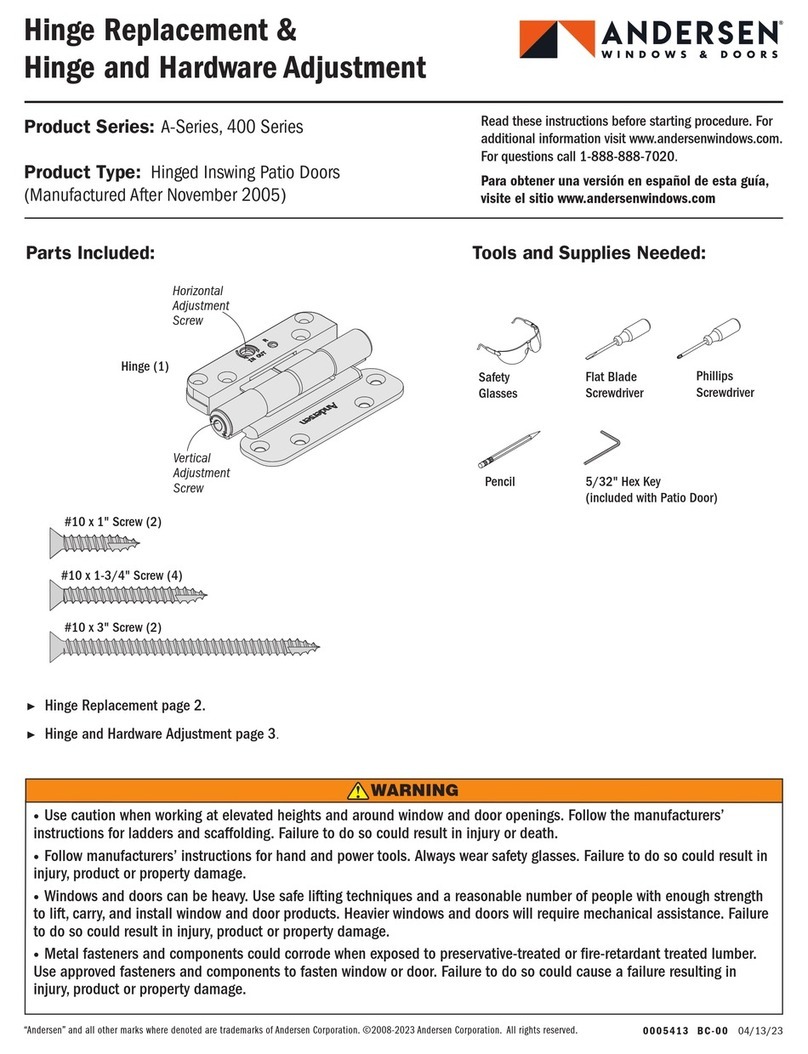

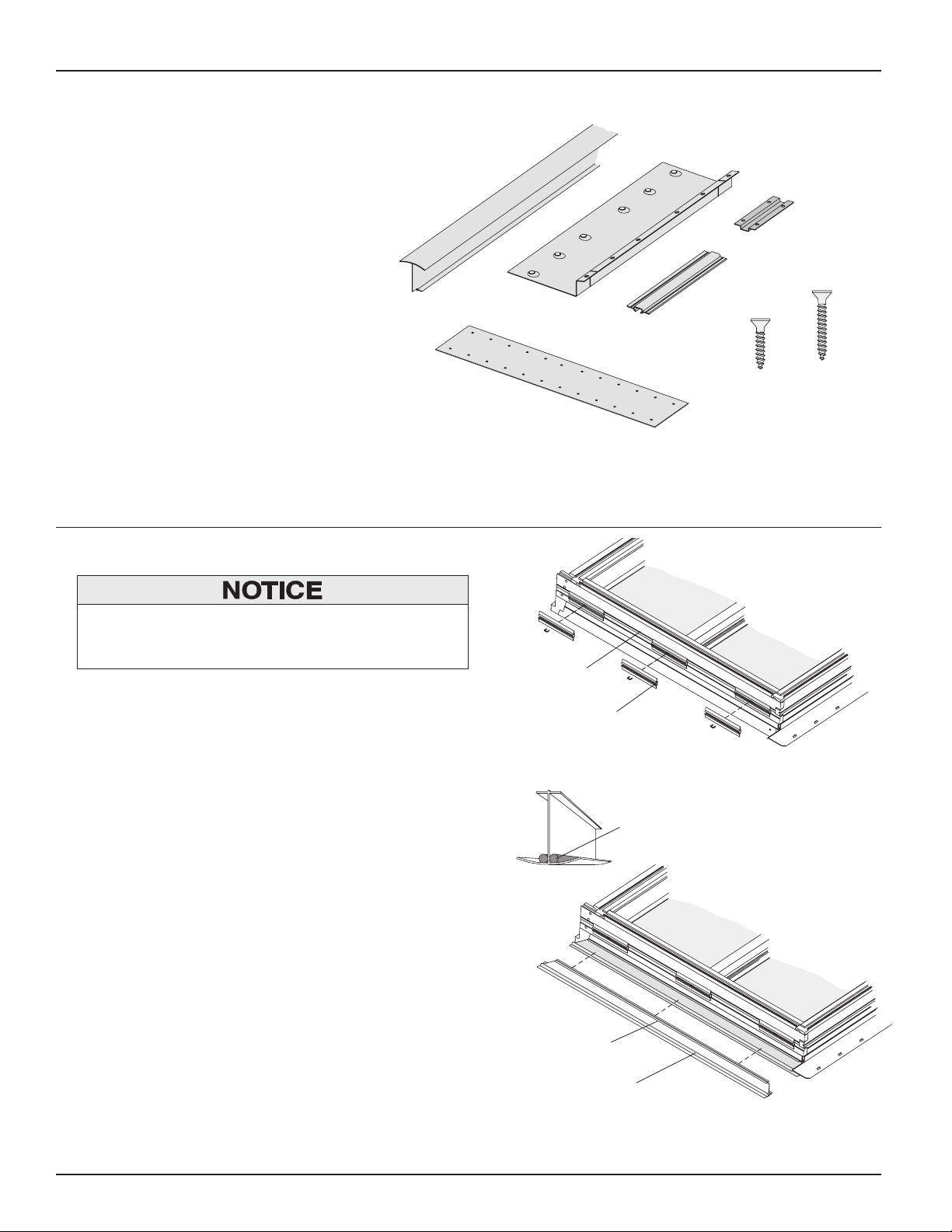

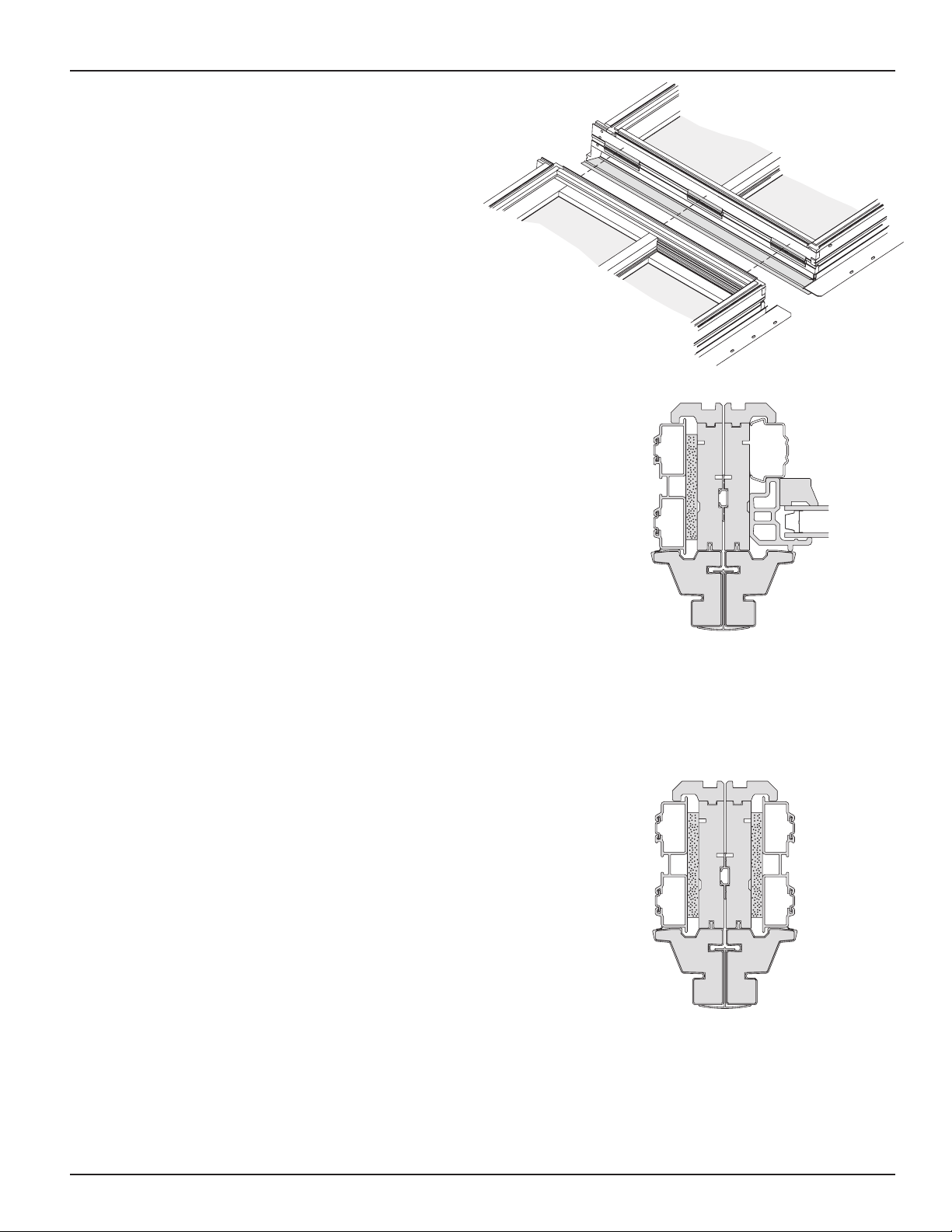

Non-Reinforced Joining Guide (Vertical)

Windows and doors can be heavy.

Use safe lifting techniques and a

reasonable number of people with

enough strength to lift, carry and

install window and door products

to avoid injury and/or product

damage.

Use caution when working at elevated

heights and around unit openings. Follow

manufacturer’s instructions for safe use of

ladder and/or scaffolding. Failure to do so

may result in injury or death.

Follow manufacturer’s

instructions for safe operation

of hand/power tools. Always

wear safety glasses. Failure to

do so may result in injury and/

or product damage.

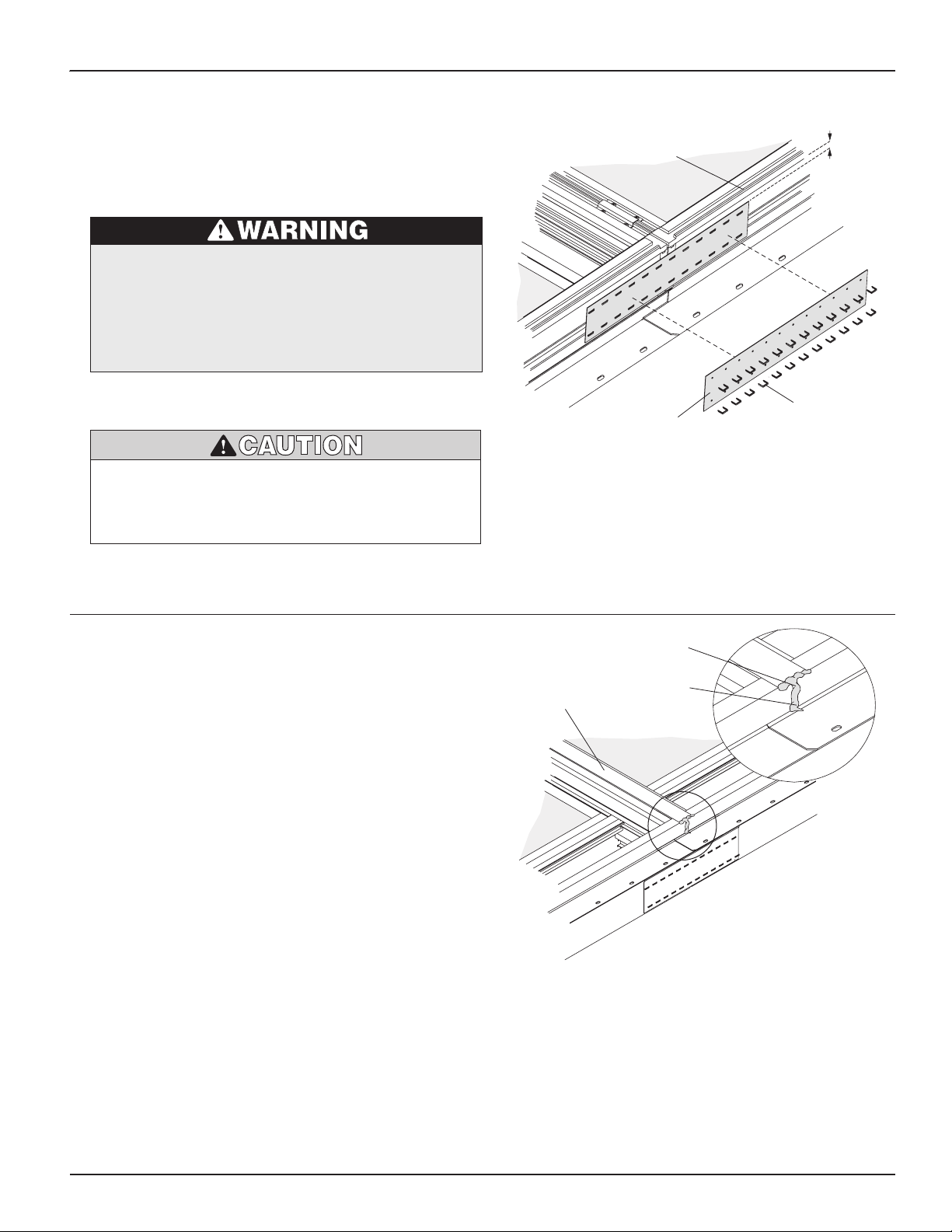

Every assembly and installation is different (windloads, structural support, etc.). Andersen strongly recommends

consultation with an Andersen supplier or an experienced contractor, architect, or structural engineer prior to the

assembly and installation of any Andersen product. For installation methods not covered in this guide, (i.e. through

jamb) please visit the Architect Detail File on the web (www.andersenwindows.com). Andersen has no responsibility in

regard to the post-manufactured assembly and installation of Andersen products.

Congratulations! You have just purchased one of the many fine Andersen®products. Proper assembly, installation and

maintenance are essential if the benefits of your Andersen product are to be fully attained. Therefore, please read and

follow this instruction guide completely. If your abilities do not match this procedure’s requirements, contact an

experienced contractor. You may direct any questions about this or other products to your local Andersen dealer, found

in the Yellow Pages under “Windows” or call Andersen WindowCare®service center at 1-888-888-7020 Monday through

Friday, 7 a.m. to 7 p.m. Central Time and Saturday, 8 a.m. to 4 p.m. Central Time. Thank you for choosing Andersen.

• Andersen®Installation Flanges DO NOT take the place of standard window and door flashing. Unit must be properly

flashed and sealed with sealant, and full width drip cap for protection against water and air infiltration. Use

non-reflective flashings. Highly reflective flashing tapes can raise the surface temperature of the vinyl to the point

where vinyl deformation and product damage may occur.

• Donotapplyanytypeoflmtoglass.Thermalstressconditionsresultinginglassdamagecouldoccur.

• Useofmovableinsulatingmaterialssuchaswindowcoverings,shutters,andothershadingdevicesmaydamage

glass and/or vinyl. In addition, excessive condensation may result causing deterioration of windows and doors.

Unless specifically ordered, Andersen windows and doors are not equipped with safety glass, and if broken, could

fragment causing injury. Many laws and building codes require safety glass in locations adjacent to or near doors.

Andersen windows are available with safety glass that may reduce the likelihood of injury when broken. Information

on safety glass is available from your local Andersen dealer.

“Andersen” and all other marks where denoted are trademarks of Andersen Corporation. ©2003-2007 Andersen Corporation. All rights reserved.

Non-Reinforced Joining Guide (Vertical)

for Andersen®400 Series Tilt-Wash Double-Hung, Picture,

and Transom Windows

0004372 BB Revised 12/13/07

1