Bennett 621 PLUS Supplement

Bennett 1218 E. Pontaluna Road, Spring Lake, MI 49456

USA 800-235-7618 ~ Outside USA 231-798-1310

sales@bennettpump.com ~ www.bennettpump.com

BENNETT 621 PLUS INTERCONNECTION BOX

(GENERIC CURRENT LOOP FUEL INTERFACE)

INCLUDES INSTRUCTIONS FOR THE INSTALLATION OF 1 TO 24 FUEL POSITIONS AND SERVICING THE 621 PLUS

INTERCONNECTION BOX.

P/N 115590 621 Interconnection Circuit Board

P/N 104080 Fan Out Circuit Board

P/N 114036 RS232 Port Circuit Board

Installation & Service Manual

141841 Rev A 11/19/20

Only Trained Personnel May Work on This Equipment

READ THIS MANUAL

This manual has important information for safe installation and operation of this equipment. Read and understand this manual

before applying power. Keep this manual and tell all service personnel to read this manual. If you do not follow the instructions,

you can cause bodily injury, death, or damage to the equipment.

Bennett 1218 E. Pontaluna Road, Spring Lake, MI 49456

USA 800-235-7618 ~ Outside USA 231-798-1310

sales@bennettpump.com ~ www.bennettpump.com

The material included in this installation manual is accurate at the date of publication. The intent of this manual is

to assist. If further assistance is required, please contact the Bennett Technical Service Department at 1-800-423-

6638.

Bennett Marketing Services can be contacted by mail, facsimile, telephone or e-mail at the locations specified

below:

Bennett Pump Company

Marketing Services

1218 East Pontaluna Road

Spring Lake, MI 49456

Telephone from USA 1-800-235-7618

Telephone from outside USA 231-798-1310, Extension 287 or 269

Customer Service USA 231-719-6050; Facsimile USA 231-799-6202

Website: www.bennettpump.com

For new manuals, visit our web page at www.bennettpump.com

IMPORTANT

Examine the shipment immediately upon arrival to make certain there has been no damage or loss in transit.

Bennett Pump Company, as shipper, is not liable for the hazards of transportation. Please make damage claims

directly to the truck line.

NOTICE: This device complies with part 15 of the FCC rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interface, and (2) this device must accept interference received, including

interference that may cause undesired operation

.

Revision

Date

Description

A

4/15/20

Original Document

Bennett 621 Plus Interconnection Box Instruction & Service Manual Table of Contents

i

TABLE OF CONTENTS

TABLE OF CONTENTS I

SECTION 1: SAFETY INFORMATION 1

General Information.......................................................................................................................................................................................................2

Hazardous locations ......................................................................................................................................................................................................2

Codes and Standards ....................................................................................................................................................................................................2

Unauthorized Alteration of Bennett Products....................................................................................................................................................2

Abbreviations and Acronyms.....................................................................................................................................................................................2

SECTION 2: PRODUCT INTRODUCTION 3

Specifications....................................................................................................................................................................................................................3

621 Plus Interconnection Box Configurations ....................................................................................................................................................3

621 Plus Interconnection Box - Recommended Equipment and Materials ...........................................................................................3

AC Power Requirements ..............................................................................................................................................................................................3

Hardware Connections .................................................................................................................................................................................................4

Pump Controller Assembly 621 Box .......................................................................................................................................................................4

SECTION 3: INSTALLATION INSTRUCTIONS 5

Step 1 - Remove Enclosure Cover ...........................................................................................................................................................................5

Step 2 - Remove desired Knockouts from Enclosure ......................................................................................................................................5

Step 3 - How To Mount the 621 Plus Interconnection Box ..........................................................................................................................6

Step 4 -Instructions for Earth Grounding the Equipment..............................................................................................................................6

Step 5 - AC Power Wiring ...........................................................................................................................................................................................7

Step 6 - Connect Dispenser Fuel Communication Wires...............................................................................................................................7

Step 7 - Connect Data Distribution Box Communication Wires.................................................................................................................8

Step 8 - Connect RS485 Communication Wires ................................................................................................................................................9

Step 9 - How to Start-Up the 621 Interconnection Box.................................................................................................................................9

SECTION 4: SERVICE INSTRUCTIONS 11

621 Circuit Board Assembly..................................................................................................................................................................................... 11

Fan-Out Circuit Board................................................................................................................................................................................................ 14

RS232 Port Circuit Board Assembly ..................................................................................................................................................................... 16

SECTION 5: PARTS 17

How To Place an Order for Parts........................................................................................................................................................................... 17

Parts List........................................................................................................................................................................................................................... 17

SECTION 6: WIRING DIAGRAMS 19

621 Interconnection Board –Generic Current Loop..................................................................................................................................... 19

Station Interconnection Diagram.......................................................................................................................................................................... 20

APPENDIX A –HELPFUL PROGRAMMING HINTS 21

Bennett Pacific Programming................................................................................................................................................................................. 21

Nucleus Programming............................................................................................................................................................................................... 21

Bennett 621 Plus Interconnection Box Instruction & Service Manual Table of Contents

ii

Page Intentionally Left Blank

Bennett 621 Plus Interconnection Box Instruction & Service Manual Safety Information

1

SECTION 1: SAFETY INFORMATION

For safe installation of this equipment, read and understand all dangers, warnings, and cautionary information. Save this safety

information in a readily accessible location. Look for the following warnings throughout the manual:

Red and White “DANGER” means: If you do not follow the instructions, severe injury or death will occur.

Orange and Black “WARNING” means: If you do not follow the instructions, severe injury or death can occur.

Yellow and Black “CAUTION” means: If you do not follow the instructions, damage can occur to the dispenser.

Blue and White “IMPORTANT” means: Helpful tips and other recommendations on equipment installation, usage, and

maintenance should be observed.

DANGER PELIGRO DANGER

GASOLINE AND FUEL ETHANOL IS FLAMMABLE. NO SMOKING OR OPEN FLAME.

DISCONNECT ALL POWER TO THIS EQUIPMENT BEFORE INSTALLATION, SERVICE, OR ANY MAINTENANCE.

WARNING ADVERTENCIA MISE EN GARDE

You must have training in the installation, service, or maintenance of this equipment (dispenser, pump, console,

control box, or submerged pump) before working on it. Maintenance repairs must be done by authorized

personnel only. Warranty work may only be performed by Bennett certified technicians.

To prevent electric shock, keep the electrical parts of the dispenser dry.

Electronic components are static sensitive. Use only proper static precautions (e.g. static straps) before working

on the equipment.

You must have training in the operation and programming of this dispenser before using it. READ THE

OPERATORS MANUAL.

Make sure this equipment is correctly grounded. Failure to do will cause injury or damage equipment or improper

operation. Improper grounding voids the warranty. Ground resistance must be 1 ohm or less.

All dispenser AC Power circuits (for remotes only) must be on the same phase or damage will occur to the

dispenser CPU or the sub-pump relay box.

Make sure that all labels, decals, warning, cautions, and instructions are fastened to the equipment. Order

replacement labels from Bennett.

CAUTION PRECAUCIÓN MISE EN GARDE

Do not drill holes in fuel dispensers. Holes can cause failure of the electronic equipment. THE WARRANTY WILL

BECOME VOID. Use only adhesive backed sign mounting brackets.

Sharp edges may be present after removing knockouts. Use cut resistant gloves to prevent injury.

All communication wires must be 18AWG or larger, gas and oil resistant stranded copper, THHN per National

Electrical Code.

Do not daisy chain communication data wires. Damage to the control console may occur.

Do not use wire nuts. Splicing with wire nuts can cause communication failure, system failure, and may void

warranty.

IMPORTANT IMPORTANTE IMPORTANT

All trained technicians must work in accordance to all requirements, standards, and guidelines specified by the

suppliers Environmental Standards® Health, Safety, Security & Environment (HSSE) policies. Note: Bennett Pump

highly recommends all technicians observe HSSE policies defined by the supplier. Bennett Pump does not impose

any restrictions or additional requirements contained in Environmental Standards® Health, Safety, Security &

Environment (HSSE) policies.

!! READ AND UNDERSTAND ALL WARNING LABELS ATTACHED TO THE DISPENSER !!

Bennett 621 Plus Interconnection Box Instruction & Service Manual Safety Information

2

GENERAL INFORMATION

Read this manual carefully and read all tags/labels attached to the 621 Plus Interconnection Box before starting any maintenance and/or service. A

controller that is not properly maintained will not perform properly and will void the Bennett limited warranty.

Before installation, operation, maintenance and/or service ensure that protection against lighting strikes are in accordance with the American

Petroleum Institute Recommended Practice RP 2003, Protection Against Ignitions Arising out of Static, Lightening, and Stray Currents.

Service of the Bennett products and all accessories (e.g. Nozzles, Hoses, and Breakaways) must be performed by a technician who is trained in

accordance to all codes, standards, and regulations.

HAZARDOUS LOCATIONS

For safe operation, ensure that the dispenser is in a classified area as detailed below per NFPA 30, Flammable and Combustible Liquids Code and

NFPA 70, National Electric Code. For further information on the classification of locations for Fuel Dispensers, see NFPA 30, Flammable and

Combustible Liquids Code.

CODES AND STANDARDS

Follow all local, state, and federal requirements for installation of all equipment.

API 2003 –Protection Against Ignitions Arising Out of Stray, Lightning, and Stray Currents

NFPA 30 –Flammable and Combustible Liquids Standard

NFPA 30A –Motor Fuel Dispensing Facilities Standard

NFPA 70 –National Electric Code

International Fire Code –2000 Edition

UNAUTHORIZED ALTERATION OF BENNETT PRODUCTS

DANGER: BEFORE PERFORMING ANY TYPE OF SERVICE TO THE DISPENSERS, BE SURE TO SHUT OFF ALL ELECTRICAL SUPPLIES AND

SECURE THEM IN THE OFF POSITION. CLOSE ALL VALVES IN INCOMING PIPING. MAINTENANCE MUST BE PERFORMED

BY TRAINED PERSONAL ONLY.

Bennett Pump Company products are designed to meet or exceed the standards of Underwriters Laboratories, Inc., Federal Communication

commission, and National Institute of Standards and Technology. Compliance with these standards protects the operator and the consumer from

personal injury and ensure an accurate delivery of product. Any deviation from the use of authorized replacement parts or alteration of a designed

product configuration may cause personal injury, death or the revocation of one or all of the above approvals.

Bennett Pump Company will not assume responsibility or liability for any consequential injury or damage caused by the unauthorized alteration of

its products.

ABBREVIATIONS AND ACRONYMS

TERM

DESCRIPTION

AC

Alternating Current

API

America Petroleum Institute

ASR

Automatic Statistical Reconciliation

DC

Direct Current

DCR

Debit Credit Reader

EPA

Environmental Protection Agency

GCL

Generic Current Loop

Hz

Hertz

NEC

National Electrical Code

NFPA

National Fire Protection Agency

NPT

National Pipe Taper or National Pipe Thread

NREL

National Renewable Energy Laboratory

OEM

Original Equipment Manufacturer

POS

Point-of-Sale

PEI

Petroleum Equipment Institute

PVC

Polyvinyl Chloride

RAM

Random Access Memory

RFI

Radio Frequency Interference

THHN

Thermoplastic High Heat-resistant Nylon-coated

UL

Underwriters Laboratories, Inc.

VAC

Voltage Alternating Current

VDC

Voltage Direct Current

VOM

Volt-Ohm Meter

Bennett 621 Plus Interconnection Box Instruction & Service Manual Product Introduction

3

SECTION 2: PRODUCT INTRODUCTION

The Bennett Model 621 Plus Interconnection Box is an interface device for third party point-of-sale systems. It allows the customer to use Bennett

Fuel Dispensing equipment with Consoles supporting the Generic Current Loop Fuel protocol.

SPECIFICATIONS

621 Dimensions (length x width x height).................................................................................................12in x 12in x 4in (30.5cm x 30.5cm x 10.2 cm)

Fan-Out Circuit Board Dimensions (length x width) ......................................................................................................................................8.5in x 3.4in

Operang Temperature......................................................................................................................................................0C to +40C / +32F to +104F

Storage Temperature.........................................................................................................................................................-20C to +65C / -4F to +149F

Operang Humidity ..................................................................................................................................................................0 to 95% Non-Condensing

Storage Humidity .................................................................................................................................................................30% to 70% Non-Condensing

AC Power Input Voltage...................................................................................................................................................................120/240VAC 50/60Hz

Fuse Amperage ............................................................................................................................................................................................... 1.0 A / 0.5A

Protocols (Fuel Only)........................................................................................................................................................................Generic Current Loop

621 PLUS INTERCONNECTION BOX CONFIGURATIONS

Fuel Only

Fuel and DCR with use of POS hardware supporting the Generic Current Loop protocol.

621 PLUS INTERCONNECTION BOX - RECOMMENDED EQUIPMENT AND MATERIALS

The items listed below are recommended for proper installation of the Bennett 621 Interconnection Box. Note: Consult the control console and/or

point-of-sale manufacturer for component requirements.

P/N 115763 –621 Pump Controller

P/N 141188 Power Supply Cable (included)

Dispenser Communication Wires - 18 AWG or larger gas and oil resistant (customer supplied)

Jumpers

Voltmeter

Tool to remove knockouts

Personal Protection Equipment

AC POWER REQUIREMENTS

Each 621 Plus Interconnection Box uses one 120V, 50/60 Hz, or 240V, 50/60 Hz circuit for power. Make sure the power source has the correct

frequency and voltage. Only one dispenser electronics Hot and Neutral needs to be pulled per dispenser. Note: A 12-gauge green ground wire must

be installed to the lug provided in the box.

WARNING: ALL DISPENSER AC POWER CIRCUITS (FOR REMOTES ONLY) MUST BE ON THE SAME PHASE OR DAMAGE WILL OCCUR TO

THE DISPENSER CPU OR THE SUB-PUMP RELAY BOX.

1. The 621 Plus Interconnection Box must be connected to a dedicated AC receptacle.

2. AC voltage must be a minimum of 100VAC or a maximum of 240VAC ~ 50/60Hz.

AC POWER SUPPLY CABLE

(P/N 141188)

AC RECEPTACLE

Bennett 621 Plus Interconnection Box Instruction & Service Manual Product Introduction

4

HARDWARE CONNECTIONS

PUMP CONTROLLER ASSEMBLY 621 BOX

The 621 Interconnection Box is used to interface with third party point-of-sale systems and supports the Generic Current Loop Fuel protocol.

ITEM

DESCRIPTION

1

Enclosure

2

Circuit Board Assembly RS232 Port Board

3

Circuit Board Assembly Fan Out Board

4

Circuit Board Assembly 621 Generic

Current Loop Adaptor

5

Grounding Lug

N/A

Front Cover (Not Shown)

N/A

AC Power Module (Not Shown)

2

1

4

5

3

Data Distribution Box

BENNETT 621 PLUS INTERCONNECTION BOX

Dispenser

Generic Current Loop

(Up to 24 Fueling Points)

AC Power Module

Fuel Communication

Incoming 12 VDC

Fan-Out Board

Interconnection Box

RS485 Data

RS485 Data

RS232 Port Board

Bennett 621 Plus Interconnection Box Instruction & Service Manual Installation Instructions

5

SECTION 3: INSTALLATION INSTRUCTIONS

Bennett Pump Dispensers are to be installed by trained technicians. All technicians must be aware of ALL safety instructions. If you are not a

Bennett trained technician, please contact Bennett Technical Support at 1-800-423-6638 for training information.

Identifying the features of the unit prior to installation will provide an understanding of how to perform an accurate installation. Follow the steps

below to install a 621 Interconnection Box.

STEP 1 - REMOVE ENCLOSURE COVER

Remove the enclosure cover and set aside. Retain screws for reuse. Note: After installation is complete, replace cover using the screws provided.

STEP 2 - REMOVE DESIRED KNOCKOUTS FROM ENCLOSURE

CAUTION: SHARP EDGES MAY BE PRESENT AFTER REMOVING KNOCKOUTS. USE CUT RESISTANT GLOVES TO PREVENT INJURY.

Several knockouts are located around the enclosure for accessibility. Select a knockout sized to fit the desired connector, wire, cable, etc. and

carefully remove. Try not to damage the enclosure when removing knockouts... Next, insert the connector from the outside of the enclosure. BE

CAREFUL of sharp edges.

Bennett 621 Interconnection Box Instruction & Service Manual Installation Instructions

6

STEP 3 - HOW TO MOUNT THE 621 PLUS INTERCONNECTION BOX

The 621 Plus Interconnection Box measures 12” x 12” x 4”. The enclosure requires four mounting screws. These four screws are on 10 ½” by 10 ½”

centers.

Note: When installing a 621 Interconnection Box pay attention to the locations of the AC Receptacle.

1. Layout screws on wall 10 ½” by 10 ½” centers and slide enclosure’s 4 keyhole mounting slots over screws and tighten.

2. Slide enclosure’s four keyhole-mounting slots over screws and tighten.

STEP 4 -INSTRUCTIONS FOR EARTH GROUNDING THE EQUIPMENT

WARNING: FAILURE TO PROPERLY GROUND THE EQUIPMENT CAN CAUSE INJURY OR DAMAGE TO THE EQUIPMENT AND WILL VOID

THE BENNETT LIMITED WARRANTY.

IMPORTANT: Follow proper grounding procedures to reduce radio frequency interference (RFI). All Bennett equipment must be properly

grounded. Follow National Electrical Code, Article 514-7 for grounding requirements as well as Bennett’s grounding

procedures. It is UNACCEPTABLE to rely on the conduit for these grounding requirements.

Grounding provides a path of least resistance for electric current to reduce the risk of electric shock. Grounding is also required to protect the

dispenser’s computer from external electrical noise generating devices. The ground wire connection must provide 1 ohm (or less) resistance to

earth ground.

To establish a good earth ground, follow this procedure:

1. Connect a 12-gauge (minimum), green stranded wire to the green ground screw inside the enclosure. Connect the other end to the Chassis.

Note: This wire must be connected for proper operation to occur.

MOUNTING HOLES

MOUNTING HOLES

GROUND SCREW

GROUND WIRE

Bennett 621 Interconnection Box Instruction & Service Manual Installation Instructions

7

STEP 5 - AC POWER WIRING

WARNING: MAKE SURE THE 621 INTERCONNECTION BOX IS PROPERLY GROUNDED WITH 12AWG GREEN EARTH GROUND WIRE IS

CONNECTED TO THE GREEN GROUND SCREW INSIDE THE ENCLOSURE. FAILURE TO PROPERLY GROUND THE

EQUIPMENT CAN CAUSE INJURY OR DAMAGE TO THE EQUIPMENT AND WILL VOID THE BENNETT LIMITED WARRANTY.

1. Connect the 12V AC Power Module (141188) to [J3]on the RS232 Port Circuit Board. Make sure locking connectors are secure.

2. Connect the other end into a dedicated AC receptacle.

STEP 6 - CONNECT DISPENSER FUEL COMMUNICATION WIRES

CAUTION: All communication wires must be 18 AWG or larger gas and oil resistant stranded copper THHN per National Electrical

Code.

CAUTION: Do not daisy chain communication data wires. Damage to the control console may occur.

CAUTION: DO NOT use wire nuts. Splicing with wire nuts can cause communication failure, system failure, and may void

warranty.

Dispenser Fuel communication wires for fueling positions 1 through 24 terminate directly to the 621 Circuit Board. Each fueling point has a positive

(orange) and negative (yellow) connection. A Fueling Point is one side of a dispenser. A two-sided dispenser would have two fueling points. Each

fueling position is labeled on the circuit board as shown in the figure below. Fueling points 1 through 16 are labeled as 1 through 8. Fueling points

17 through 24 are labeld as 9-12. (e.g. Fueling point 1 & 2 are labeled as 1, fueling point 3 & 4 are labeled as 2).

1. Connect data wires to terminal strip position 1-12. Note: Each terminal strip channel will supply two fueling positions. This will allow a

maximum of 24 fueling points.

2. Connect the other end of the data wire to the 708 CPU Board or to the Current Loop Personality Module located on the 819/919 CPU Board.

Refer to the 621 Plus Wiring Diagram (P6056) for detailed information.

Continued on the next page…

FUEL POSITION 17 & 18 (-) YELLOW

FUEL POSITION 17 & 18 (+) ORANGE

FUEL POSITION 19 & 20 (-) YELLOW

FUEL POSITION 19 & 20 (+) ORANGE

FUEL POSITION 23 & 24 (-) YELLOW

FUEL POSITION 23 & 24 (+) ORANGE

FUEL POSITION 21 & 22 (-) YELLOW

FUEL POSITION 21 & 22 (+) ORANGE

FUEL POSITION 1 & 2 (-) YELLOW

FUEL POSITION 1 & 2 (+) ORANGE

FUEL POSITION 3 & 4 (-) YELLOW

FUEL POSITION 3 & 4 (+) ORANGE

FUEL POSITION 5 & 6 (-) YELLOW

FUEL POSITION 5 & 6 (+) ORANGE

FUEL POSITION 7 & 8 (-) YELLOW

FUEL POSITION 7 & 8 (+) ORANGE

FUEL POSITION 9 & 10 (-) YELLOW

FUEL POSITION 9 & 10 (+) ORANGE

FUEL POSITION 11 & 12 (-) YELLOW

FUEL POSITION 11 & 12 (+) ORANGE

FUEL POSITION 13 & 14 (-) YELLOW

FUEL POSITION 13 & 14 (+) ORANGE

FUEL POSITION 15 & 16 (-) YELLOW

FUEL POSITION 15 & 16 (+) ORANGE

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

J3

Bennett 621 Interconnection Box Instruction & Service Manual Installation Instructions

8

3. Connect a DB9 (DE-9) cable the [J1] connector on the RS232 Port Board for fuel communication. Connect the other end to the Point of Sale.

STEP 7 - CONNECT DATA DISTRIBUTION BOX COMMUNICATION WIRES

WARNING: DO NOT DAISY CHAIN COMMUNICATION DATA WIRES. DAMAGE TO THE CONTROL CONSOLE MAY OCCUR.

The following description is used to connect a Data Distribution Box via Generic Current Loop communication. Field connections will depend on the

generic current loop equipment available at the site. Note: For any other POS that communicates using Bennett protocol must be programmed on

Channel 1. Refer to the 621 Plus Wiring Diagram (P6056) for detailed information.

1. Connect 1 x 18ga. Orange (+ positive) wire to the 621 CPU Board at TS1, + positive as indicated on the diagram. Connect the other end to the

Data Distribution Box.

2. Connect 1 x 18ga. Yellow (- negative) wire to the 621 CPU Board at TS1, - negative as indicated on the diagram. Connect the other end to the

Data Distribution Box.

(-) YELLOW TO DATA DISTRIBUTION CABINET

(+) ORANGE TO DATA DISTRIBUTION CABINET

J1

Bennett 621 Interconnection Box Instruction & Service Manual Installation Instructions

9

STEP 8 - CONNECT RS485 COMMUNICATION WIRES

The following description is used for a RS485 payment communication. Field connections will depend on the Generic Current Loop Equipment

Available at the Site. Please read and understand other manufacturer information prior to installation. Refer to the 621 Wiring Diagram (P2915) for

detailed information.

Note: RS-485 wires should be twisted together no less than 3 turns per foot to reduce the effects of electrical noise on the

communication circuit. Due to the risk of noise, causing possible problems with communication, Bennett highly recommends

the use of twisted wires, but does not require it. Note: Belden shielded cable is accepted but the “drain” must not be

terminated.

1. Connect 1 x 18ga. (+ positive) wire to the Fan Out Board at TS1, (+) positive as indicated on the diagram. Connect the other end to the 819/919

CPU Board at TS3, Terminal 1.

2. Connect 1 x 18ga. (- negative) wire to the Fan Out Board at TS3, (-) negative as indicated on the diagram. Connect the other end to the

819/919 CPU Board at TS3, Terminal 3.

STEP 9 - HOW TO START-UP THE 621 INTERCONNECTION BOX

If a problem occurs, refer to the service instructions or call Bennett Technical Support at 1-800-423-6638. See Appendix A - Helpful Programming

Hints or refer your dispenser operators’ manual for detailed programming instructions.

1. Apply power to dispensers, program them for operation, and address the fueling positions accordingly.

2. Apply power to POS, Site Controller, and Data Distribution Cabinet. Program and initialize POS as required.

3. Verify that the communication LED’s are flashing rapidly on the 621 board.Refer to page 13 for LED diagnostics and troubleshooting

information.

(-) NEGATIVE

RETURN

(+) POSITIVE

Bennett 621 Interconnection Box Instruction & Service Manual Installation Instructions

10

Page Intentionally Left Blank

Bennett 621 Plus Interconnection Box Instruction & Service Manual Service Instructions

11

SECTION 4: SERVICE INSTRUCTIONS

The following section provides a detailed description of the connections to the terminal strips, pinouts LED’s, and jumpers on

the 621 Circuit Board, RS232 Port Board, and Fan Out Circuit Board. The service information in this manual is intended for

Bennett trained and licensed technicians. All technician must be aware of all safety instructions provided on page 1. If you are

not a Bennett trained technician, Please contact Bennett Technical Support at 1-800-423-6638 for training information.

621 CIRCUIT BOARD ASSEMBLY

For locations with 1 through 16 Fueling Points.

CONNECTOR DESCRIPTIONS

The following is a description of the connections, LED’s, and jumpers located on the 621 circuit board.

J1 AC LINE VOLTAGE INPUT

The AC Power Module is used to provide AC power to the RS232 Port Board at the J2 connector. Only one dispenser electronics

Hot and Neutral needs to be pulled per dispenser.

Each 621 Interconnection Box uses one 120V, 50/60 Hz, or 240V, 50/60 Hz circuit for power. Make sure the power source has

the correct frequency and voltage

JP1 CURRENT LOOP VOLTAGE

The JP1 is a 3-pin jumper used for current loop voltage. The center two pins MUST be set for operation in the field. Note:

Failure to set jumper in the center position will result in improper operation of the 621 board.

5 1

6 2

J1

AC Line Voltage Input

JP1

Current Loop Voltage

TS1

Data Communication

JP2

Run or Program Mode

TS6-TS9

Fueling Points 9-16

TS2-TS5

Fueling Points 1-8

Bennett 621 Interconnection Box Instruction & Service Manual Service Instructions

12

JP2 RUN MODE OR PROGRAM MODE

The JP2 is a 3-pin jumper used to select run mode for field operation or program mode for flash programming (BENNETT USE

ONLY).

Run Mode - This mode MUST be used for operation in the field.

Program Mode - This mode is exclusively used for flash programming at Bennett Pump Company. DO NOT CHANGE THIS

SETTING! The board will not operate correctly if the jumper is in this position. NOT FOR FIELD USE!

Pin Description

1 & 2 (top) Run Mode –Field Use Only

2 & 3 (bottom) Program Mode–Bennett Use Only

TS1 POS COMMUNICATION

Terminal strip TS1 connects to the data distribution cabinet. There is a (+) positive and (–) negative connection.

Pin Description

1 (orange) (+) Positive

2 (yellow) (-) Negative

TS2 - TS5 (POSITIONS 1-8) DISPENSER COMMUNICATION

Terminal blocks TS2 through TS5 are labeled as (Positions 1 - 8) that are used for Fueling Points 1 through 16. Each terminal

strip position will supply two fueling points one (+) positive and one (–) negative connection. Note: A fueling point is one side of

a dispenser and a two-sided dispenser would have two fueling points.

TS6 - TS7 (POSITIONS 9-12) DISPENSER COMMUNICATION

Terminal block TS6 - TS7 (Positions 9-12) are used for Fueling Points 17 through 24. Each terminal strip position will supply two

fueling positions one (+) positive and one (–) negative connection. Note: A fueling point is one side of a dispenser and a two-

sided dispenser would have two fueling points.

TERMINAL POSITION

FUELING POINT

COLOR

PIN

9

17 & 18

Orange

(+) positive

17 & 18

Yellow

(-) negative

10

19 & 20

Orange

(+) positive

19 & 20

Yellow

(-) negative

11

21 & 22

Orange

(+) positive

21 & 22

Yellow

(-) negative

12

23 & 24

Orange

(+) positive

23 & 24

Yellow

(-) negative

13

NOT USED

Orange

(+) positive

NOT USED

Yellow

(-) negative

14

NOT USED

Orange

(+) positive

NOT USED

Yellow

(-) negative

15

NOT USED

Orange

(+) positive

NOT USED

Yellow

(-) negative

16

NOT USED

Orange

(+) positive

NOT USED

Yellow

(-) negative

TERMINAL POSITION

FUELING POINT

COLOR

DESCRIPTION

1

1 & 2

Orange

(+) positive

1 & 2

Yellow

(-) negative

2

3 & 4

Orange

(+) positive

3 & 4

Yellow

(-) negative

3

5 & 6

Orange

(+) positive

5 & 6

Yellow

(-) negative

4

7 & 8

Orange

(+) positive

7 & 8

Yellow

(-) negative

5

9 & 10

Orange

(+) positive

9 & 10

Yellow

(-) negative

6

11 & 12

Orange

(+) positive

11 & 12

Yellow

(-) negative

7

13 & 14

Orange

(+) positive

13 & 14

Yellow

(-) negative

8

15 & 16

Orange

(+) positive

15 & 16

Yellow

(-) negative

OR

(+ Positive)

(- Negative)

Bennett 621 Interconnection Box Instruction & Service Manual Service Instructions

13

LEDs DISPENSER & POS COMMUNICATION

The 621 Circuit Board has surface mount LEDs that are used for troubleshooting. If the console and dispensers are

communicating, all LED’s will be flashing. If not communicating with the POS or Dispenser then the “Transmit” LED will be on

constantly and the “Receive” LED will be off. Refer to the troubleshooting section for more information.

LED DIAGNOSTICS

The 621 Circuit Board has surface mount LEDs that are used for troubleshooting. If the console and dispensers are

communicating, all LED’s will be flashing. If not communicating with the POS or Dispenser then the “Transmit” LED for that side

will be on constantly and the “Receive” LED will be off. Refer to the troubleshooting section for more information. Refer to the

figure below for LED locations. Refer to the figure below for LED locations.

LED

COLOR

DESCRIPTION

COMMUNICATION TYPE

IMAGE

D1 (WT)

Red

Generic Current Loop Transmit

Fuel Controller

D2 (WR)

Red

Generic Current Loop Receive

Fuel Controller

D3 (BT)

Red

Bennett Transmit

Dispenser Communication

D4 (BR)

Red

Bennett Receive

Dispenser Communication

LED TROUBLESHOOTING

Remember to use the LED lights as diagnostic tools. Verify that the console is programmed correctly for operation with Bennett

dispensers.

FUEL CONTROLLER COMMUNICATION

LED

FUNCTION

D1 (WT)

POS GCL Transmit

D2 (WR)

POS GCL Receive

DISPENSER COMMUNICATION

LED

FUNCTION

D3 (BT)

Bennett Transmit

D4 (BR)

Bennett Receive

PROBLEM

CAUSES

SOLUTIONS

No LEDs are flashing

1. The 621 Board is not receiving power.

2. The console is not transmitting commands to

dispensers.

1. Ensure AC/DC power supply is

plugged in.

2. Ensure console is on and

programmed correctly.

Only D1 (WT) LED is flashing

1. Jumper JP2 is not in the RUN position.

2. The 621 Board is damaged.

1. Ensure JP2 is on the top two pins.

2. Replace the 621 Board.

D3 (BT) LED is momentarily

solid and D1 (WT) and D4

(BR) LEDs are flashing

1. Console is attempting to communicate with a

disconnected fueling position or dispenser

that is powered off.

1. Reconnect data wires or restore

power to the dispenser.

D1 (WT)

D2 (WR)

D3 (BT)

D4 (BR)

Bennett 621 Interconnection Box Instruction & Service Manual Service Instructions

14

FAN-OUT CIRCUIT BOARD

The Fan-Out Circuit Board in the Bennett Interconnect Box provides a connection to the dispenser’s payment module. The Fan-

Out Circuit Board has three sets of 10-position screw terminal strips.

TS1 connects the DATA (+) Positive for each dispenser.

TS2 connects the DATA Return for each dispenser. (If Required by Interface)

TS3 connects the DATA (-) Negative for each dispenser.

The board also provides switches for diagnostic purposes. Note: All switches must be in the ON position. If one of the switches

is in the OFF position the point-of-sale will not be able to communicate to the dispenser connected to that DATA loop.

The Debit/Credit Terminal’s connect to the Fan-Out Board. One bad card reader terminal has the potential to take down the

entire card system since they are all in a common parallel loop. The switches are used to remove a suspected "bad" terminal

from this data loop. Turning a switch off will actually remove two terminals (one dispenser) from the data loop. This should help

facilitate troubleshooting down to a particular dispenser.

TS3

Data (-) Negative

Switches 1 -8

TS1

Data (+) Positive

TS2

Data Return

Bennett 621 Interconnection Box Instruction & Service Manual Service Instructions

15

CONNECTOR DESCRIPTIONS

The following is a description of the connections and switches located on the Fan-Out Circuit board.

TS1 RS485 COMMUNICATION –DATA (+) POSITIVE

A 10-poition screw terminal strip provides a DATA (+) positive connection for each debit/credit terminal.

TS2 RS485 COMMUNICATION –GROUND

A 10-position screw terminal strip provides a GROUND connection for each debit/credit terminal.

TS3 RS485 COMMUNICATION –DATA (-) NEGATIVE

A 10-position screw terminal strip provides a DATA (-) negative connection for each debit/credit terminal.

S1-S8 SWITCH

Switches S1 - S8 on the circuit board are used for diagnostic purposes. Note: All switches must be in the ON position. If one of

the switches is in the OFF position the point-of-sale will not be able to communicate to the dispenser connected to that DATA

loop. All switches are turned OFF by default. Note: Switch not used on Pacific dispensers.

To turn a switch ON move the switch to the right.

To turn a switch OFF move the switch to the left.

SWITCH

DESCRIPTION

SETTING

1

Address 1

OFF / ON

2

Address 2

OFF / ON

3

Address 3

OFF / ON

4

Address 4

OFF / ON

5

Address 5

OFF / ON

6

Address 6

OFF / ON

7

Address 7

OFF / ON

8

Address 8

OFF / ON

Bennett 621 Interconnection Box Instruction & Service Manual Service Instructions

16

RS232 PORT CIRCUIT BOARD ASSEMBLY

The RS232 Port Circuit Board in the Bennett 621 Plus Interconnect Box receives AC Line Power, routes DC power to the 621

Circuit Board, provides an RS232 communication link to the 621 Circuit Board, and used for fuel control.

CONNECTOR DESCRIPTIONS

The following is a description of the terminal strips and pinouts used on the RS-485 Port Circuit Board.

J1 RS232 FUEL CONTROL

A D-Sub 9-pin connector serial communication interface port is dedicated to RS232 that is used to interface with the point of sale

for fuel control. A DB-9 (DE-9) cable is used to connect the point of sale for fuel control to the [J1] connector of RS232 Port Circuit

Board for fuel communication.

J2 DC POWER CONNECTION

The J2 connector is a 4-position connector that receives DC voltage from the 621 Circuit Board using wire assembly (p/n

141186).

Pin Description

1 Not Used

2 Not Used

3 +24V

4 Ground

J3 AC VOLTAGE INPUT

The J3 connector is a 4-position connector that is used to receive AC power from the AC Power Module Wire Assembly (p/n

141186). Note: Make sure the power source has the correct frequency and voltage.

Pin Description

1 Not Used

2 Not Used

3 +24V

4 Ground

TS1 POS COMMUNICATION (Generic Current Loop)

TS1 is a 2-position terminal strip used for generic current loop communication. Communication from the Point of Sale is

received from the Date Distribution Box using a 2-wire positive and negative connection.

Pin Description

1 (yellow) (-) negative

2 (orange) (+) positive

J2

621 Circuit Board Power

J3

AC Line Voltage Input

TS1

POS Communication

J1

Fuel Control

This manual suits for next models

3

Table of contents

Popular Circuit Breaker manuals by other brands

Siemens

Siemens VT630 operating instructions

Eaton

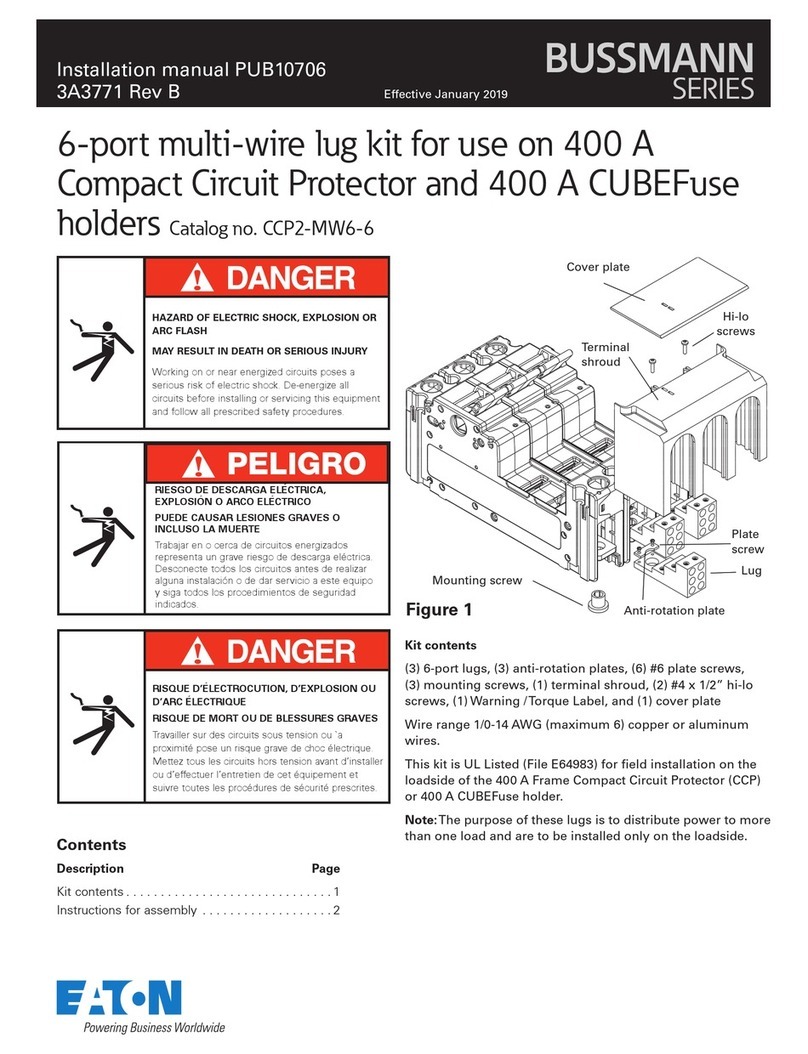

Eaton Bussmann Series installation manual

Leakomatic

Leakomatic M3i+ user manual

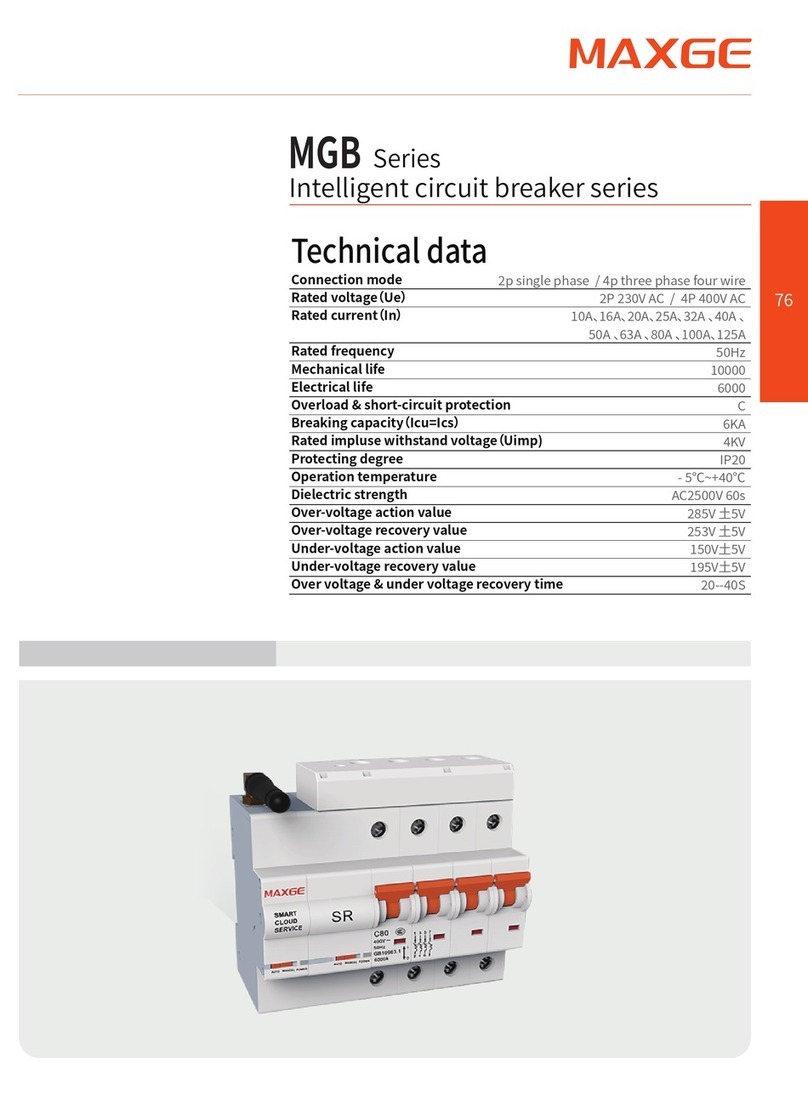

MAXGE

MAXGE MGB Series manual

Eaton

Eaton 36W-VAC25 Instructions for installation, operation and maintenance

LEGRAND

LEGRAND Pass & Seymour 1594-CMA Installation and operating instructions