SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . 3

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

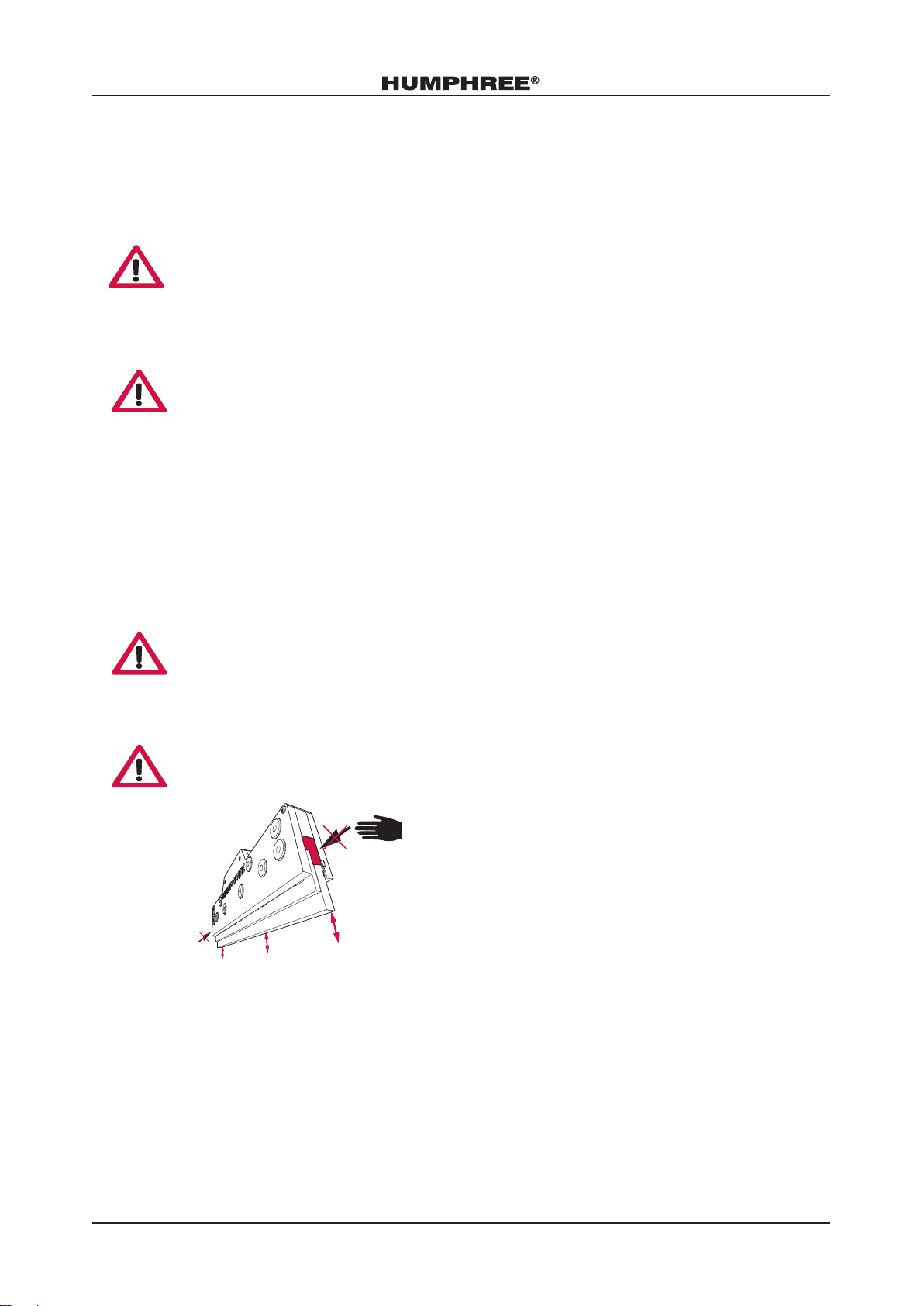

Interceptor Safety Information . . . . . . . . . . . . . . . . . . . . 3

Fin Safety Information . . . . . . . . . . . . . . . . . . . . . . . 4

IMPORTANT NOTICES . . . . . . . . . . . . . . . . . . . . . . . 5

COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . 6

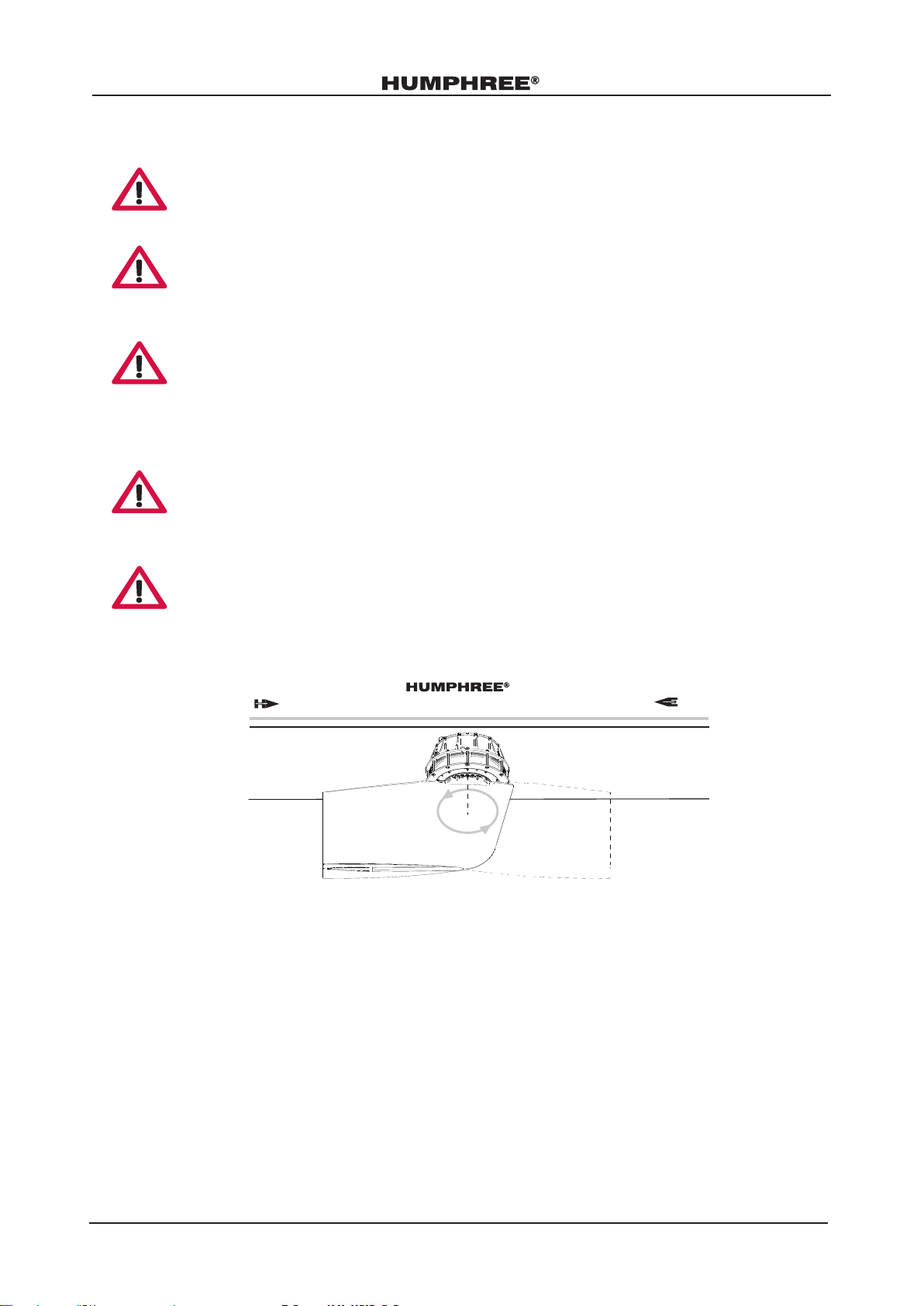

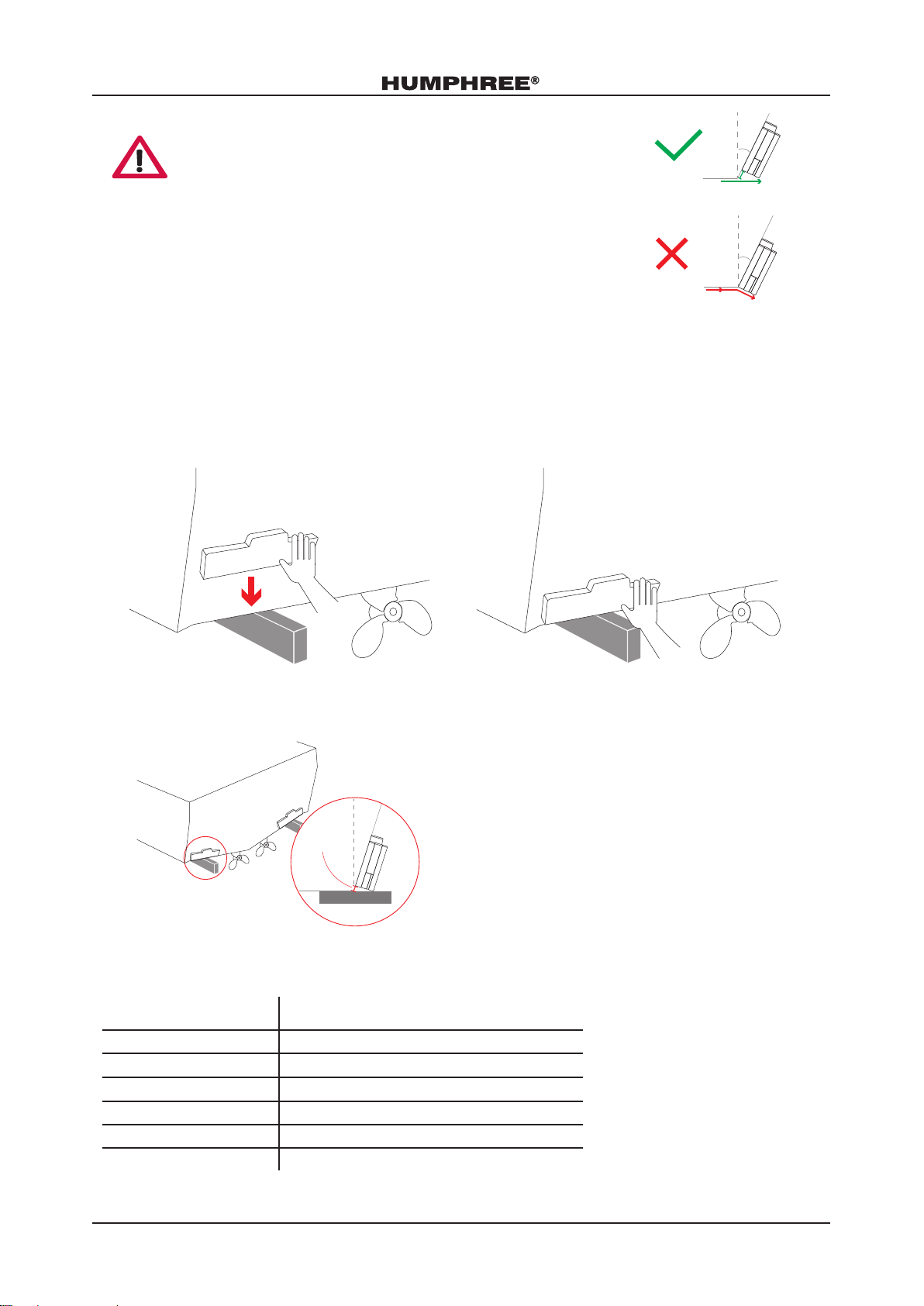

MOUNTING GUIDELINES . . . . . . . . . . . . . . . . . . . . . . 7

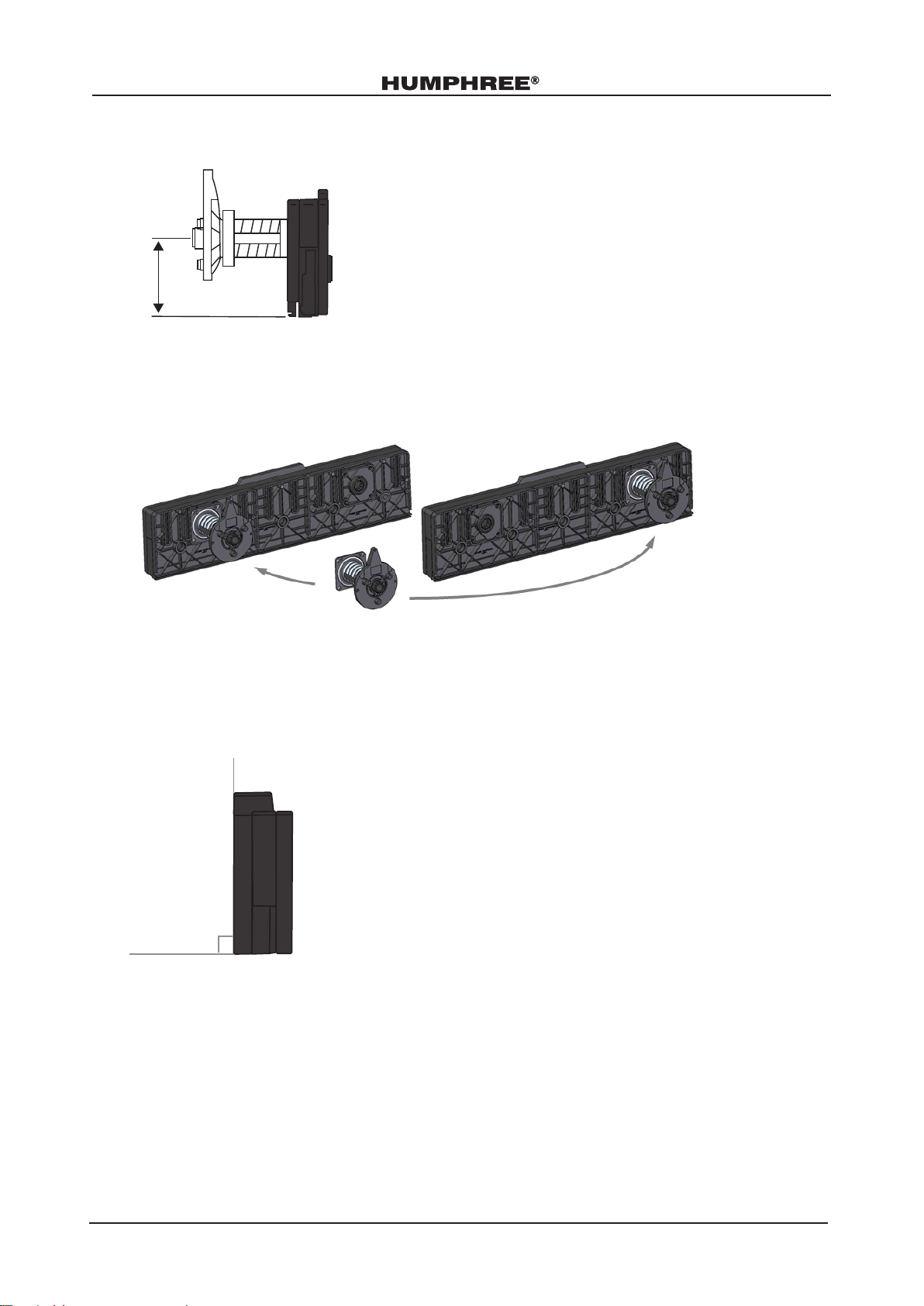

INTERCEPTOR INSTALLATION . . . . . . . . . . . . . . . . . . . . 11

Installation without Mounting Plate. . . . . . . . . . . . . . . . . . 11

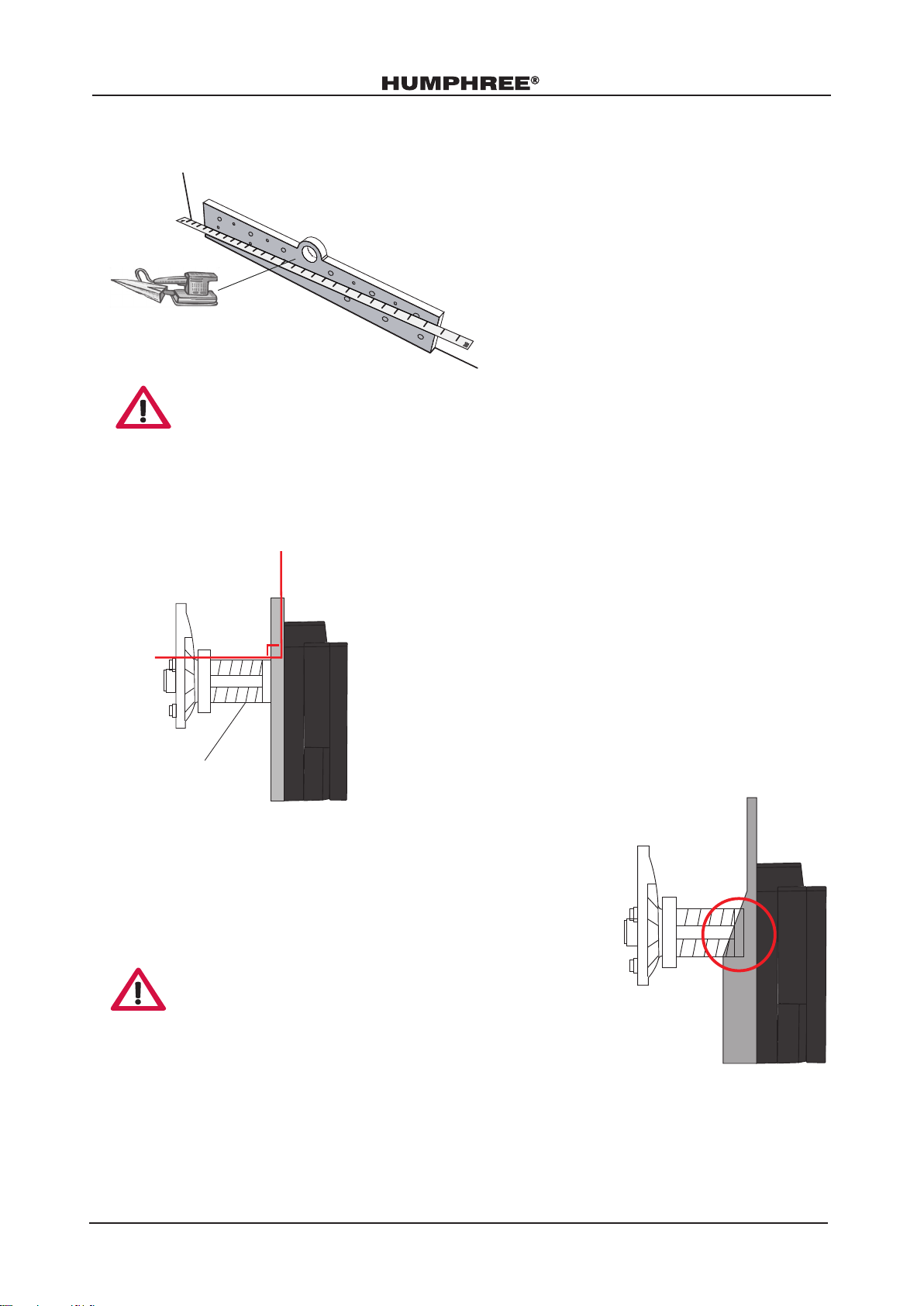

Installation with Mounting Plate . . . . . . . . . . . . . . . . . . . 16

Painting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Servo Installation . . . . . . . . . . . . . . . . . . . . . . . . . 27

FIN INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 28

RCU INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 29

CONTROL PANEL INSTALLATION . . . . . . . . . . . . . . . . . . 30

GPS INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 31

CABLE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . 32

GPS Cable Connection. . . . . . . . . . . . . . . . . . . . . . . 32

Control Panel and RCU Connection . . . . . . . . . . . . . . . . . 32

Servo Cable Installation . . . . . . . . . . . . . . . . . . . . . . 33

RCU Cable Installation . . . . . . . . . . . . . . . . . . . . . . . 33

End Termination Plug Installation . . . . . . . . . . . . . . . . . . . 33

EXTBUS and Analog Interface Cable Installation . . . . . . . . . . . . . 34

Key Switch Installation . . . . . . . . . . . . . . . . . . . . . . . 35

Power Supply Cable . . . . . . . . . . . . . . . . . . . . . . . . 35

START UP THE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . 36

APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Contents