ELM USER MANUAL ISSUE 4

-4-

3. ELM Earth Leakage Relay

3.1 Description

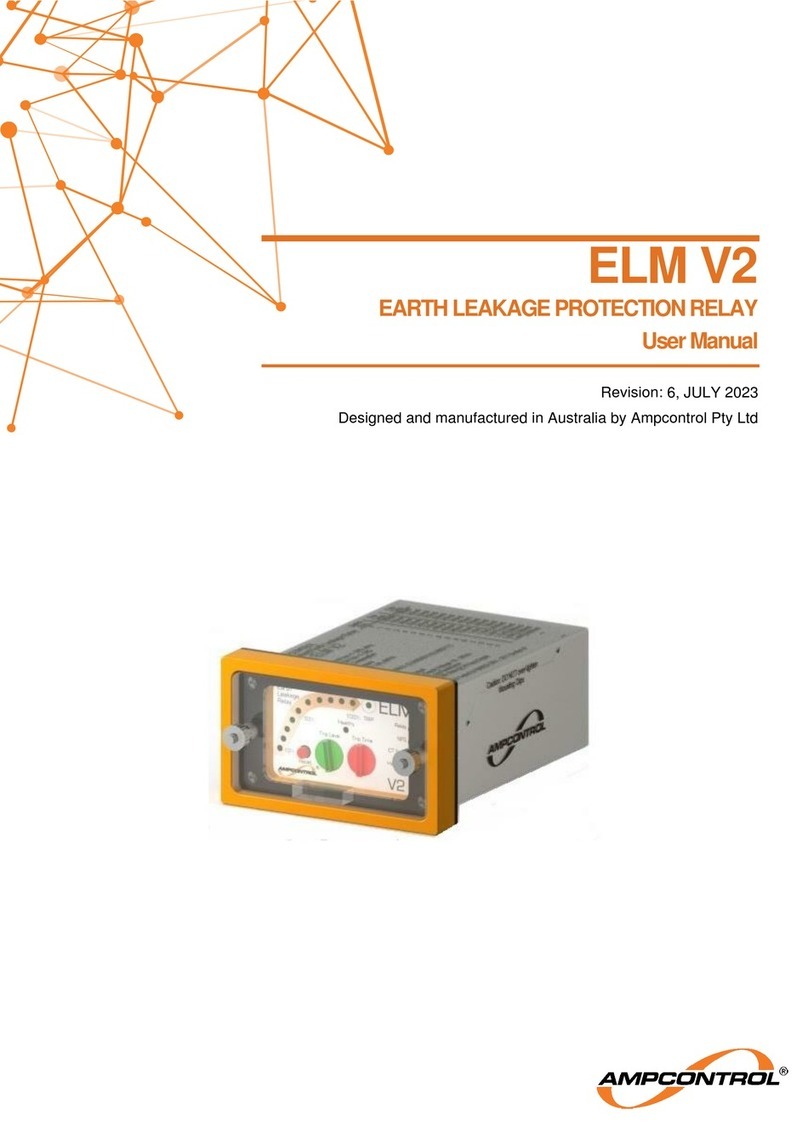

The Ampcontrol ELM Earth Leakage Relay is

electronic in design and is based on

microprocessor technology. The 'Healthy' LED

flashes to indicate correct operation of the

microprocessor. The Relay uses a toroid to

measure earth fault current. A definite time

operating characteristic is provided with

adjustable trip sensitivity and time delay.

When a fault occurs and the trip level and time

delay is exceeded the relay’s trip function is

activated, operating the trip contacts connected

in the system control circuit. The 'Trip' LED is

'On' when a trip occurs. The trip condition is

latched in non-volatile memory and requires

operation of the reset input to clear the trip

condition. An internal reset is also provided on

the facia of the relay. The 'Relay' LED is 'On'

to indicate the relay is energised.

A ten-segment LED bar graph indicates the %

of leakage level being detected. This reading

can be remotely monitored/displayed using the

4-20mA Output of the Relay. When the relay

measures currents with frequencies much

greater than 50Hz the bar graph LED fast

flashes (5Hz) instead of being steady. Should

the high frequency current persist until the

time delay is exceeded the relay will trip. The

'Har.Trip' LED (Harmonic Trip) is 'On' when a

trip occurs.

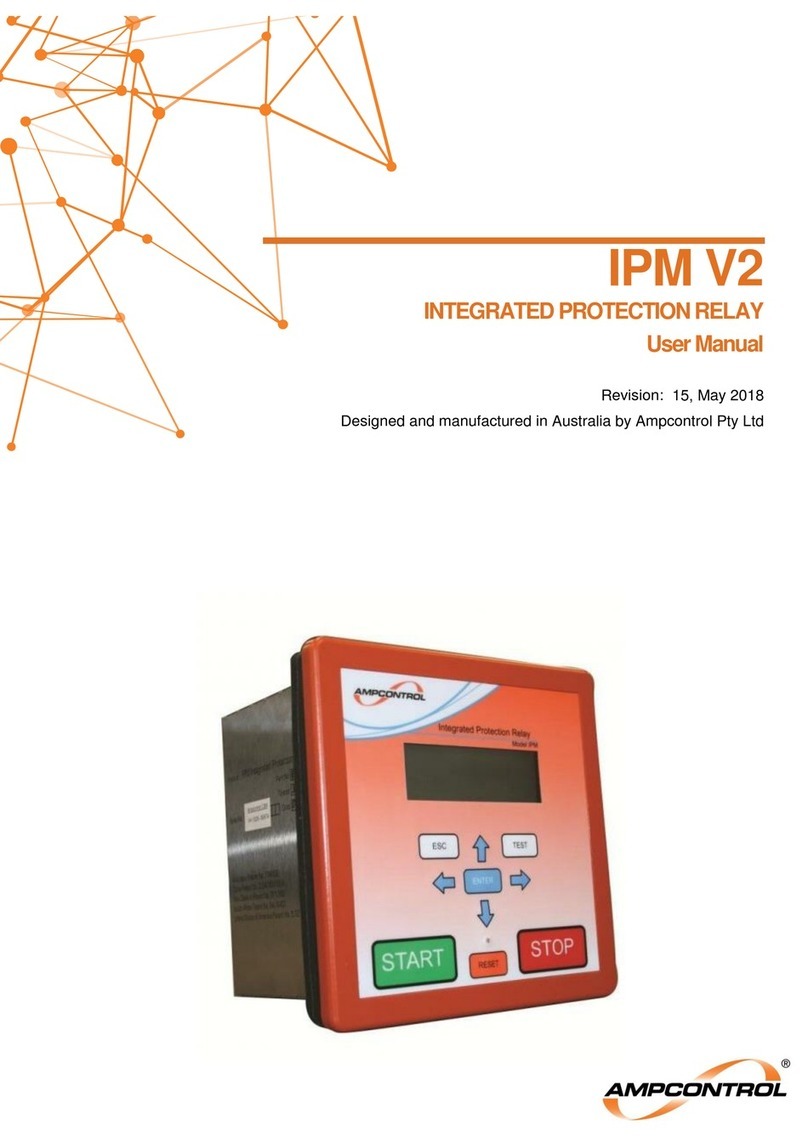

The ELM Earth Leakage Relay is housed in a

stainless steel case and can be either ‘DIN

Rail’ mounted or ‘Panel Mounted’ through a

69 x 39mm cut out. When panel mounted the

front of the ELM Relay is designed to provide

IP-56 ingress protection. There is provision to

prevent unauthorised adjustment of the trip

settings by sealing the post (in front of the

knurled nut) with a lead seal, thus preventing

the removal of the front facia cover.

An internal switch mode power supply allows

the ELM to operate from 24VAC to 132VAC

or 20VDC to 185VDC.

The ELM Relay has been designed and tested

for use on fault-limited systems. To ensure

maximum protection the earth leakage system

should be used in conjunction with the other

protection systems covered by AS2081. The

collective systems are designed to limit touch

and step potentials.

The relay is also suitable for industry where

equipment or system earth leakage protection

is required. The relay is not suitable for

personal protection, which requires trip levels

of 20-30mA, with instantaneous operation.

(Refer AS3190).

The ELM Relay continually monitors the

toroid and if the connection is lost the relay

will trip and flash the ‘CT Fault LED’.

3.2 Methods of Earth Leakage Protection

The ELM Relay is suitable for the two

methods of protection used. They are the Core

Balance and Series Neutral earth leakage

protection systems. (See previous section for

details).

3.3 Testing Procedure

A test current is injected through the window

of the toroid to test the operation of the relay

(See typical connection diagram, Page 6). To

reset the relay press the button located on the

facia of the relay or provide an external

normally open contact (it is recommended that

a twisted pair be used between the N/O contact

and the reset input). The reset button is also

used to access the memory of the processor to

view the maximum level of leakage since the

previous trip. A section of the bar graph will

slow flash (2Hz) indicating the peak level

while, the reset button is held closed and will

continue to flash for 1 second after the reset

button is released.

3. 4 Toroids

The ELM Relay is designed for use with

Ampcontrol EL500S series Toroids. They are

available with window sizes 25, 60 & 85mm.

These allow trip settings from 100mA to 2.5A.

3.5 Mode of Operation

The relay can be operated in fail-safe or non-

fail safe modes of operation.

Fail Safe Mode:

This mode is the default and preferred

method, where the relay drops out on fault

or loss of power. Power to the relay is from

the line side of the isolating device or from

an independent supply.

Non Fail Safe Mode:

In this mode of operation the relay picks up

on fault. This method should only be used

when the supply to the relay is only

available from the load side of the isolating