5

Amphenol Network Solutions

All rights reserved. 12.05.19 145121-2 A0

509.926.6000 – amphenol-ns.com

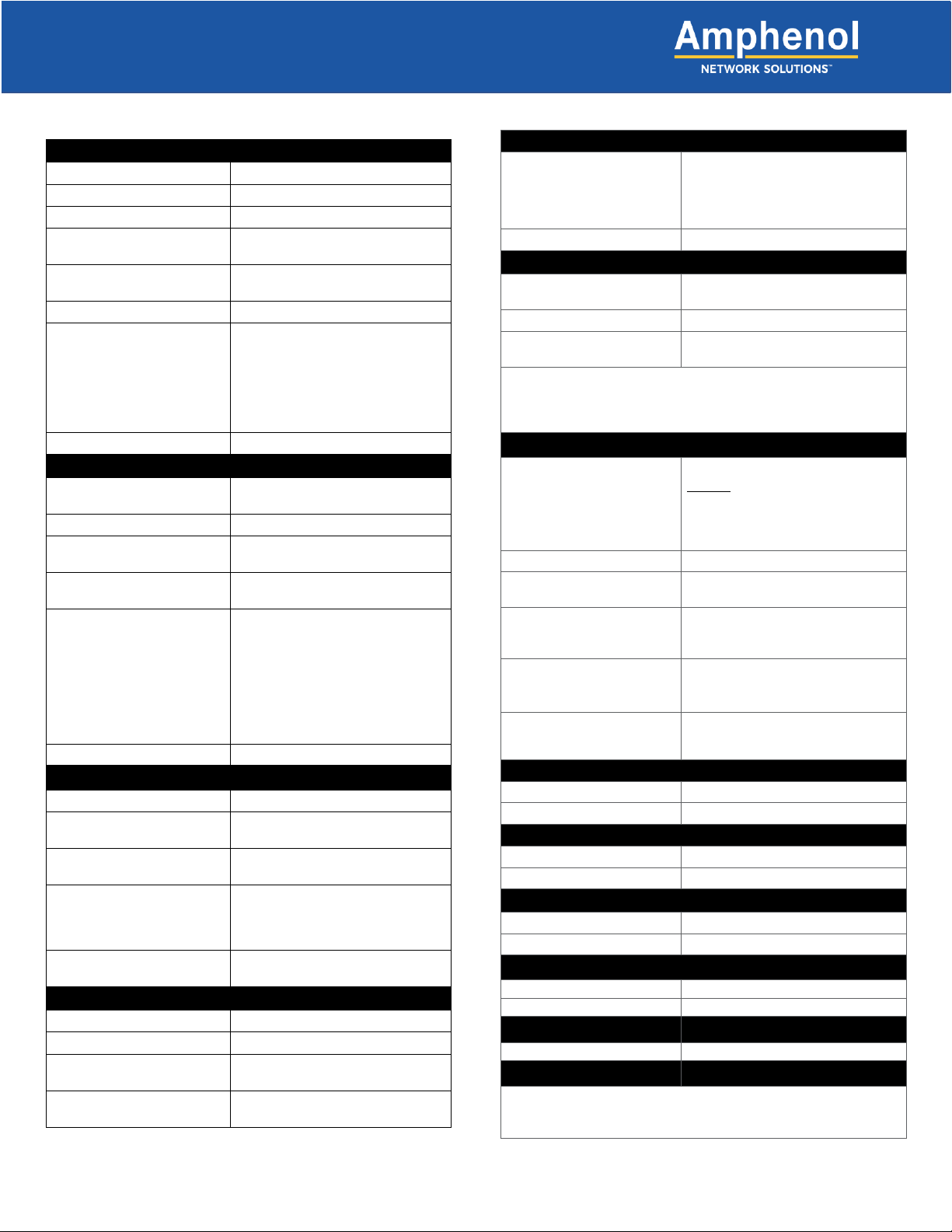

Specifications

Inputs

Voltage range, nominal voltage -40V to -60V (Nominal -48 VDC)

Max. input load rating 600A per side at max.

Short circuit withstand rating 5000A (breakers/fuses); 450A GMT

Nominal power loss at full load Less than 75W per side @ 28,000W

full load per side (600A x 48V)

Percentage of full power

dissipation at nominal voltage

Less than 1%

Max. input interrupt device 750A

Input terminal studs

(with nuts, flat washers and

spring washers) for dual-hole

compression lugs

• Two pair of 3/8 – 16 studs on 1

in. centers per terminal [max.

lug width of 1.94 in. (49.2 mm)]

per pair

• Torque nut (using 9/16 in. or 15 mm

wrench) to 150 in.-lb (~17 N•m),

max.

Input wire size #1 AWG to 750 MCM

Max. output single-pole, long-

delay circuit breaker (ea.)

100A

Max. output TPS or TLS 125A

Max. output load (ea.) -

continuous

100A

Minimum short circuit

interrupt rating

5000A

Output terminal studs (with

KEPS, nuts and washers)

for dual-hole compression

lugs

• 1/4 - 20 studs on 5/8 in. centers

[max. lug width of 0.680 in.

(15.8 mm) for a BATT terminal

and

0.70 in. (17.7 mm) for a RETURN

terminal].

• Torque bolts (using 7/16 in. or 12

mm wrench) to 50 in.-lb (~5.5

Output wire size #14 AWG minimum

GMT Outputs

Max. GMT output fuse (ea.) 20A

Max. GMT output load (ea.) -

continuous

14A

Minimum short circuit interrupt

rating

450A

GMT output terminals for

compression lugs

• 10 removable, #6-32 panhead

screws (max. lug width of 0.29 in.

[7.4 mm]).

• Torque to 6.3 in.lb (~0.7N•m), max.

GMT output wire size #22 AWG to #12 AWG, depending on

output fuse rating

Dry Contact Alarms

Alarm wire size #22 to #18 AWG

Alarm terminals Wire wrap

Relay contact ratings Dry Form-C contacts (1A @ 30 VDC,

0.5A @ 60 VDC, 0.3A @ 125 VAC)

Max. alarm power rating @24V: 72 mA (1.73W)

@48V: 147 mA (7.06W)

Grounding

Earth GND terminal bolts

(with washers) for dual-hole

compression lug

• Two pair of 1/4 - 20 threaded

holes on 5/8 in. centers.

• Torque bolts (using 7/16 in. or 12

mm wrench) to 50 in.-lb (5.5 N•m),

Ground wire size #2 AWG recommended

Voltage Sensor

Sensor accuracy 0 to -19.99V: ±0.3V

-20V to -60V: ±0.1V

Voltage measurement range 0 to -60 VDC

Feed voltage detection 0 to -19.99V: Alarm

-20V to -60V: Normal

NOTE:

• Voltage measurement may be slightly different than at input

terminal blocks due to the voltage drop within the panel.

• Sensors are factory calibrated and do not require user adjustment.

Communication

nrgNET sensor and alarm

card power

(via nrgNET cabling

connection to an

nrgCONTROL-BT controller)

-48 VDC nominal

*NOTE: The nrg600BT08-M chassis

MUST BE connected to an

nrgCONTROL-BT controller via

nrgNET cabling for LED Alarm

nrgNET data communication RS-485

nrgNET connector Removable 5-pin connector with

screw down terminals

nrgNET connector functions nrgNET IN from the nrgCONTROL or

nrgSMART Panel, nrgNET OUT to next

inline nrgSMART panel

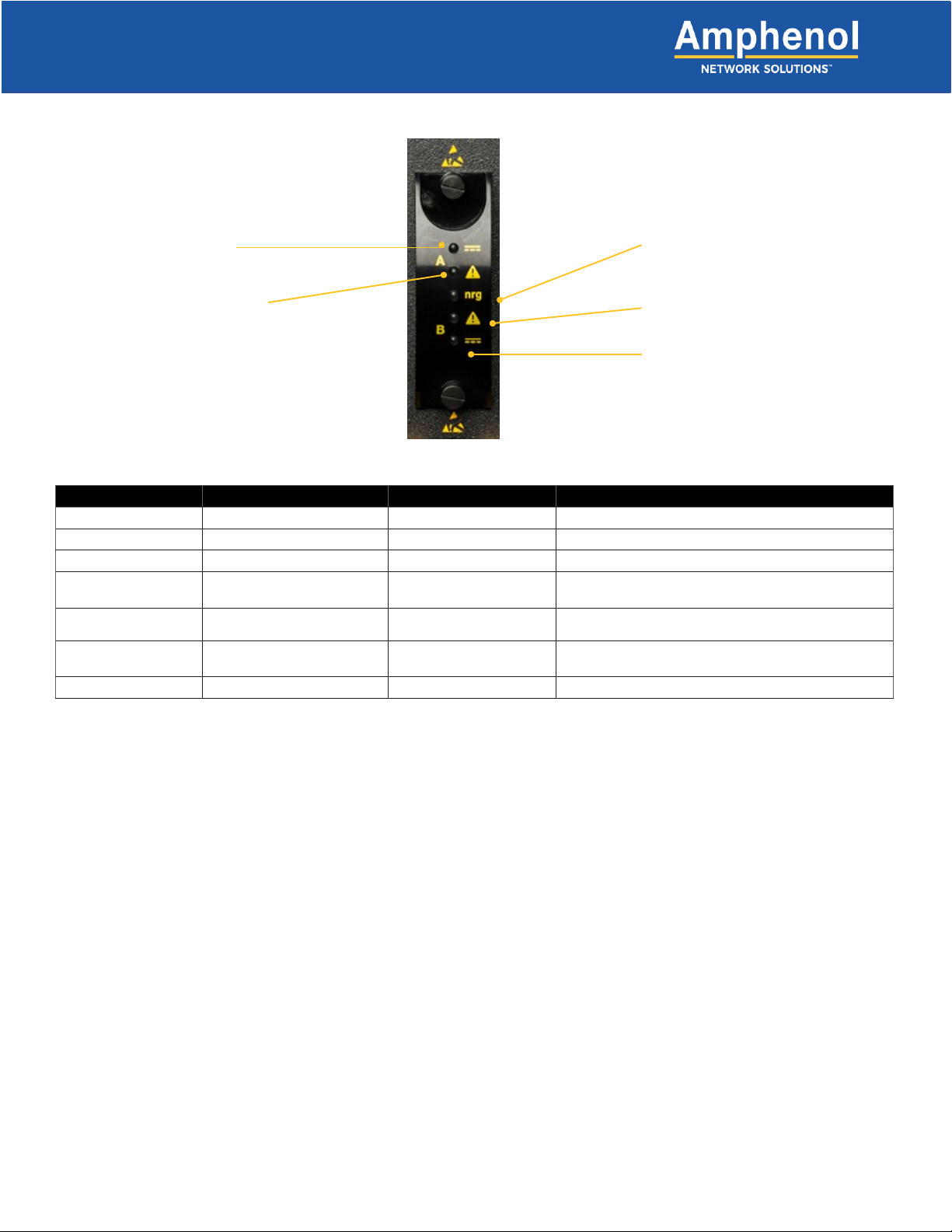

LED Alarm Indicators

(requires nrgNET & controller

for power)

A/B bus power

A/B fuse alarms

Supported protocols Proprietary nrgNET used to

communi- cate between panels and

Fit and Finish

Material 14-gauge steel

Color Pewter grey powder coat

Mechanical

Dimensions (L x W x H): 12” x 17.25” x 7”

Rack space 4RU

Environmental

Operating temperature -5° to +44°C

Humidity 0 to 90%, non-condensing

Weight (approximate)

Compliance

Warranty

Standard 1-year warranty on all parts.

The warranty is extended through the addition of the annual

maintenance and support contract (nrgSMART-APSC)