Medium-consistency pump - MC

STANDARD, C-01-000000

Rev. 0, 2010.02.09 TABLE OF CONTENTS Page 1 von 4

GRZ-2836263-v1-Table_of_contents.FM

TABLE OF CONTENTS

1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Standards and guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 How to use the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Warranty and guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.5 Manufacturer's name and address . . . . . . . . . . . . . . . . . . . . 4

1.6 Copyright . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.1 General safety regulations . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.2 Danger and warning signs . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.3 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.4 General remarks on machine/plant safety . . . . . . . . . . . . . 2

2.5 User's obligations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.6 General obligations of personnel . . . . . . . . . . . . . . . . . . . . . 5

2.7 Safety devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.8 Safety at the machine installation site . . . . . . . . . . . . . . . . . 9

2.9 Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.10 Noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.10.1 Noise Levels (dB). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.11 Electrical equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.12 Fluids, (liquids, gases, vapour or smoke) . . . . . . . . . . . . . 11

2.13 Welding work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.14 Hydraulic and pneumatic equipment . . . . . . . . . . . . . . . . 13

2.15 Oils and greases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.16 Chemicals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.17 ATEX directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.18 Work in enclosed vessels and in confined spaces. . . . . . 17

2.19 Permit for work in enclosed / confined spaces . . . . . . . . 20

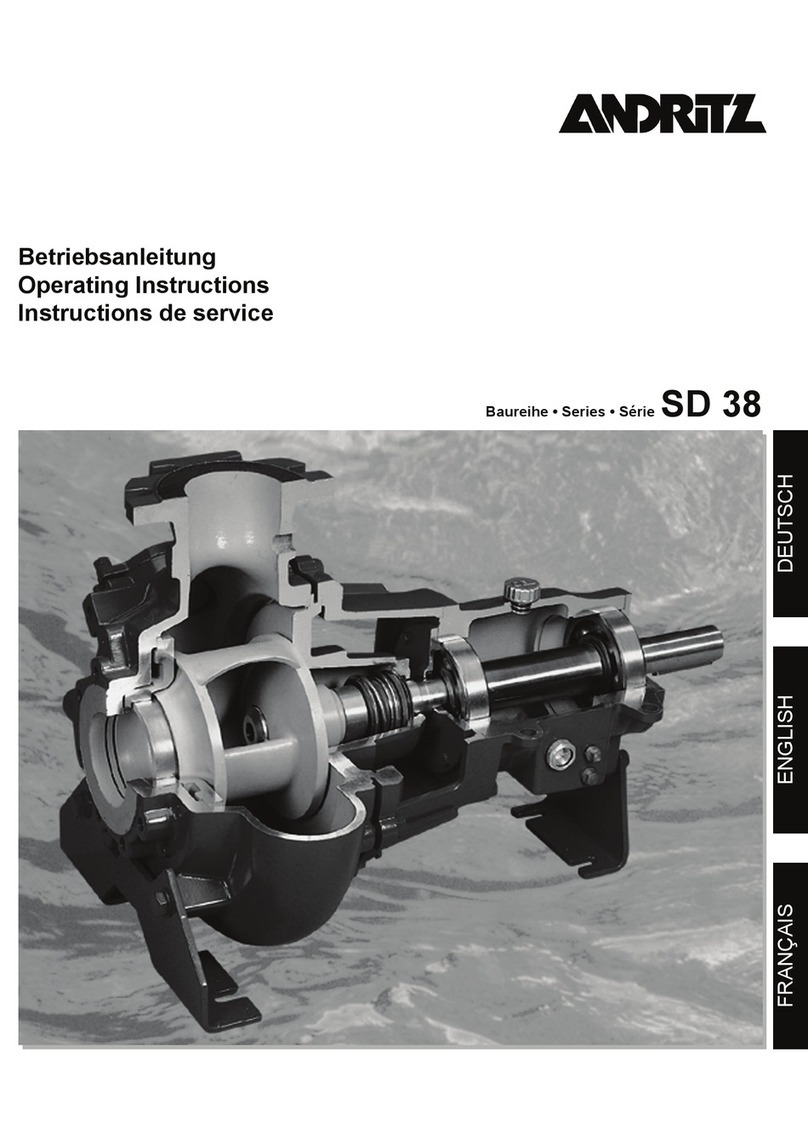

3 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3.1 Field of application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

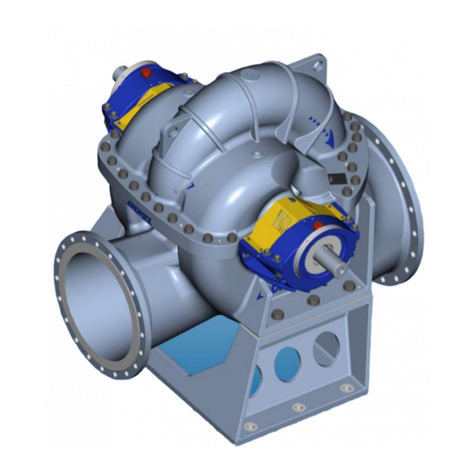

3.2 Main components of the medium-consistency pump . . . . 2

3.3 Centrifugal pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.4 Degasser/ Control cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.5 Standpipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.6 Type specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13