SCALDING HAZARD.If the water temperature is

over 120°F., household members can suffer serious

or fatal scalding and painful and permanent injury.

• The Consumer Products Safety Commission recommends an initial

setting of 120°F., but advised that a slower response time of infants,

aged, disabled and other persons increases the scalding hazard and

may require lower settings.

• Always check the water temperature before use, including washing,

bathing or showering.

• Temperature limiting valves are available from your plumbing supplier. A

check valve must be installed in the boiler return line to prevent gravity

flow through the heat exchanger. This can cause overheating and result

in serious or fatal scalding.

SCALDING HAZARD. If the thermostat is not

working properly or if this product is not installed in

accordance with the manual, water temperature can reach excessive

levels that may cause serious or fatal scalding. After installation and any

servicing of the unit, verify that the thermostat is working and firmly

inserted in the thermostat well by following the thermostat testing

instructions in the manual.

Failure to use the correct replacement parts may

make your product unsafe.

In limited circumstances, space heating can be lost

in the home with unit utilizing priority mode. Any

demand for space heating is postponed until the water heater has

reached its set temperature. This delay in supplying the space heating

zones is usually not noticed by the inhabitants of the living spaces.

However, in the event of certain malfunctions such as circulator or

thermostat failure, space heating could be delayed indefinitely. If

undetected and uncorrected, freezing damage to piping could result.

If a steel hydropneumatic tank is in place, replace it

with a properly sized diaphragm expansion tank.

Otherwise, significant heat transfer problems can occur by causing air to

be trapped in the heat exchanger. If the boiler system has a diaphragm

expansion tank and the boiler temperatures are being changed, resize the

expansion tank.

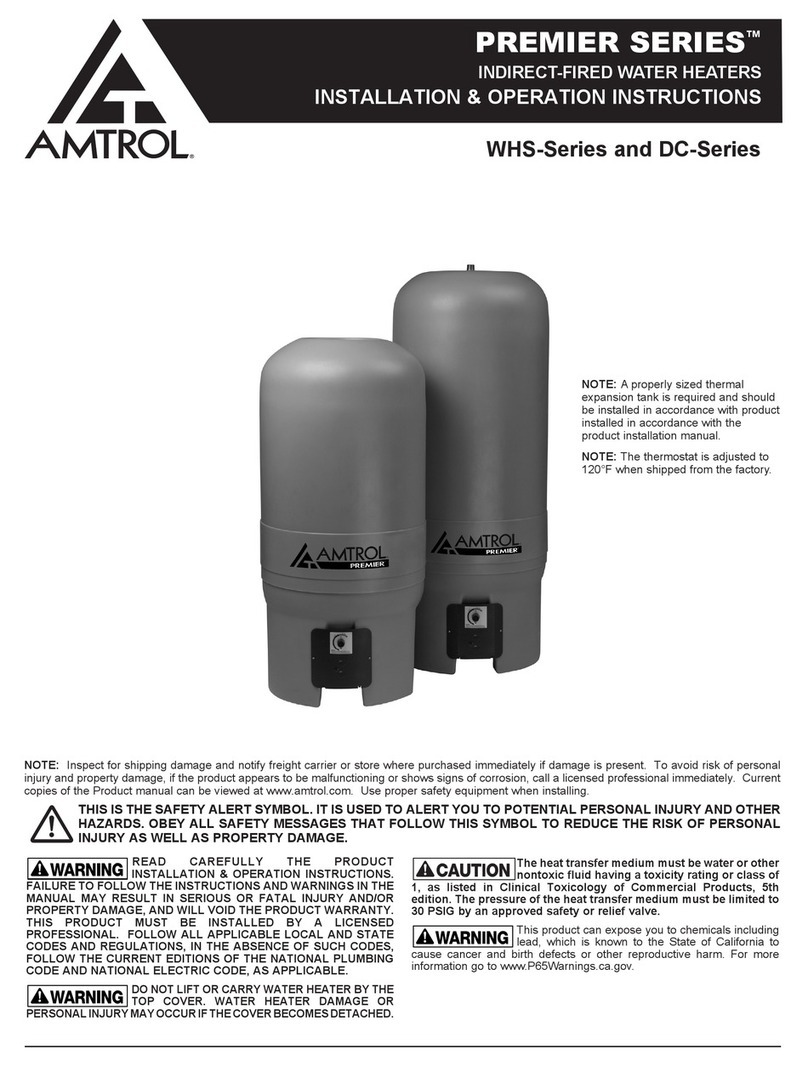

If installing on city water supply, a properly sized

thermal expansion tank is required with the water

heater and should be installed as set forth in the product installation

manual. Contact your water supplier or local plumbing inspector for

additional information.

Prevent pressure build-up in any existing internal

tankless coil. Do not plug incoming or outgoing

tappings in the internal tankless coil plate. Leave the coil in the boiler and

leave system connections open to prevent pressure build-up.

Electrocution hazard. The water heater must be

electrically grounded. Electrical supply must come

from the boiler side of boiler’s emergency shut-off switch in order to

prevent unsafe boiler operation.

Chlorine Aggressive Water: The water quality can

significantly influence the life of this Product. You

should test for corrosive elements, acidity, total solids and other relevant

contaminants, including chlorine and treat your water appropriately to

insure satisfactory performance and prevent premature failure.

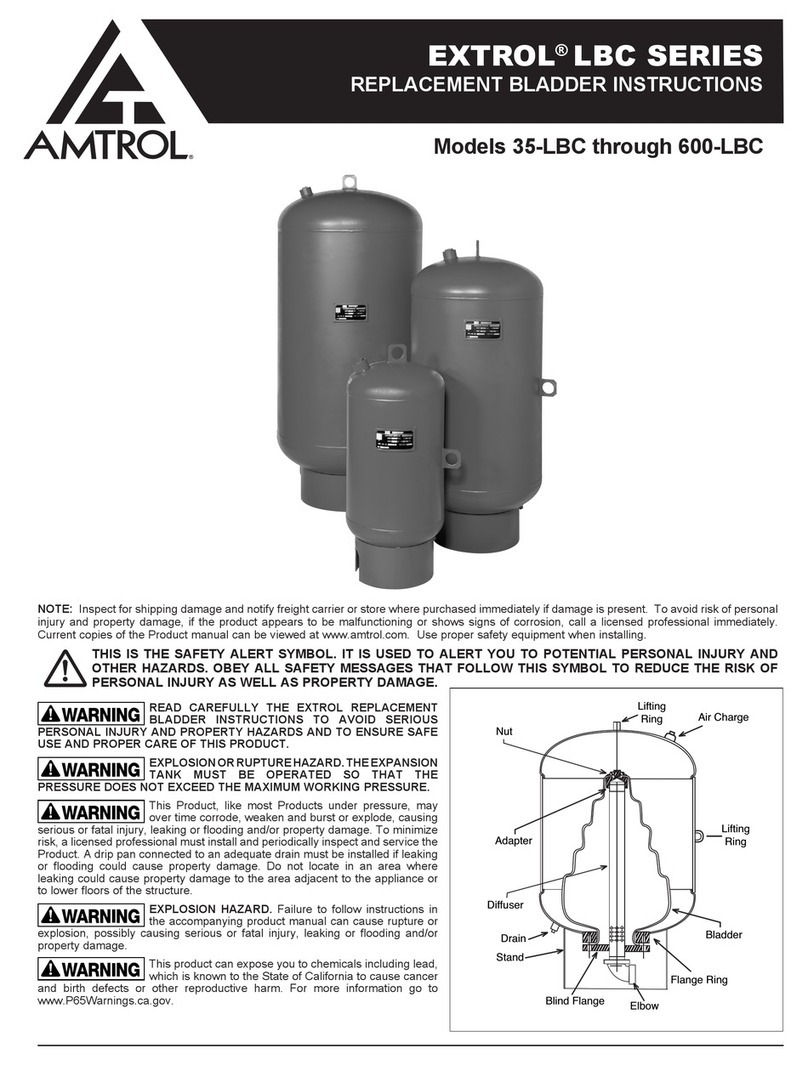

NOTE: Inspect for shipping damage and notify freight carrier or store

where purchased immediately if damage is present. To avoid risk

of personal injury and property damage, if the product appears to be

malfunctioning or shows signs of corrosion, call a licensed professional

immediately. Current copies of the Product Manual can be obtained at the

place of purchase. Use proper safety equipment when installing.

EXPLOSION HAZARD.The pressure of the heat

transfer medium must be limited to a maximum of

30 psig by an approved safety or relief valve on your boiler. The water

heater pressure must be limited to 150 psig maximum by the installation

of a temperature and pressure relief valve (included). The relief tube must

be plumbed to a suitable drain per code. No reducing coupling or other

restriction may be placed in this line.

This Product, like most Products under pressure,

may over time corrode, weaken and burst or

explode, causing serious or fatal injury, leaking or flooding and/or property

damage. To minimize risk, a licensed professional must install and

periodically inspect and service the Product. A drip pan connected to an

adequate drain must be installed if leaking or flooding could cause

property damage. Do not locate in an area where leaking could cause

property damage to the area adjacent to the appliance or to lower floors

of the structure.

EXPLOSION OR RUPTURE HAZARD. A relief

valve must be installed to prevent pressure in

excess of local code requirement or maximum working pressure

designated in the Product Manual, whichever is less. Do not expose

Product to freezing temperatures or temperatures in excess of the

maximum rated operating temperature.

If not installed by the boiler manufacturer, install a

low water cut-off or pressure reducing valve on your

boiler so that leaking will not result in a dry boiler which if the boiler

continues to fire, will cause an explosion hazard.

This unit must be installed as a separate heating

zone. Do not connect this unit to an existing heating

zone or feed boiler water directly through the coil as dangerous

over-heating will result.

Do not drain this appliance before shutting off the

supply valve and opening the relief valve or

another downstream fixture, as it will damage this unit. A vacuum breaker

should be installed to avoid damaging the liner. Damage to the unit and

leakage can occur if a vacuum breaker is not installed.

USE GLYCOL ONLY WITH DOUBLE-WALLED

HEAT EXCHANGER MODELS. Avoid risk of

ingesting a toxic glycol fluid. The heat transfer medium should be water.

If glycol must be used, it should only be used with double-walled heat

exchangers and closely monitored for leakage.

As in all plumbing products and water storage

vessels, bacteria can grow in this Product, especially

during times of non-use. Consult your local plumbing professional

regarding any steps you may wish to take to safely disinfect your home’s

plumbing system.

EXPLOSION OR RUPTURE HAZARD! A relief

valve must be installed to prevent pressure in

excess of local code requirement or maximum working pressure

designated in the Product Manual, whichever is less. At least once every

3 years or if discharge is present, a licensed contractor should inspect the

temperature and pressure relief valve and replace if corrosion is evident

or the valve does not function. FAILURE TO INSPECT THIS VALVE AS

DIRECTED COULD RESULT IN UNSAFE TEMPERATURE OR

PRESSURE BUILD-UP WHICH CAN RESULT IN PRODUCT FAILURE,

SERIOUS INJURY OR DEATH AND/OR SEVERE PROPERTY DAMAGE

AND VOID THE PRODUCT WARRANTY.

10. General Safety Information

-10-