AND WEIRO WP 40 A Product guide

1

MANUAL BOOK

WP 40 A

DC INVERTER AIR PLASMA

CUTTING MACHINE

Jalan Arif Rahman Hakim 51 Ruko 21 Blok D-1, Surabaya

0851-0199-2232 | 031-5990089 |031-5997259 | [email protected] | adnsby.co.id

2

Input

Output

1-phase rectifier HF inverter HF transformer Rectifier & filter

Control circuit

HF arc start

1-

GENERAL REMARKS

1-1

Cutting machine features

This CUT series inverter air plasma cutter is kind of energy-saving metal cutting equipment with high efficiency

and light weight, adopts single tube IGBT HF inverter and advanced control technology. Its advantages are fast

speed, narrow & clean cut, small heat-affected zone, slightly deforming, material-saving, low cost, simple

operation and so on. These cutterspossess good static and dynamic characteristics, perfect control function, and

high-frequencyarc starting function. The characteristics are as follows:

-

Single phase power supply, small size, light weight and easy to operate;

-

Air filter pressure-reducing valve is built-in type, portable and easy to use;

-

Highly centralized arc energy, good stability, strong cutting ability;

-

Fast cutting speed (3~5 times of gas cutting), low cost;

-

Narrow, burnished, clean and almost vertical cutting edge;

-

Less work piece deformation;

-

Continuous adjustment of cutting current;

-

HF arc ignition, easy arc starting;

-

Strong power grid adaptability and low noise;

-

Multiplepatented technology, high reliability and durability.1-2 Functional

principle

This series of cutting machines adopts HF inverter technology. 1- phase input volt is

rectified by rectifier, inverted by inverter composed of single tube IGBT into HF AC,

reduced by HF transformer, rectified and filtered by HF rectifier, then output DC power suitable for cutting.

This progress increases the dynamic response capability, reduces the weight and the size of the

transformer and the reactor, improves the efficiency of

the machine, realizes energy-saving.

The special design of control circuit makes the machines enjoy high cutting

performance despite of changes like power grid voltage fluctuation, cutting cable

length. Features include easy arc starting, narrow, burnished and clean cutting edge, and continuously

adjustable cutting current.

Schematic diagram is shown in Fig. 1-2-1:

Fig. 1-2-1: Schematic diagram

3

1-3

Output characteristics

Fig.1-3-1: Output characteristics

1-4

Duty cycle

Duty cycle is percentage of 10 minutes that a machine can weld at rated load without overheating. If overheats,

thermostat(s) will close, output stops. Wait for fifteen minutes for themachine to cool down. Reduce amperage or

duty cycle before welding.

NOTE! Exceeding duty cycle can damage unit and void warranty.

Fig. 1-4-1: Duty cycle

U (V)

Uo

U

=

80

+

0

.

04I

80

0

Imin

Imax

I (A)

60

CUT40i

40

31

0

10 20 30 40 50 60 70 80 90

100

% DUTY CYCLE

Overheating

Minute

0

OR

Reduce Duty Cycle

15

WELD AMPERES

4

DANGEROUS!

WARNING!

Read the operating manual carefully before

installation.

Only qualified electricians may install and

operate.

ELECTRIC SHOCK can kill.

Keep the welder and work place in

good grounding.

GASES AND FUMES can be

dangerous & hazardous to your

health

Keep adequate ventilation,

anti-dust and exhaust

ARC RAYS, Spatter can injure

eyes and skins.

NOISE can cause permanent

hearing loss.

Wear protective clothing and

welding shield with filter.

FIRE, EXPLOSION can be

caused by hot slag, spatter and

sparks.

Remove combustibles from

working area.

Provide fire watch as well as fire

appliance in the working area.

Re ad th e o p er at i n g ma nu a l

c a re f ul l y b e f or e i n s t a l l a t i o n.

D AN G ER O U S ! WA R N IN G

O n l y q u a li fi e d e l e c t ric i a n s m a y

in s t a l l a n d o p e ra te .

EL E C T R I C S H O C K c a n k il l.

G A S E S A N D F U M E S c a n be

da n g e r ou s & h a z a rd o u s

to

y ou r

he a l th

Ke e p t h e w el d e r a n d w o r k p l a c e in

Ke e p a d e q u at e v e n ti l a ti o n , a n ti -d u s t

go o d gr o u n d i n g . an d ex h a u s t

A R C R A Y S, S p at te r

c an

in j u r e

ey e s

FI R E , E X PL O S I O N c an be c a u s e d by

an d s k i n s . hot s l ag , s p a tt e r a n d

s p a rk s .

N O I S E

c an

c a us e

p er m a n e n t

h ea r in g

Re m o v e c o m b u s ti b l e s f ro m w o r k i n g

loss. a rea.

W e ar p ro te c t i v e cl o th i n g and we l d in g

Pr o v i d e f ir e wa tc h a s wel l a s f i r e

s h ie l d w it h fi lt e r. ap p l i a n c e in t h e w o rk i n g

ar e a.

1-5

Applications

It can cut stainless steel, carbon steel, alloy steel, aluminum, copper, nickel and

titanium.

The cutting machine is designed for the following recommend areas:

-

Maintenance and repair

-

Steel construction

-

Metal shop

-

Office furniture supplies

-

Daily civil occasions

1-6

Warning label

The warning label is affixed onto the top of the cutting machine, and it must not be

removed or painted over.

Fig. 1-6-1: Warning label

5

2-

VERSIONS BRIEFS

Professional cutting of special materials requires special cutting parameters. Different

models of the power sources are matched to different cutting.

CUT40i

This series of cutting machine is small, light and portable. Adopt single tube IGBT HF

inverter technology, can perform fast speed cutting with clean and almost vertical

cutting edge.

6

3

- BEFORE COMMISSIONING

Warning! Operating the equipment incorrectly can cause serious injury and damage.

Do not use the machine until you have read "Safety rules".

3-1

Utilization for intended purpose only

The cutting machine may only be used for cutting. Utilization for any other purpose, or

in any other manner, shall be deemed to be “not in accordance with the intended

purpose”. The manufacturer shall not be liable for any damage resulting from such

improper use.

Utilisation in accordance with the “intended purpose” also comprises:

-following all the instructions given in this manual;

-performing all stipulated inspection and servicing work.

3-2

Machines set-up regulations

According to test, protection degree of this power source is IP23S. However, the

internal key components must be protected from direct soaking.

Warning! Amachine that topples over or falls from its stand can easily kill someone.

Place machine on an even, firm floor in such a way that it stands firmly.

The venting duct is a very important safety feature. When choosing the machine location,

make sure it is possible for the cooling air to enter and exit unhindered through the louvers on

the front and back of machine. Any electroconductive metallic dust from e.g. grinding-work

must not be allowed to get sucked into the machine.

3-3

Cutting machine connection

-

The cutting machine is designed to run on the mains voltage given on nameplate.

-

The mains cables and plugs must be mounted in accordance with the relevant technical

standard.

-

The power supply socket come with power source is designed to use strictly according to

the marked voltage.

Note! Incorrect electrical installations can lead to protection fails or partial fails. The

mains plug and socket, and its fuse protection, must be suitable for local power

suppl

7

Cutting

machine

Air

compressor

Ground

cable

Plasma

torch

4-

CUT40i

4-1

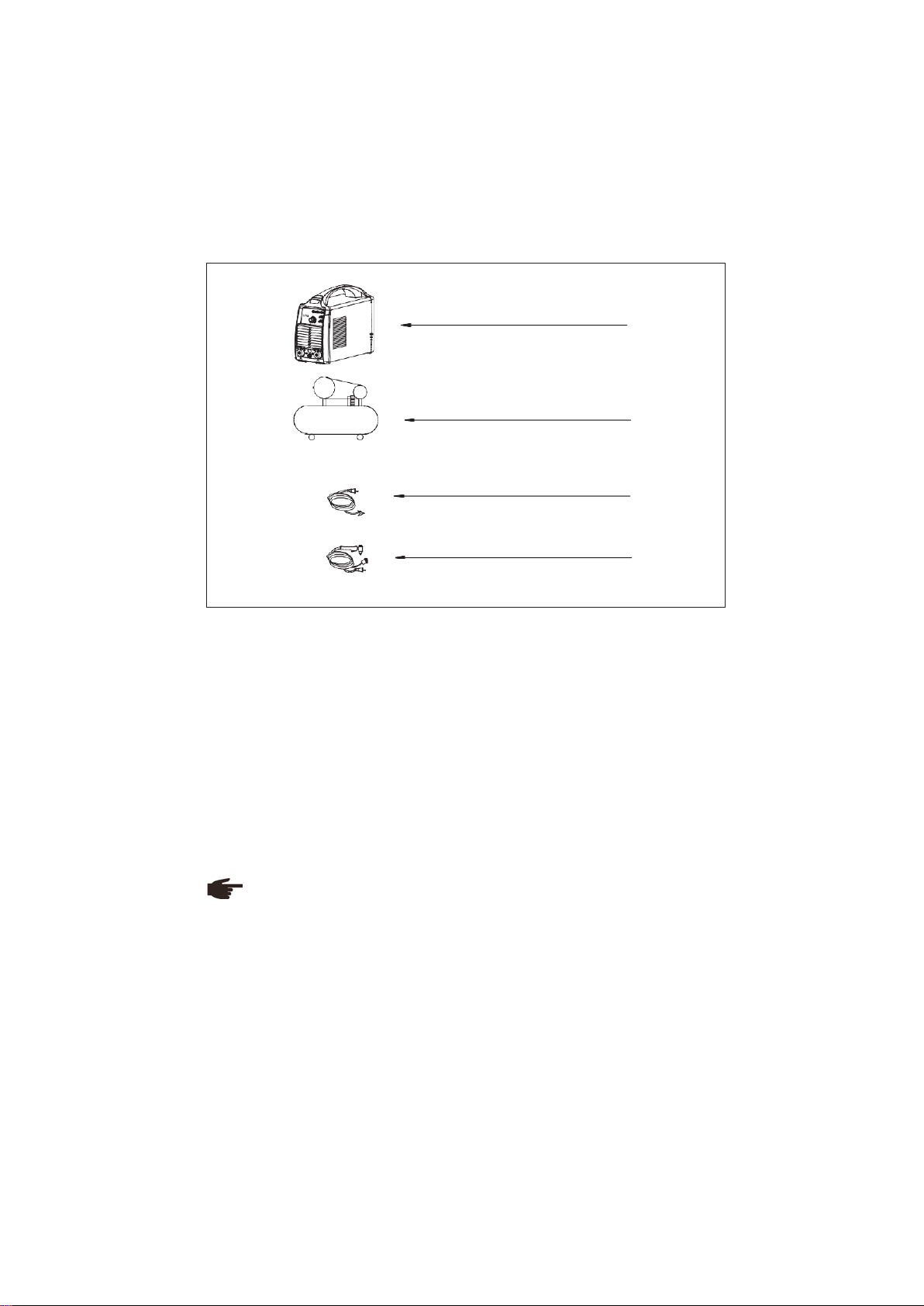

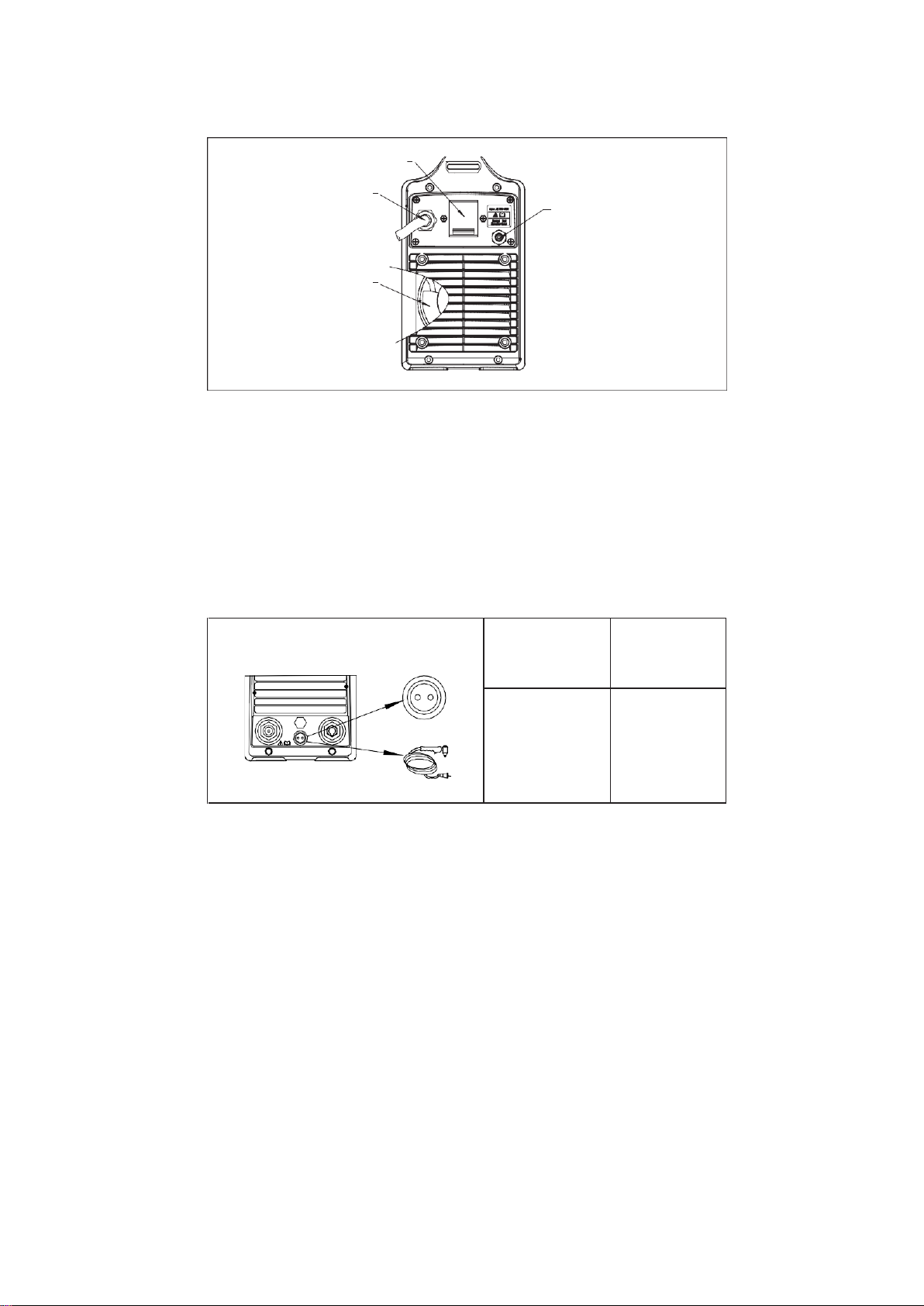

System components

This series of cutter can be equipped with many different accessories and can be used

in various sites with different configurations. (Refer to Fig. 4-1-1)

Fig. 4-1-1: System components

4-2

Basic equipments for cutting

Basic equipments are needed for normal cutting. Below are the lists:

CUT

-

Cutting machine

-

Ground cable

-

Plasma torch

-

Air compressor

4-3

Interface

The functions on the control panel are all arranged in a very logical way. The various

parameters needed for cutting are easy to select by pressing the appropriate button.

(Refer to Fig. 4-3-1)

Note! Your machine has certain functions that are not in accordance with this

operating manual, or vice versa. Also, certain illustrations may be slightly different

from the actual controls on your machine. However, these controls function in exactly

the same way.

8

1 2

3

7

4

5

25

30

CUT40i

35

20

15 40

CURRENT

(

A

)

9

6

8

Warning! Operating the equipment incorrectly can cause series injury and damage.

Do not use the functions described here until you have read and completely

understood this operating manual.

Front panel

Fig. 4-3-1: Front panel

1. Power on indicator

It is green light, indicates whether cutting machine is connected well to power supply. It lights

up when power on.

2. Gas pressure indicator

It is yellow light, does not light up during normal cutting; when input gas pressure of cutting

machine is lower than 0.35MPa, cutting machine will stop working automatically, protection

indicator lights up.

3. Over heat/fan locked-rotor protection indicator

It is yellow light, does not light up when cutting machine works normal. It lights up when inner

temperature is too high or fan is locked-rotor, and cutting machine will stop work automatically.

4. 2 step/4 step switch

On 2 step mode, press torch trigger to start cut, release to stop, suit for short cut seam. On 4

step mode, can release torch trigger to perform cut after pressing torch trigger and starting

arc, re-press and release torch trigger to stop cutting, suit for long cut seam.

5. Gas test/cut switch

On gas test mode, check whether gas circuit is normal. On cut mode, start normal cut.

6. Protective cover of negative output terminal and gas-electric connector (-)

Connect gas-electric connector of cutting torch.

7. Current adjustment knob

For regulating the cutting current.

8. Protective cover of positive output terminal and ground cable quick socket (+)

Connect with work piece via ground cable.

9. Control socket

Connect with control connector of cutting torch.

Rear panel

9

Fig. 4-3-2: Rear panel

1. Circuit breaker

Switch for single-phase AC220V±15% power. Turn on this switch (on the position: “ON”), then

the power on indicator lights up, and the fan runs.

2. Power supply cable

Three pin wires, the mixed-colored wire must be firmly grounded; the rest 2 wires connect to

1- phase AC 220V±15% 50/60Hz power supply.

3. Gas inlet

Connect with compress gas source by gas hose.

4. Fan

Cool down the heat components in the cutting machine.

4-4

Connections

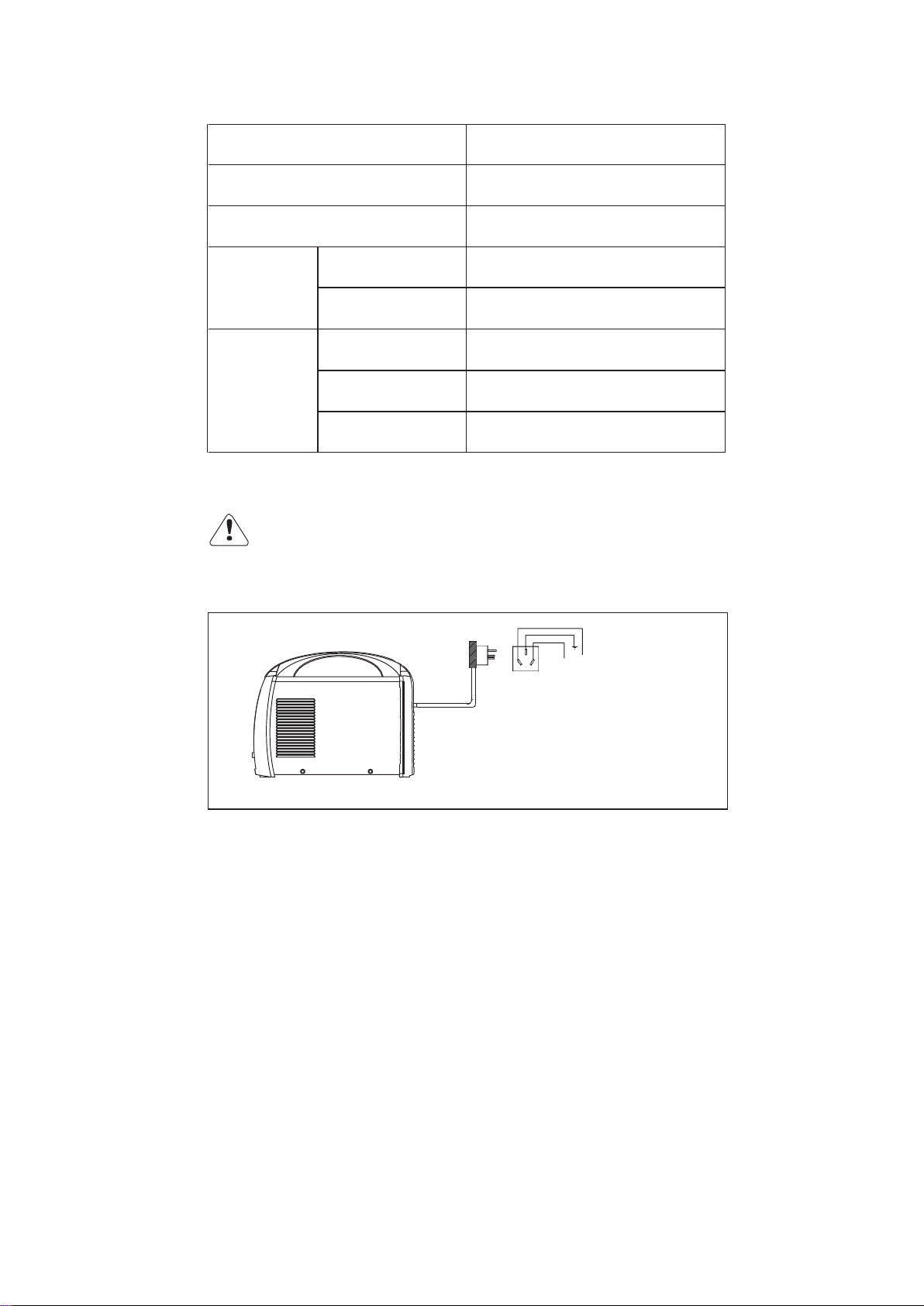

Control socket

1 2

Socket Pin

Description

1, 2

Torch trigger

Table 4-4-1: Connections

Output socket

The output socket of this cutting machine is fast plug-in type.

1

2

ON

3

OFF

4

10

Gas hose

Air

compresser

Input

cable

CUT40i

25 30

20

35

15

40

CURRENT(A )

1-phase

Work piece

Ground

cable

Grounding

Cutting

torch

gas-electric

connector

Control cable

Torch

Fig. 4-4-1: Output socket

4-5

Installation and operation

Warning! An electric shock can be fatal. If the machine is plugged into the mains

electricity supply during installation, there is high risk of very serious injury and

damage. Do not use the functions described here until you have read and

completely understood “Safety Rules” in the beginning. Only carry out work on the

machine when

-

the mains switch is in turn-off position,

-

the machine is unplugged from the mains.

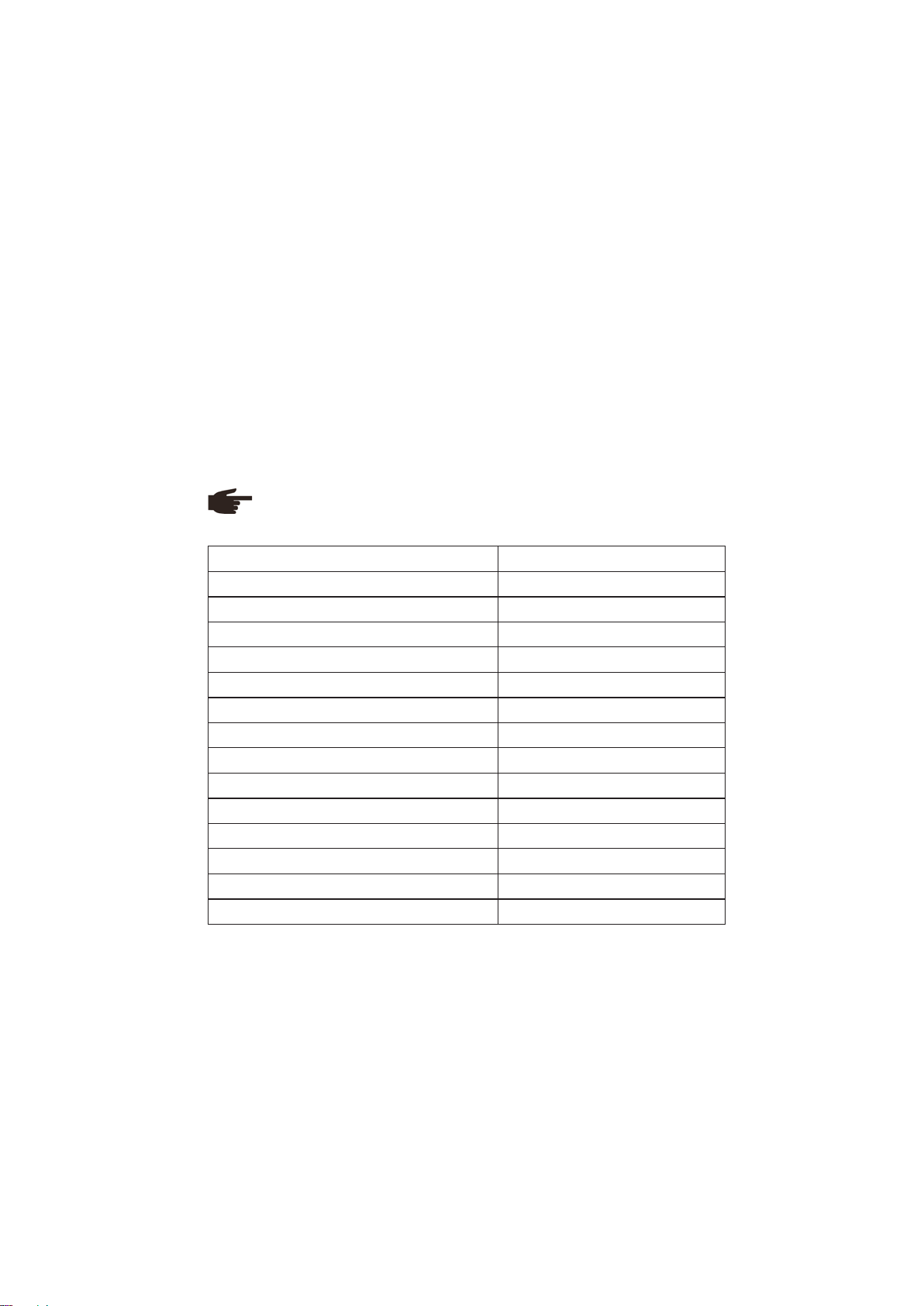

CUT40i cutting machine wire diagram as Fig. 4-5-1:

Fig. 4-5-1: Installation of CUT40i

Input power supply cable installation

Please note the size of fuse and circuit breaker in the table below are for reference only.

Fast plug

-

in type

11

E

L

N

E

GND

N L

GND/PE Earth

Ground

Yellow-Green mixed wire is used for

grounding! Not connected to zero wire!

Please connect according to picture or other

correct way. Please disconnect mains

power when connecting!

Model

CUT40i

Power supply

1- phase AC 220V±15%, 50/60Hz

Min. power capacity (KVA)

9

Input volt.

protection

(A)

Fuse

50

Circuit breaker

60

Min. cable size

(mm2)

Input cable

2.5

Output cable

16

Protective GND wire

2.5

Table 4-5-1: Input power supply cable installation

The connection between input cable and distribution box (Fig. 4-5-2)

Warning!

-

Never connection when equipment is power on!

-

The connection must be carried out by a qualified electrician!

-

Do not connect two units of power sources to the same circuit breaker!

-

Connected to the correct input voltage, circuit breaker, input cable as per the

specification on Table 4-5-1.

Fig. 4-5-2: Connection between input power supply cable and switch box

12

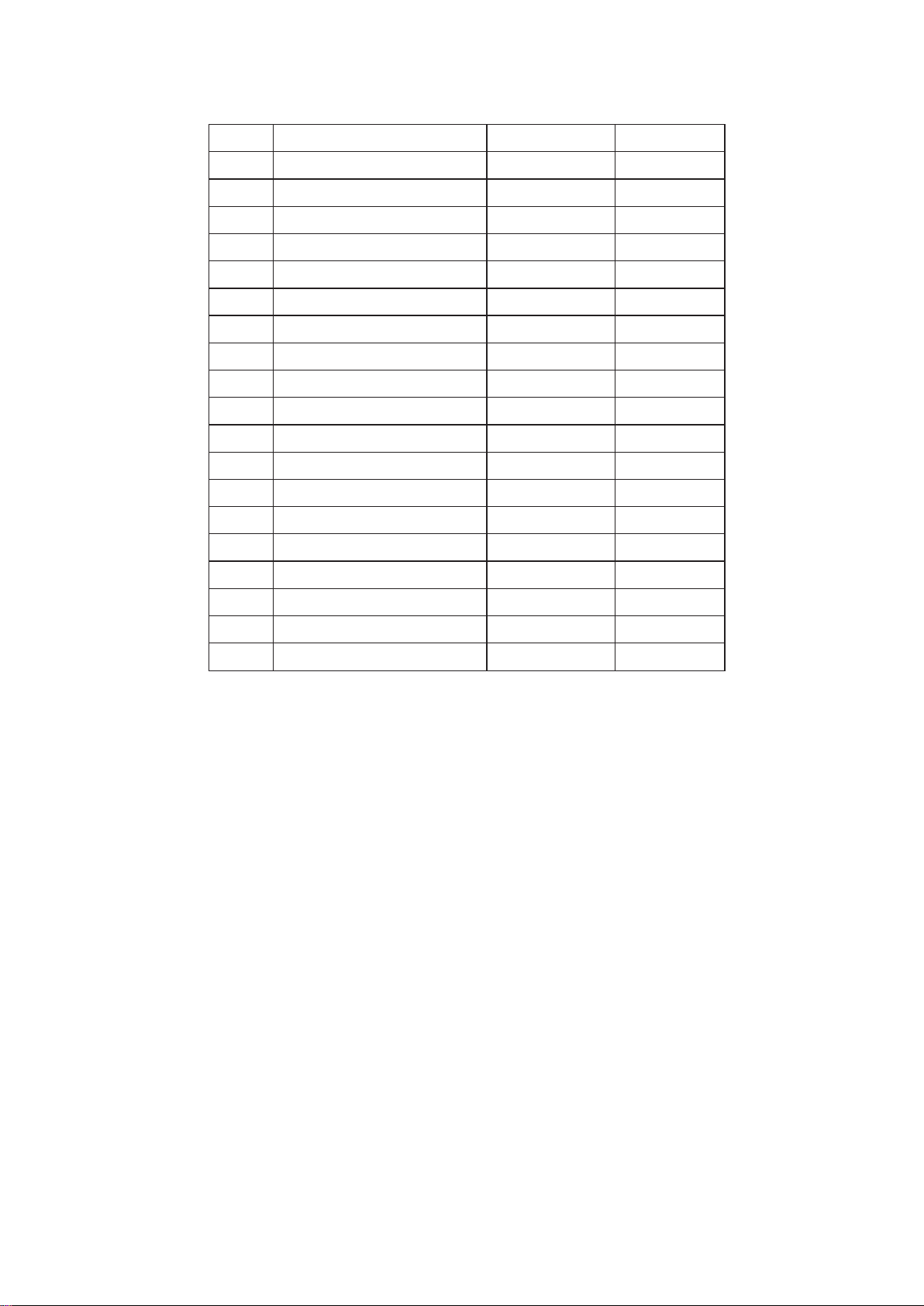

Power socket and using region

A: 2-plug flat type

B: 2-plug flat + GND

round hole type

C: 2-plug flat 8 type

D: 3-plug flat 8 type

E: 2-plug round (4.0mm) type

F: 2-plug round (4.0mm) type

G: 2-plug round + GND

round hole type

I: 3-pin flat type

K: 3-pin round type

M: Switzerland type

N: Italy type

O: Denmark type

Table 4-5-2: Power socket selection

Country

Type

Country

Type

Asian-Pacific region

Hong-Kong

I

Macau

E, G

Vietnam

A, B, E, G

Thailand

A, B

Malaysia

I

Singapore

I

Indonesia

E, G

India

I, K

Australia

C, D

New-Zealand

C, D

Japan

A, B

Korea

E, G

13

Country

Type

Country

Type

Middle East region

SaudiArabia

A, B, I

Iran

E

Dubai

G

Europe region

Italy

E, N

Austria

E, F, G

Poland

E, F, G

Hungary

F, G

Greece

E, F, G

Belgium

E, F, G

Netherlands

E, F, G

United Kingdom

I

France

E, F, G

Switzerland

E, M

Spain

E, F, G

German

E, F, G

Finland

E, F, G

Denmark

E, F, G, O

Russia

E, F, G

Turkey

E, F

America region

United States

A, B

Canada

A, B

Mexico

A, B

Columbia

A, B

Venezuela

A, B

Brazil

A, B, E

Peru

A, B, E

Argentina

C, D

Chile

E, N

Uruguay

E

Africa region

Rep. South Africa

K

Table 4-5-3: Using region selection

Cutting

Warning! Operating the equipment incorrectly can cause serious injury and damage.

Do not use the functions described here until you have read and completely

understood the following documents:

-

“Safety rules”

-

“Before commissioning”

Warning! Preparing when plug is on and power switch is in turn-on position may

cause danger. Switch it off and unplug it from the mains when preparing.

1. Plug the ground cable into output socket (+), and tighten it firmly;

2. Connect the other end of the ground cable to the work piece;

3. Plug the 2-pin plug of torch into the cutting machine control socket;

4. Plug gas-electric connector of torch to cutting machine gas-electric socket, and tighten it

firmly;

14

Note! When connect ground cable, power off cutting machine, align plug lug boss with socket

gap, insert and rotate in clockwise direction until fix well. Must ensure good connection

between plug and socket, otherwise high heat may burn plug and socket.

5. Air filter pressure-reducing valve is installed inside of cutting machine, connect its gas inlet

with gas outlet of air compressor;

Note! Max. working pressure of air compressor is 0.8Mpa, min. is 0.6 Mpa, gas flow rate ≥

250L/min.

6. Connect with single phase 220V power supply;

7. Turn on the power switch of the cutting machine, power on indicator lights up;

8. Open air valve of air compressor, gas flows;

9. Pull up gas adjustment knob of pressure-reducing valve to adjust pressure, press torch

trigger, rotate knob to adjust pressure to 3.5-5 bar, and press down the knob to lock the

adjusted value;

10. Adjust proper cutting current according to work piece thickness;

11. Contact torch nozzle with work piece arc starting point;

Note! Usually start cutting at edge of work piece, also can start cutting at any point of work

piece, at this time, should incline torch so as to blow off molten metal, and form original cut.

12. Press torch trigger to start arc;

On 2 step mode: press torch trigger-gas feeds-HF arc start-arc starts-start cutting-release

torch trigger-gas post flows-stop cutting;

13. Release torch trigger to stop cutting, and then remove torch after gas stops feeding;

14. Close air valve of compressor.

4-6

Technical data

Note! Please use the machine under the allowed power supply voltage range

marked in the nameplate. The technical data with the basic input voltage are listed as

the Table 4-6-1.

Model

CUT40i

Input volt/frequency

Single phase AC220V±15%/50/60HZ

Rated input capacity (KVA)

7

Rated input current (A)

32

Rated duty cycle (%)(40℃)

60

Output current range (A)

15~40

Output open circuit voltage (V)

285

Max. carbon steel cutting thickness (mm)

12

Optimal carbon steel cutting thickness (mm)

1~7

Weight (Kg)

9

Dimension (cm3)

39×16×30

Insulation class

F

Post-gas time (S)

30

Arc-starting type

Contact

Standard cutting torch

PT31

Table 4-6-1: Technical data

15

4-7

Main components list

Fig. 4-7-1: Inner structure

13

12

7

9

1

2

11

8

17

3

10

4

5

19

18

16

6

15

14

16

No.

Item

Stock no.

Remark

1

Knob

745003-00034

220V, 50Hz

2

Potentiometer

720031-00105

220V, 50Hz

3

Quick socket

740002-00079

220V, 50Hz

4

Socket copper core with gas hole

766001-01690

220V, 50Hz

5

Aviation socket

740001-00214

220V, 50Hz

6

Display board

220503-00126

220V, 50Hz

7

Circuit breaker

745011-00068

220V, 50Hz

8

Fan

746002-00025

220V, 50Hz

9

Power transformer

220179-00616

220V, 50Hz

10

Solenoid valve

752001-00037

220V, 50Hz

11

Pressure-reducing valve

766003-02164

220V, 50Hz

12

Rectifier bridge

735004-00005

220V, 50Hz

13

Fuse

745007-00045

220V, 50Hz

14

Aluminum electrolytic capacitor

722004-00105

220V, 50Hz

15

Output reactor

763004-00159

220V, 50Hz

16

IGBT single tube

735003-00011

220V, 50Hz

17

Main transformer

763002-00024

220V, 50Hz

18

Main control drive board

210580-00644

220V, 50Hz

19

Over voltage protection board

220900-00242

220V, 50Hz

Table 4-7-1: Main components list

Note: If no special remarks, the input voltage mentioned in above table is single phase.

17

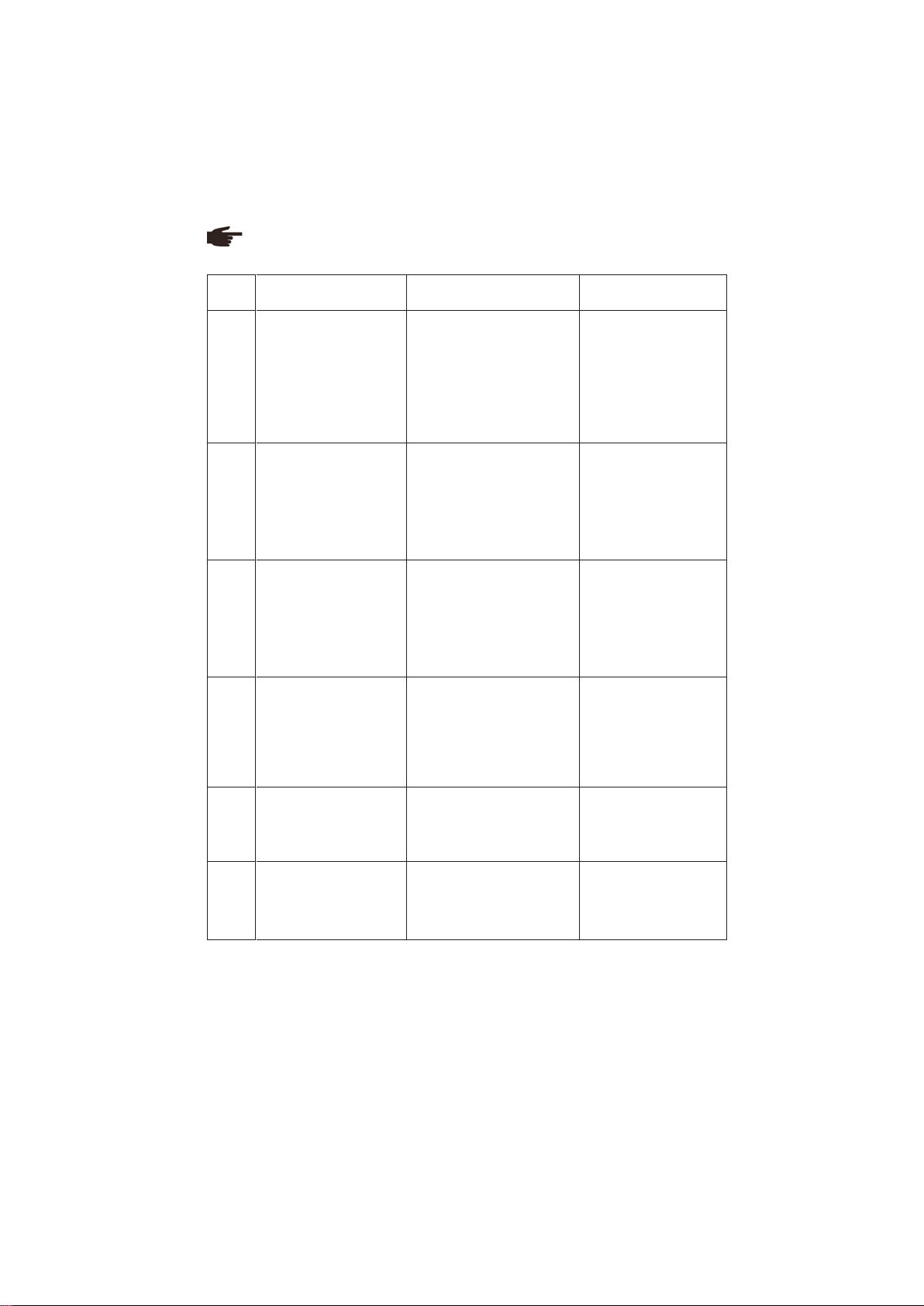

5-

TROUBLE SHOOTING

Note! The following troubles and causes are uncertain. However, during the process

of normal using conditions, that might happen.

NO.

TROUBLE

CAUSES

REMEDY

1

Power on indicator

does not light up, fan

does not run, no

output when machine

switches on

1)

Power switch is

damaged

2)

No electricity on the

electricity grid

3)

Connect to 380V power

1)

Check power

switch, fan connection

between main control

board and display

board

2)

Check power supply

on the electricity grid

3)

Check

2

Power on indicator

lights up, but

protection on

indicator does not

light, and no output

1)

Output cable does not

connect well

2)

Bad connection of

joints, especially torch

trigger cable connection

3)

Display board is

damaged

1)

Check output cable

connection

2)

Check connection

3)

Check and repair

3

Protection on

indicator lights up

1)

Inner temperature is too

high

2)

Temperature relay is

broken

3)

Fan is locked-rotor, fan

cable is broken

4)

Gas shortage

1)

Let the machine

cool down

2)

Replace

3)

Check

4)

Check gas pressure

4

Circuit breaker on the

switchboard trips

while in cutting

1) The following devices

may be damaged: power

IGBT tube, output diode,

input rectifier bridge,

thermistor, electrolytic

capacitor

1) Check and replace

5

The cutting current is

unstable

1)

Potentiometer is broken

2)

Current sensor is

damaged

3)

Bad connection of joints

1)

Check and replace

2)

Check and replace

3)

Check and replace

6

Cutting current is not

adjustable

1) Current adjustment

potentiometer on front

panel is damaged

1) Check and replace

18

NO.

TROUBLE

CAUSES

REMEDY

7

No gas flows out

during cutting

1)

Solenoid valve is

damaged

2)

Gas flow is blocked

3)

The output air pressure

of air filter pressure-

reducing valve is too high

1)

Check and replace

2)

Check gas flow

3)

Regulate pressure

knob on the filter to

reduce air pressure

8

Too wide cut

1)

Slow cutting speed

2)

Nozzle is burn out

1)

Increase cutting

speed

2)

Replace

9

Non-vertical cut

1)

Nozzle is burn out

2)

Non-alignment of nozzle

to electrode

3)

Cutting torch is not

vertical to work piece

surface

1)

Replace

2)

Align the nozzle and

the electrode

3)

Adjust to vertical

position

Table 5-1: Trouble shooting

19

6

- CARE AND MAINTENANCE

Before open the machine

Warning! An electric shock can be fatal. Before doing any work on the machine:

-

Switch it off and unplug it from the mains

-

Put up a clearly legible and easy-to-understand warning sign to stop anybody

inadvertently switching it back on again

-

Discharge the capacity if necessary

-

Bolt in outer case also works for ground connection. Never use other bolt which

cannot work for ground connection

Maintenance of cutting machine

Please follow the instructions as below to ensure normal use of cutting machine

-

Conduct safety check at regular intervals (see “Safety rules”)

-

Dismantle machine side panels and clean machine inside with clean and low-pressure

compressed air by professional technician, not less than twice per year. Clean the

components at a certain distance only

-

If a lot of dust has accumulated, clean the cooling-air ducts

Daily maintenance

Disconnect main power before maintenance

3 months

Change

illegible

labe

Repair or

replace

broken

cable

Clean and

tighten

welding

terminal

6 months

Blow or suck inner part,

and clean every month

when working in

harsh environmental

condition

Fig. 6-1: Daily maintenance

20

(-)

Plasma

cutting

t orch

Work piece

Negative

t erminal

Cutting

m achine

R

Arc

m aintenance

cabl e

Electrode

S

Nozzle

Positive

term inal

Work

pie ce

7

- BASIC CUTTING TECHNIQUE

Note! This section being general welding technique guide is for reference only.

Specific functions of your machine please refer to previous chapters.

Air plasma cutting is a cutting method using plasma arc thermal energy. When cutting, use

plasma arc to melt work piece, blow molten metal by jet stream to form cut. Air plasma cutting

can cut almost all metal materials, especially for high alloy steel and nonferrous metal which

cannot be cut by flame cutting.Advantages are as follows: highly centralized arc energy, good

stability, strong cutting ability; high cutting speed (3~5 times of gas cutting); low cost; arrow,

burnished, clean and almost vertical cutting edge; less work piece deformation.

Fig. 7-1: Cutting process

1.Plasma arc type

According to power source connecting method, there are two kinds: transferred arc and non-

transferred arc.

(1)

Transferred type

Power source negative output terminal is connected with electrode; positive terminal is

connected with work piece. Plasma arc is generated between electrode and work piece. First,

it needs to ignite plasma flame flow between electrode and nozzle, and plasma airflow makes

plasma flame flow contact with work piece to form plasma arc. Plasma arc formed by this

transferred method is called transferred arc. Transferred arc can reduce nozzle burning

caused by arc starting or liquid metal spatter.

Fig. 7-2: Transferred type

This manual suits for next models

1

Table of contents