Kunststoffschweißtechnik

Contents

20.08.2014 Working instructions WIDOS 4000 WM Page 5 of 68

1. DESCRIPTION OF PRODUCT........................................................................................ 7

1.1. Usage and purpose-oriented use........................................................................................7

1.2. Safety measures ...................................................................................................................7

1.3. Conformity.............................................................................................................................7

1.4. Marking of product ...............................................................................................................8

1.4.1. Technical data ................................................................................................................8

1.4.1.1. WIDOS 4000 WM general data ................................................................................8

1.4.1.2. Basic unit ...................................................................................................................8

1.4.1.3. Heating element.........................................................................................................9

1.4.1.4. Planer.........................................................................................................................9

1.4.1.5. Hydraulic aggregate...................................................................................................9

1.5. Wear Parts .............................................................................................................................9

1.6. Tools and Accessories.......................................................................................................10

1.7. Equipments (optional)........................................................................................................10

2. SAFETY RULES............................................................................................................ 13

2.1. Explanation of the different symbols................................................................................13

2.2. Obligations of the owner....................................................................................................14

2.3. Obligations of the worker ..................................................................................................14

2.4. Measure of organization ....................................................................................................14

2.5. Information about safety precautions ..............................................................................14

2.6. Instructions for the staff ....................................................................................................14

2.7. Dangers while handling the machine ...............................................................................15

2.8. Dangers by electrical energy.............................................................................................15

2.9. Dangers by hydraulic .........................................................................................................15

2.10. Specific dangers.................................................................................................................15

2.10.1. Danger of combustion by heating element and welding area......................................15

2.10.2. Danger of crushing between machine tables / clamping tools ....................................16

2.10.3. Danger of cutting and drawing-in of clothes by the planer...........................................16

2.10.4. Danger of stumbling over electric wire.........................................................................16

2.10.5. Risk of injury by noises ................................................................................................16

2.11. Structural modifications on the machine.........................................................................17

2.12. Warranty and Liability ........................................................................................................17

3. FUNCTIONAL DESCRIPTION ...................................................................................... 19

4. OPERATING AND INDICATING ELEMENTS .............................................................. 21

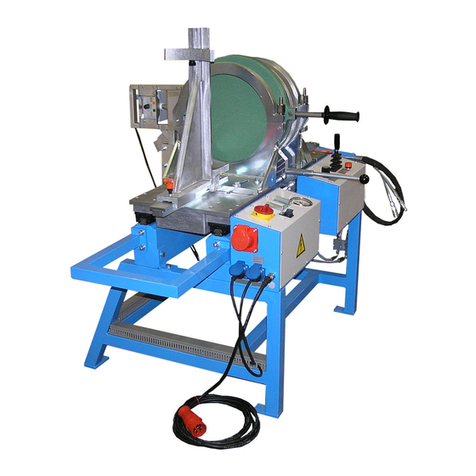

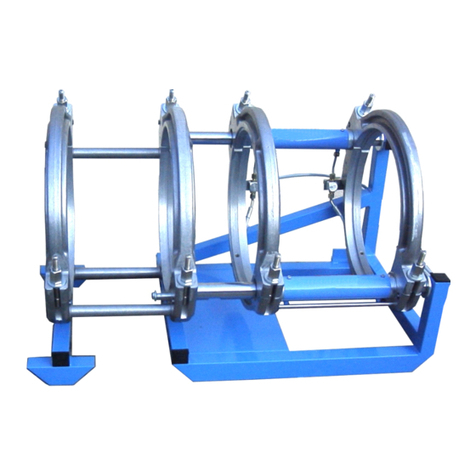

4.1. Machine overview ...............................................................................................................21

4.2. Horizontal adjustment (mismatch compensation)..........................................................22

4.3. Elements at the heating element.......................................................................................23

4.4. Main switch..........................................................................................................................23

4.5. Elements at the planer........................................................................................................24

4.6. Switch cabinet.....................................................................................................................25

4.7. Clamping tools with 15° .....................................................................................................25

4.7.1. How to install the reducer inserts (optional).................................................................26