Index

This Document… ................................................................................................................................1

Anchoring1000 Automatic Windlass..................................................................................................1

A Brief Introduction to the Product ...................................................................................................2

New Driving Gear ....................................................................................................................................... 2

Load-limiting and Auto-stop Functions .................................................................................................... 2

Digital Comptometer .................................................................................................................................. 2

Index ....................................................................................................................................................3

List of Products ...................................................................................................................................5

Delivery................................................................................................................................................6

Supplies ........................................................................................................................................................ 6

Anchor Davits.............................................................................................................................................. 6

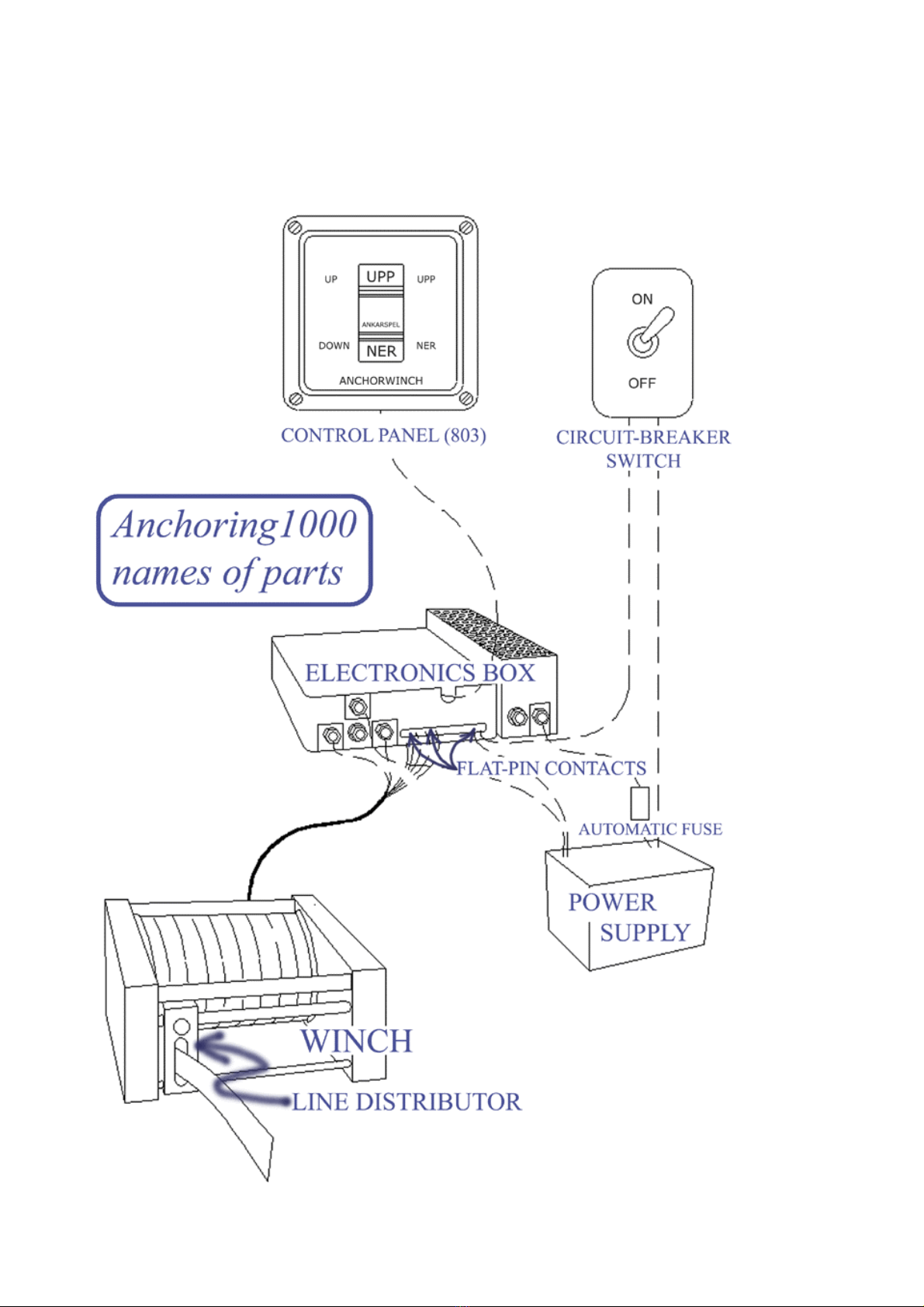

Designated Names...............................................................................................................................7

Important! ...........................................................................................................................................8

Power-supply Cabling................................................................................................................................. 8

Terminal Diagram...............................................................................................................................9

Winch and Chock Rollers......................................................................................................................... 10

Consider the B and M Dimensions .......................................................................................................... 11

Assembly Suggestions and Alternative Use......................................................................................12

Board Lead-through ................................................................................................................................. 13

Anchor Rollers........................................................................................................................................... 14

Anchor Davits............................................................................................................................................ 15

Fitting anchor davits 710 and 711 ........................................................................................................................... 15

Fastening and securing the anchor in holdfast position........................................................................................... 16

Casings ....................................................................................................................................................... 17

Recommendations for the Electrics and Placing of Electrical Components..................................18

Important!.................................................................................................................................................. 18

Setting the Auto-stop Function ................................................................................................................ 18

Please Observe!....................................................................................................................................................... 20

Electronic Settings for Anchor Davits 710 and 711................................................................................ 21

Control Panels ........................................................................................................................................... 22

Control Panels Connected in Series ........................................................................................................................ 22

Remote Control ......................................................................................................................................... 23

3