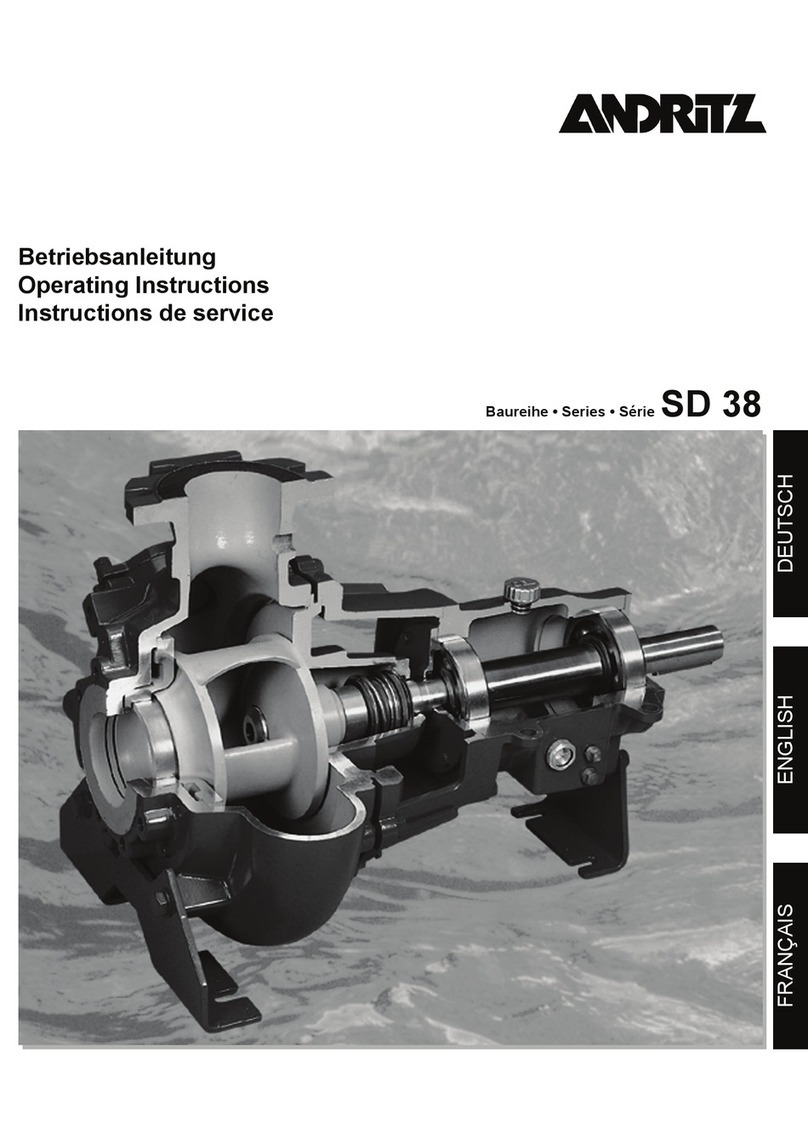

Fan Pump, FP series

Erection Work, Operating and Maintenance Instructions

Rev.0, Printed:2002.03.04TABLE OF CONTENTS Page 2 of 4

#455856 v1 - INHALTSVERZEICHNIS

4 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . 1

4.1 Field of application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4.2 Main components of fan pump . . . . . . . . . . . . . . . . . . . . 2

4.3 Type specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3.1 Applicable standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3.2 Model designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.4 Application limiting values . . . . . . . . . . . . . . . . . . . . . . . 8

4.5 Technological Description. . . . . . . . . . . . . . . . . . . . . . . 12

5 ERECTION WORK and TRANSPORT . . . . . . . 1

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

5.2 Safety regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

5.3 Haulage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

5.4 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.5 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.5.1 Erection of the fan pump . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.5.2 Pipework . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.6 Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.7 Cold test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

6.2 Safety regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

6.3 Prerequisites for start-up. . . . . . . . . . . . . . . . . . . . . . . . . 2

6.4 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6.5 Certificates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

7 OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

7.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

7.2 Safety regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

7.3 Control via DCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

7.4 Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

7.5 Checks after initial start-up . . . . . . . . . . . . . . . . . . . . . . 3

7.6 Normal operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

7.7 Fan pump requirements

(delivery head and flow rate) 5

7.8 Stopping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

7.9 Operating malfunctions and troubleshooting . . . . . . . . 7