1.General....................................................................................................................................................................................2

2.Specification........................................................................................................................................................................... 2

3.Function.................................................................................................................................................................................. 3

4.How to install..........................................................................................................................................................................3

4.1 Notes of installation:.......................................................................................................................................................4

4.2 Installation:..................................................................................................................................................................... 4

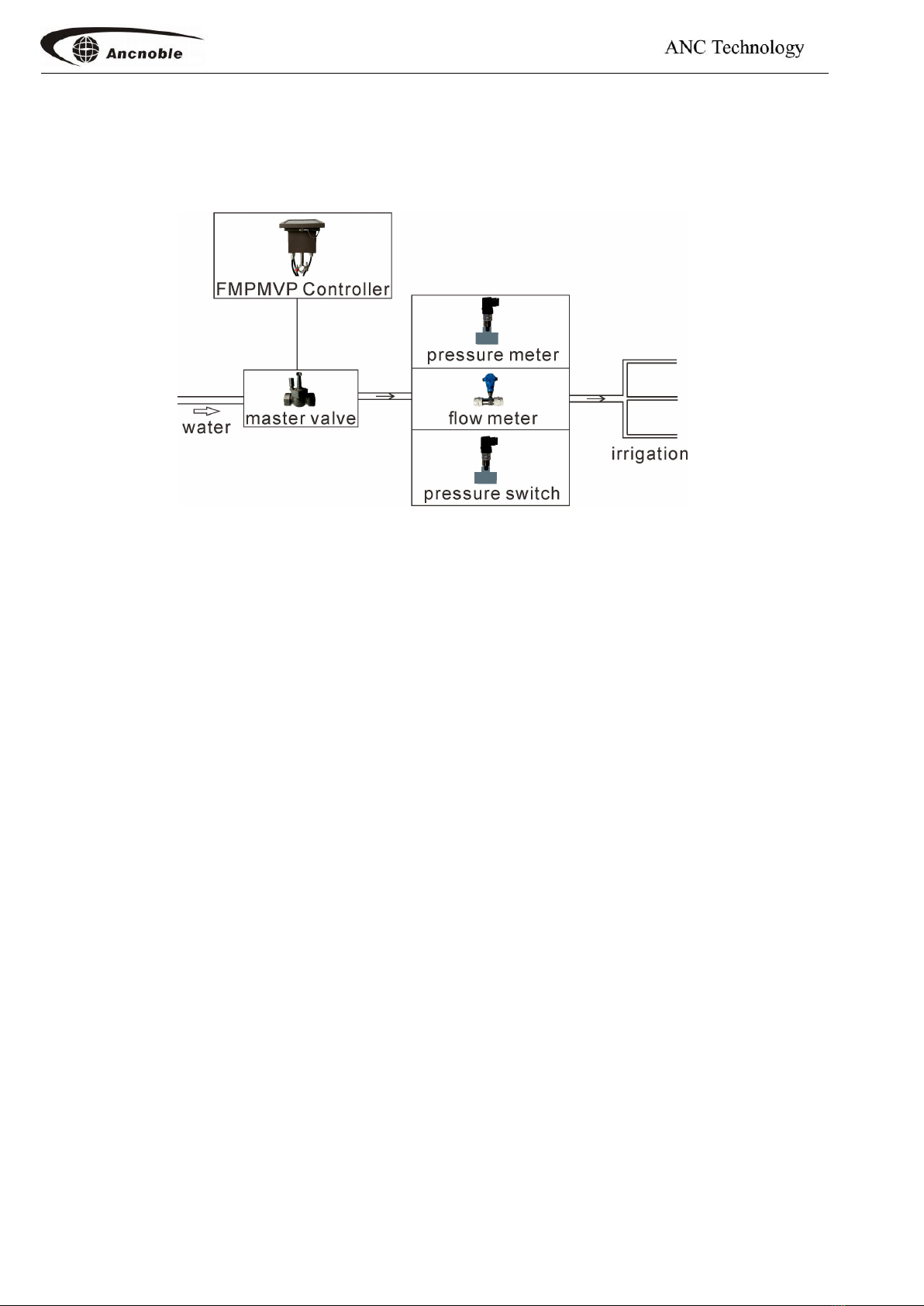

4.2.1 Pump connection illustration...............................................................................................................................4

4.2.2 How to install pressure sensor/switch................................................................................................................. 6

4.2.3 Valve connection..................................................................................................................................................7

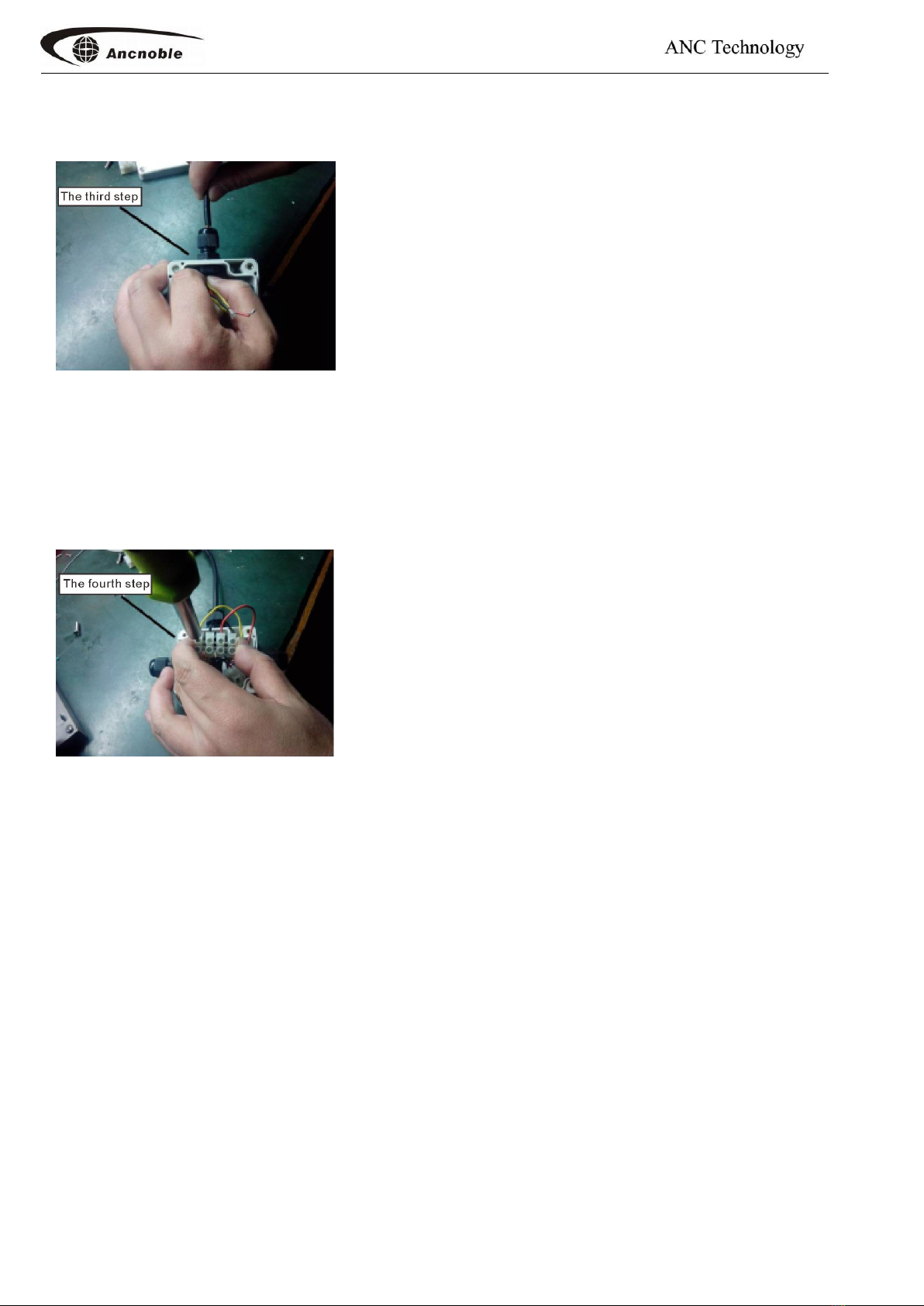

4.3 How to do connection inside the connection box.......................................................................................................... 8

4.4 Printed instruction on the box:..................................................................................................................................... 10

5.How to operate......................................................................................................................................................................10

5.1 Turn on Controller........................................................................................................................................................ 10

5.2 How to register to GG-002wifi/3g system main controller..........................................................................................11

5.3 How to establish wireless communication mesh network........................................................................................... 11

5.4 How to turn off controller.............................................................................................................................................13

5.5 Controller sleep.............................................................................................................................................................13

5.6 Field manual open/close............................................................................................................................................... 14

5.6.1 Field manual open/close....................................................................................................................................14

5.6.2 Field manual open/close pump..........................................................................................................................14

5.7 Explanation of LCD information..................................................................................................................................15

5.7.1 Main working LCD display:...........................................................................................................................15

5.7.2 LCD display for protective shut down of pump:............................................................................................16

5.7.3 Communication window:............................................................................................................................... 17

5.7.4 Detail information windows..............................................................................................................................17

6.How to setup......................................................................................................................................................................... 19

6.1 Flow Meter setup.......................................................................................................................................................... 19

6.1.1 Register/Remove flow meter.............................................................................................................................20

6.1.2 How to setup flow meter coefficient number....................................................................................................22

6.1.3How to setup flow rate range..............................................................................................................................22

6.1.4 How to clear total flow volume.........................................................................................................................23

6.2 Pressure meter setup..................................................................................................................................................... 24

6.2.1 Reg/remove pressure meter...............................................................................................................................24

6.2.2 Setup pressure range (0 - 1Mpa)....................................................................................................................... 24

6.3 Pump setup....................................................................................................................................................................24

6.3.1 Register and remove pump................................................................................................................................25

6.3.2 Set up pump protection sensor.......................................................................................................................... 25

6.3.3 Setup pump protective time delay.....................................................................................................................26

6.4 How to setup master valve............................................................................................................................................26

6.4.1 Register/Remove master valve..........................................................................................................................26

6.4.2 How to setup detection devices.........................................................................................................................27

6.4.3 Setup valve open/close time delay.................................................................................................................... 28

6.5 Help...............................................................................................................................................................................28

6.5.1 Questions and Answer....................................................................................................................................... 28

6.5.2 Communication link.......................................................................................................................................... 28

7. How to upgrade wireless field controllers..............................................................................................................................29