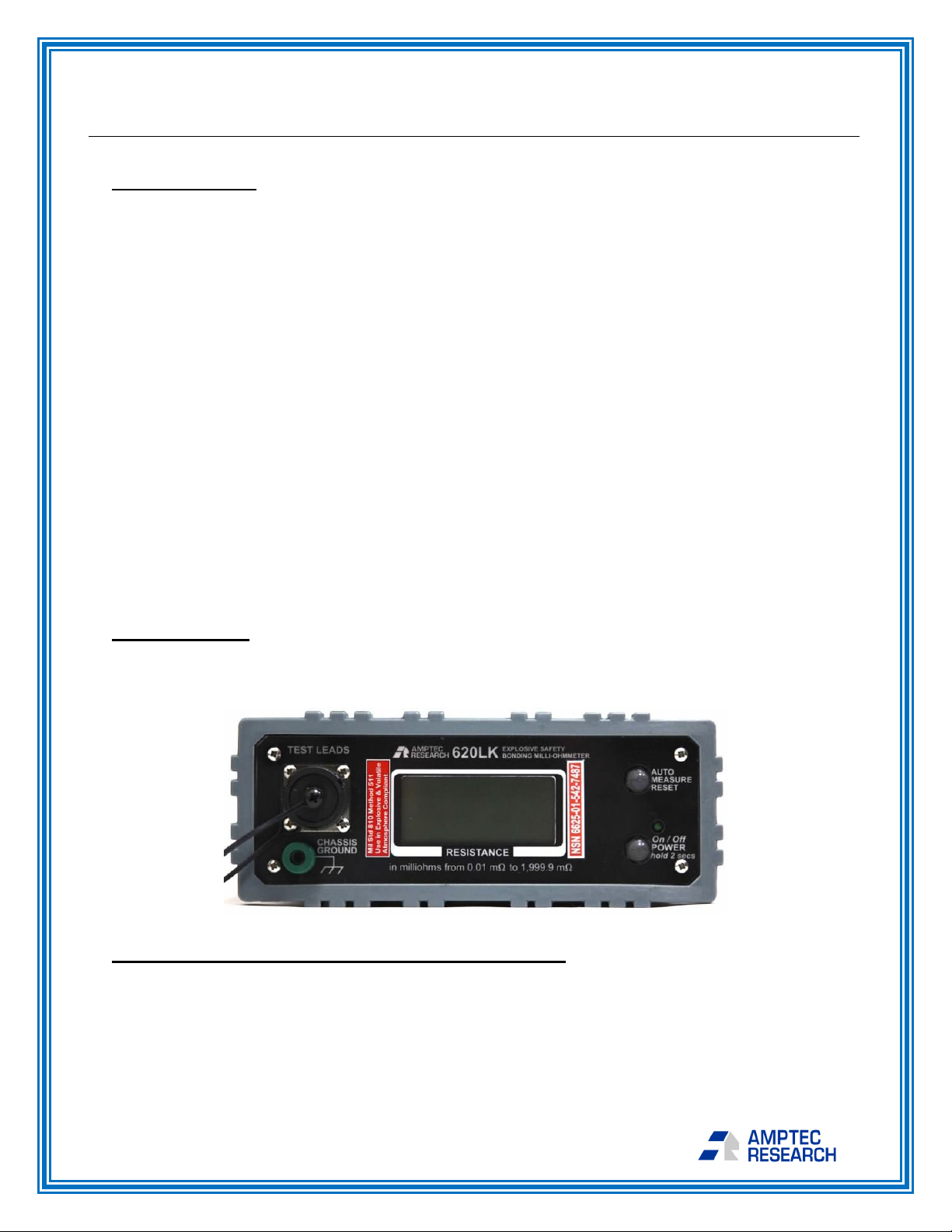

620LK Operation and Maintenance Manual – Rev. J – Updated January 2020

Page 8

13231 Rooster Springs Rd.

Austin, TX 78737

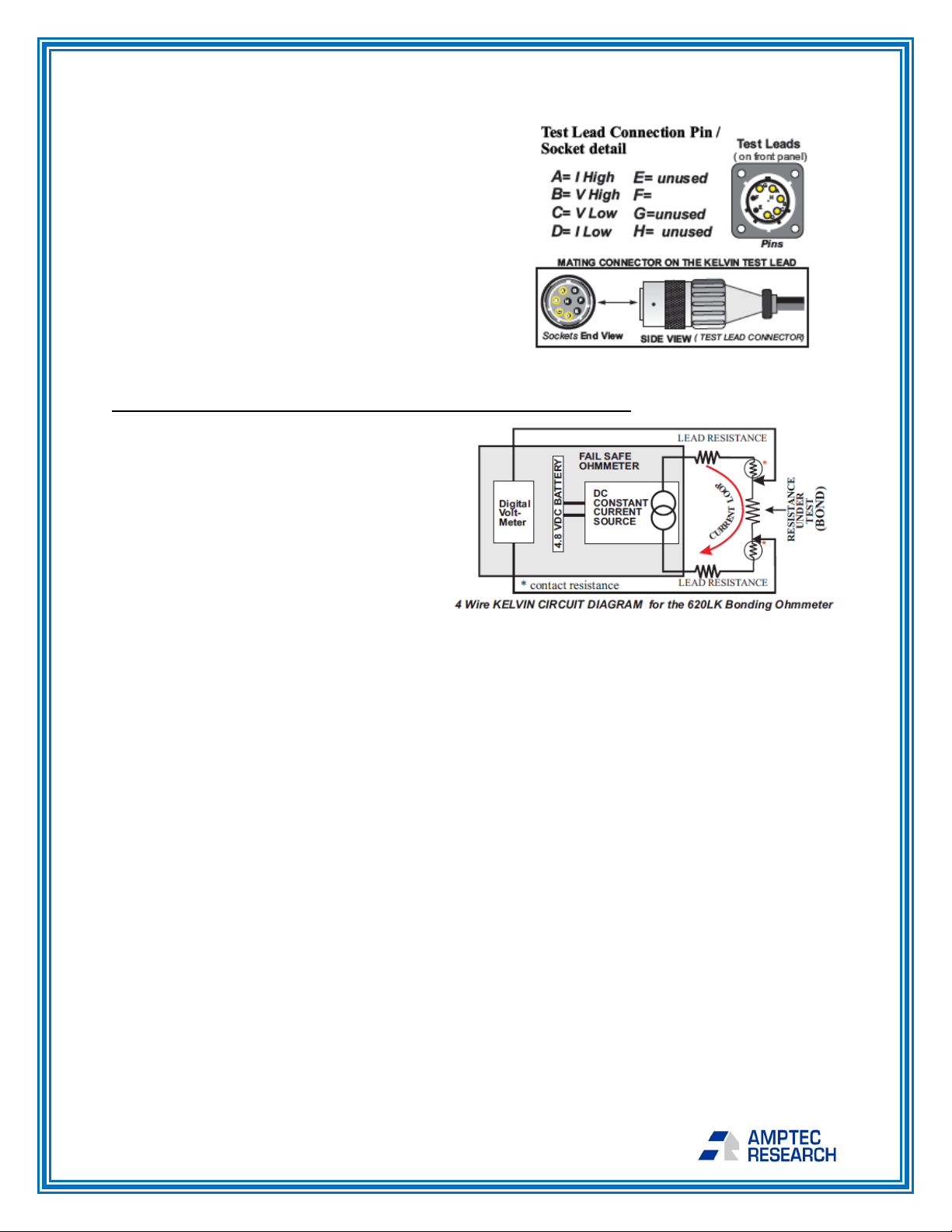

and “pin G” of the test lead connector (see

diagram on right). The unit’s chassis ground can

also be plugged into an earth ground connection

(for example, at the test site to preclude any static

voltages from building up, if desired). To prevent

damaging the gold pins and sockets, only use

AMPTEC test leads that are model 620LK

compatible. When using AMPTEC test leads or

probes, the notched connector end plugs directly

into the single access notched main connector.

Turn the connector collar clockwise until you feel

the click of the mating connector.

D-2.2 Alternate Connections and 4-Wire Kelvin Information

The AMPTEC 620LK meter is

compatible with most AMPTEC 630

series accessories. 620LK compatible

test lead/probes use a Trident

connector on the front panel as the

main connection for lead/probe sets.

The diagram on the right also provides

insight on how the 620LK operates.

The Trident connection provides the

same pin socket arrangement, 4-Wire

current high/low, and voltage sense high/low routed to the end of the leads, and the 4-

Wire Kelvin wires then terminate in a variety of configurations depending upon the

accessory. The 620LK keyed access connector also makes it virtually impossible during

normal operation to incorrectly connect lead/probe sets.

The 620LK meter measures DC resistance with a 4-Wire Kelvin, or 4 terminal ohms,

technique. Fundamentally, the 4-Wire Kelvin resistance method avoids measurement

errors induced from the resistance of the test lead/probes and the contact resistance of

the lead/probes to the device under test. Two of the wires, current high and current low,

pass through the bond resistance under test in a current loop as part of a constant

current source of 100 mA. It doesn’t matter if the current loop is longer or if there is

some contact resistance with the connection under test, because the constant current

source’s compliance voltage works to maintain 100 mA flowing in the loop. The other 2

wires, voltage high and voltage low, sense the voltage drop across the resistance under

test. The voltage measurement is high impedance. Meaning, virtually no current is

drawn in either voltage sense lead wire.

In conclusion, with 4-Wire Kelvin measurements, long distance test leads do not create

a measurement error as long as you have enough compliance voltage remaining in the

constant current loop. If test resistance is too high for the range, the meter will flash

“1 - - - -” and “>>>OR” to indicate the meter is over range.