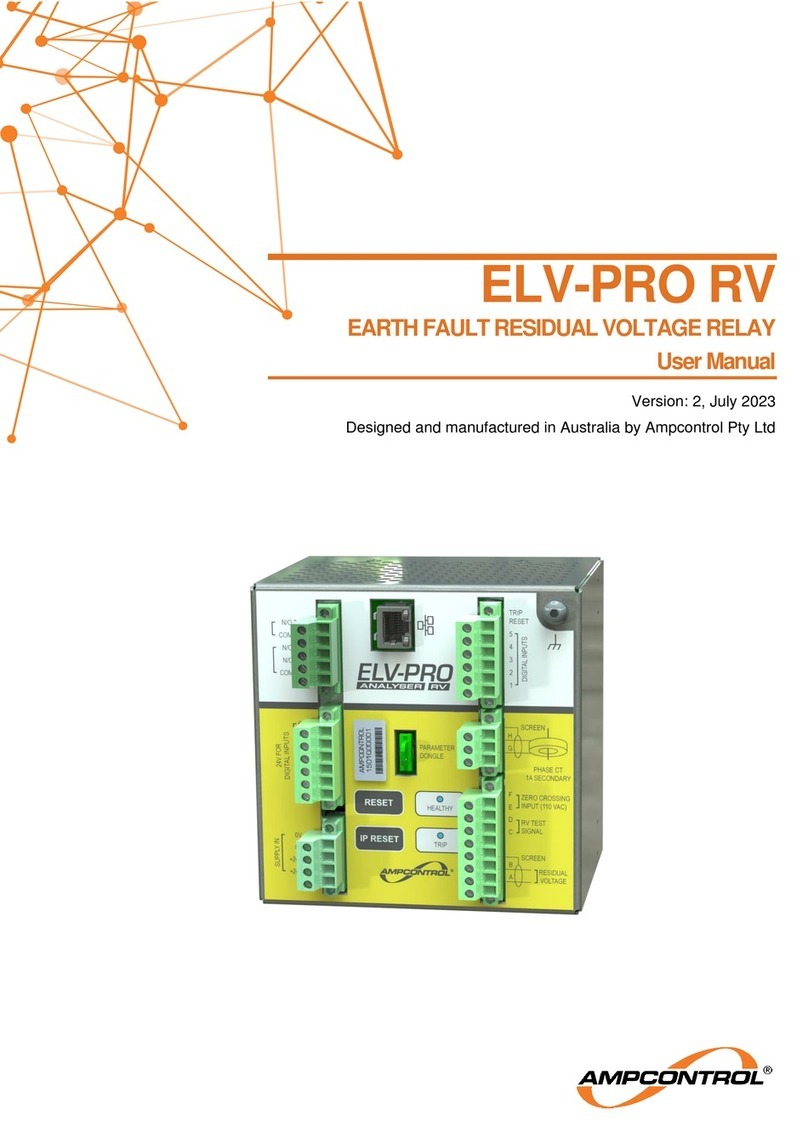

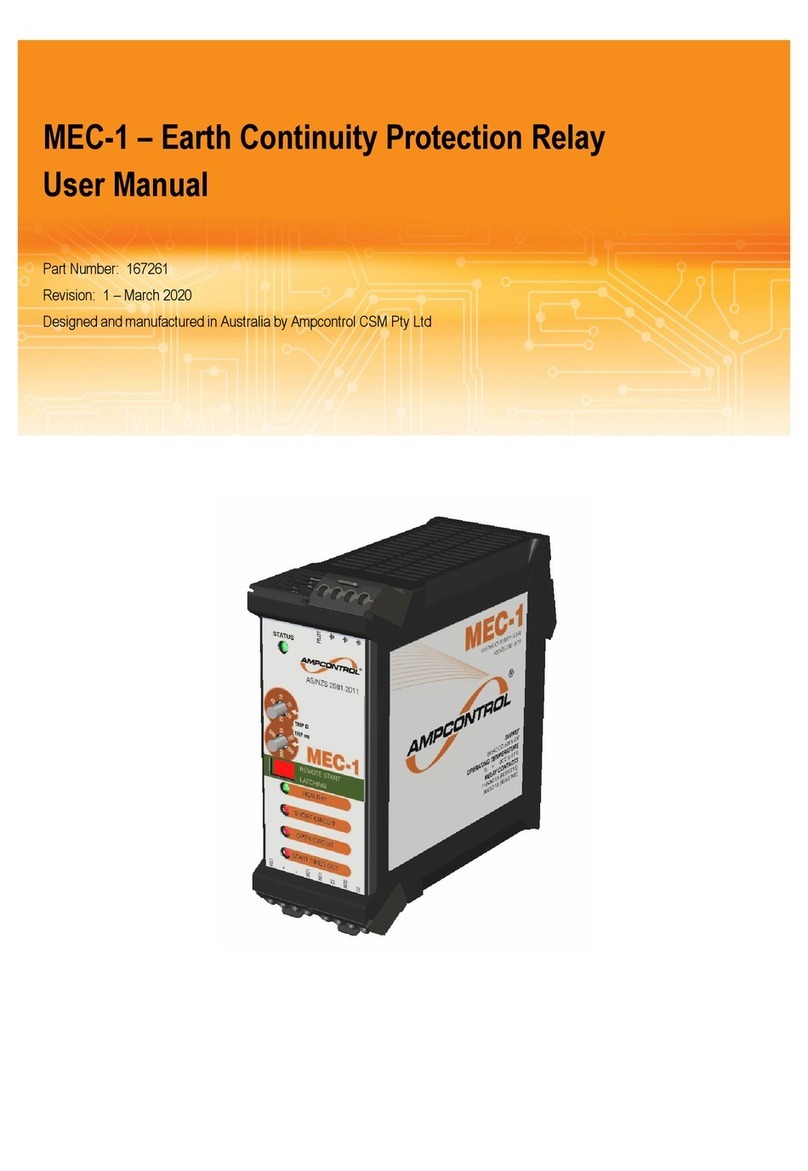

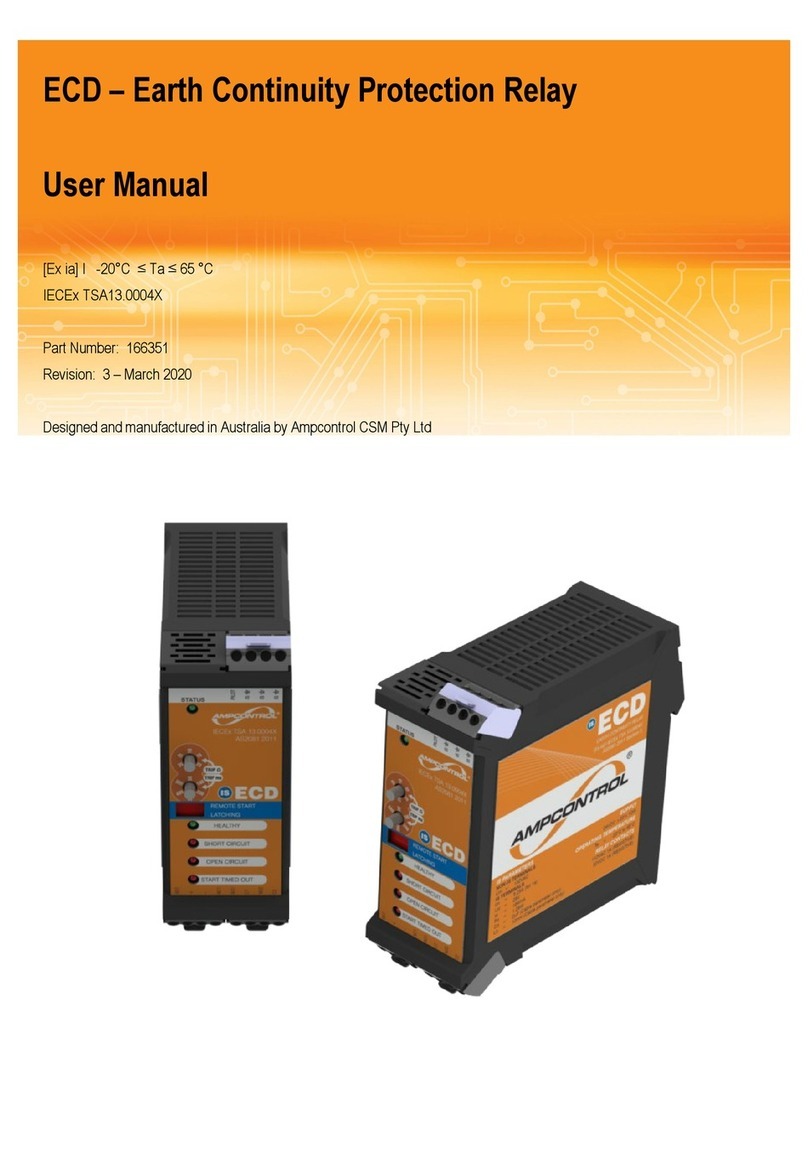

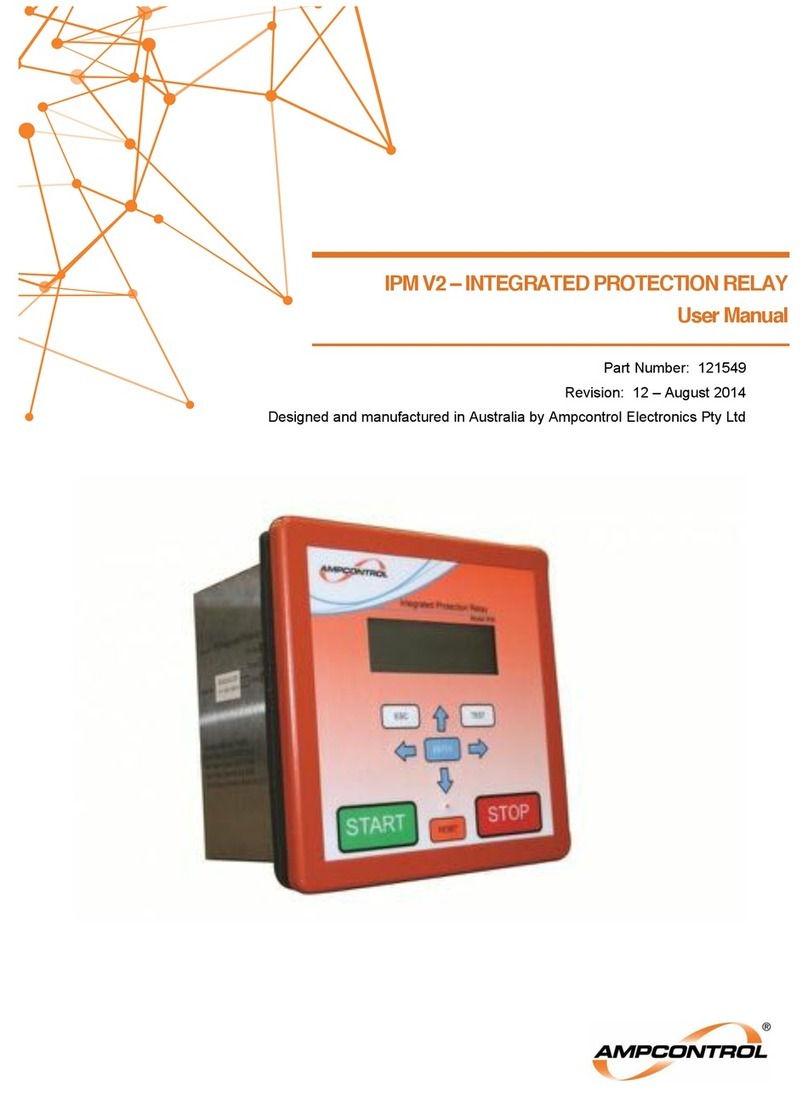

3 PRODUCT OVERVIEW ..........................................................................................................................8

3.1 ELM V2 Earth Leakage Relay..........................................................................................................8

3.2 Accessories....................................................................................................................................10

4 INSTALLATION.....................................................................................................................................12

4.1 General Warnings..........................................................................................................................12

4.2 Mandatory Installation Practices....................................................................................................12

4.3 ELM V2 Relay Mechanical Installation Information........................................................................13

4.4 Toroid Mechanical Installation Information ....................................................................................14

4.5 Electrical Installation Information ...................................................................................................16

5 COMMISSIONING AND CALIBRATION...............................................................................................18

5.1 Earth Leakage Test........................................................................................................................18

6 PRODUCT OPERATION.......................................................................................................................19

6.1 Configuration of Trip Level and Trip Time......................................................................................19

6.2 Resetting the ELM V2 Relay..........................................................................................................20

6.3 ELM V2 Indicators..........................................................................................................................20

6.4 CT Fault Protection........................................................................................................................20

6.5 Fail Safe Operation........................................................................................................................21

7 SERVICE, MAINTENANCE & DISPOSAL ............................................................................................22

7.1 Equipment Service.........................................................................................................................22

7.2 Equipment Maintenance ................................................................................................................23

7.3 Disposal.........................................................................................................................................23

8 SPECIFICATIONS.................................................................................................................................24

9 SETTINGS QUICK REFERENCE GUIDE.............................................................................................24

10 EQUIPMENT LIST...............................................................................................................................25

10.1 Relay............................................................................................................................................25

10.2 Toroids.........................................................................................................................................25

10.3 Accessories..................................................................................................................................25

APPENDIX A: EARTH LEAKAGE PROTECTION REQUIREMENTS......................................................26

A1 Australian Standards for Earth Leakage (Mining Industry).............................................................26