Copyright2014AMPT,LLC5

TableofContents

InformationandDisclaimer.............................................................................................................3

ImportantSafetyInformation..........................................................................................................4

Warnings..............................................................................................................................................................4

Chapter1:Introduction...........................................................................................................7

GeneralDescription.........................................................................................................................7

Specifications...................................................................................................................................8

ModbusRegisterMap......................................................................................................................9

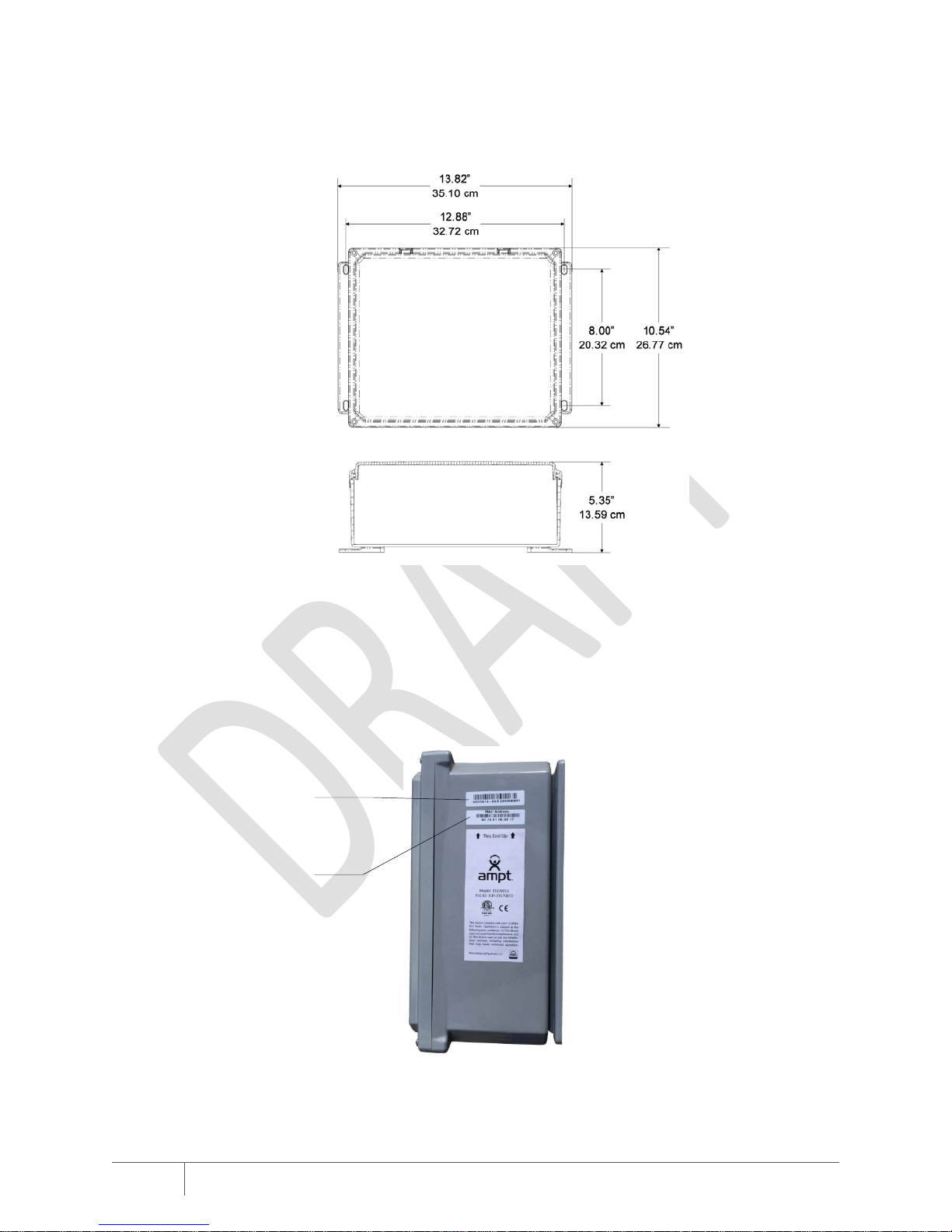

DimensionalDrawing.....................................................................................................................10

PhysicalOverview..........................................................................................................................10

Labels.................................................................................................................................................................10

Internal...............................................................................................................................................................11

UnderstandingtheStatusLEDs......................................................................................................12

Chapter2:InstallingtheAmpt‐CU........................................................................................13

InstallingtheEthernetCableFeed‐through....................................................................................14

MountingtheEnclosure.................................................................................................................16

ConnectingPoweroverEthernet...................................................................................................17

ConfiguringtheAmpt‐CUNetworkSettings...................................................................................18

RestoringFactoryDefaults.............................................................................................................19

Appendix...............................................................................................................................21

Compliance....................................................................................................................................21

FCCCompliance..................................................................................................................................................21