Programming

General information

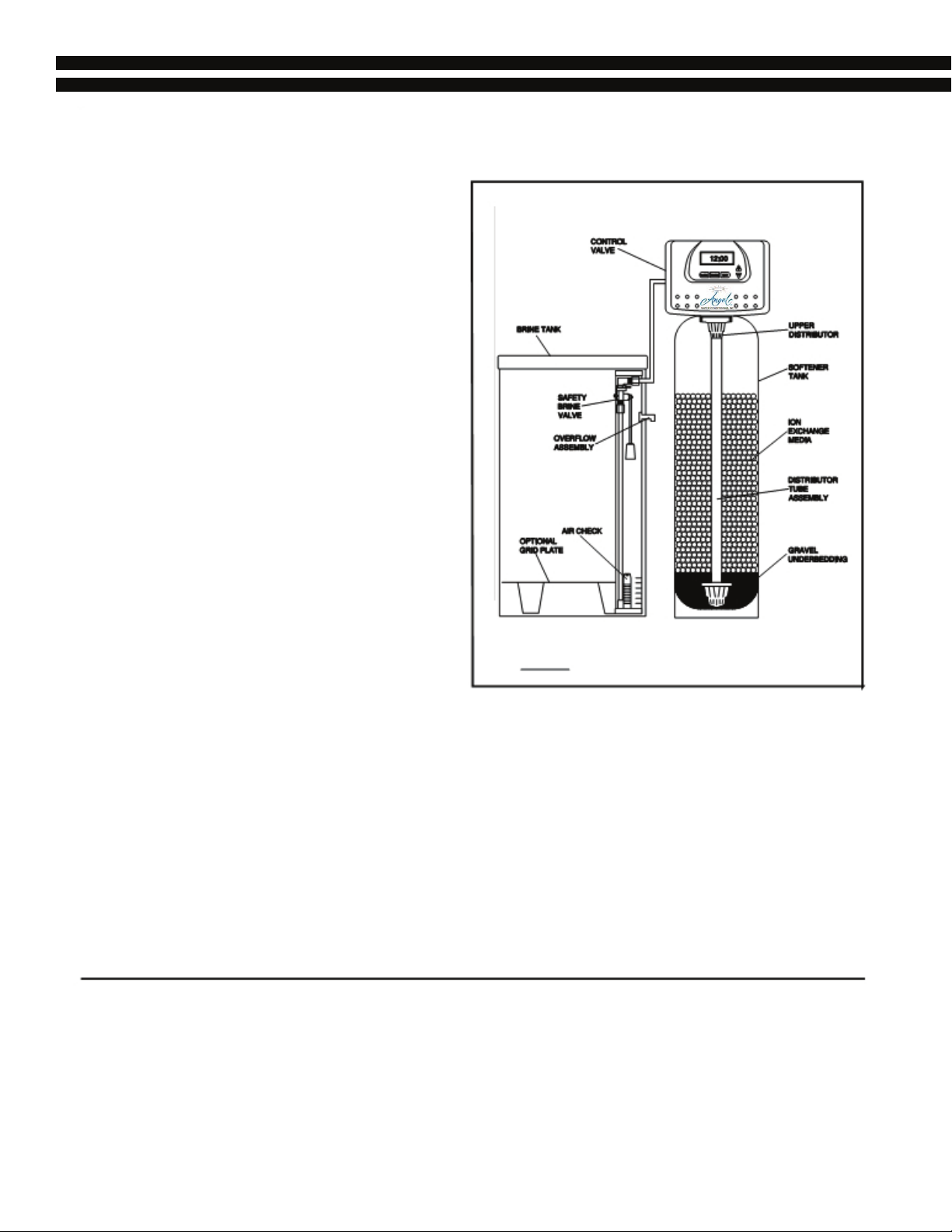

The A3000 control valve is the “brain” of your water soft-

ener. It consists of the valve body and powerhead with solid

state microprocessor.

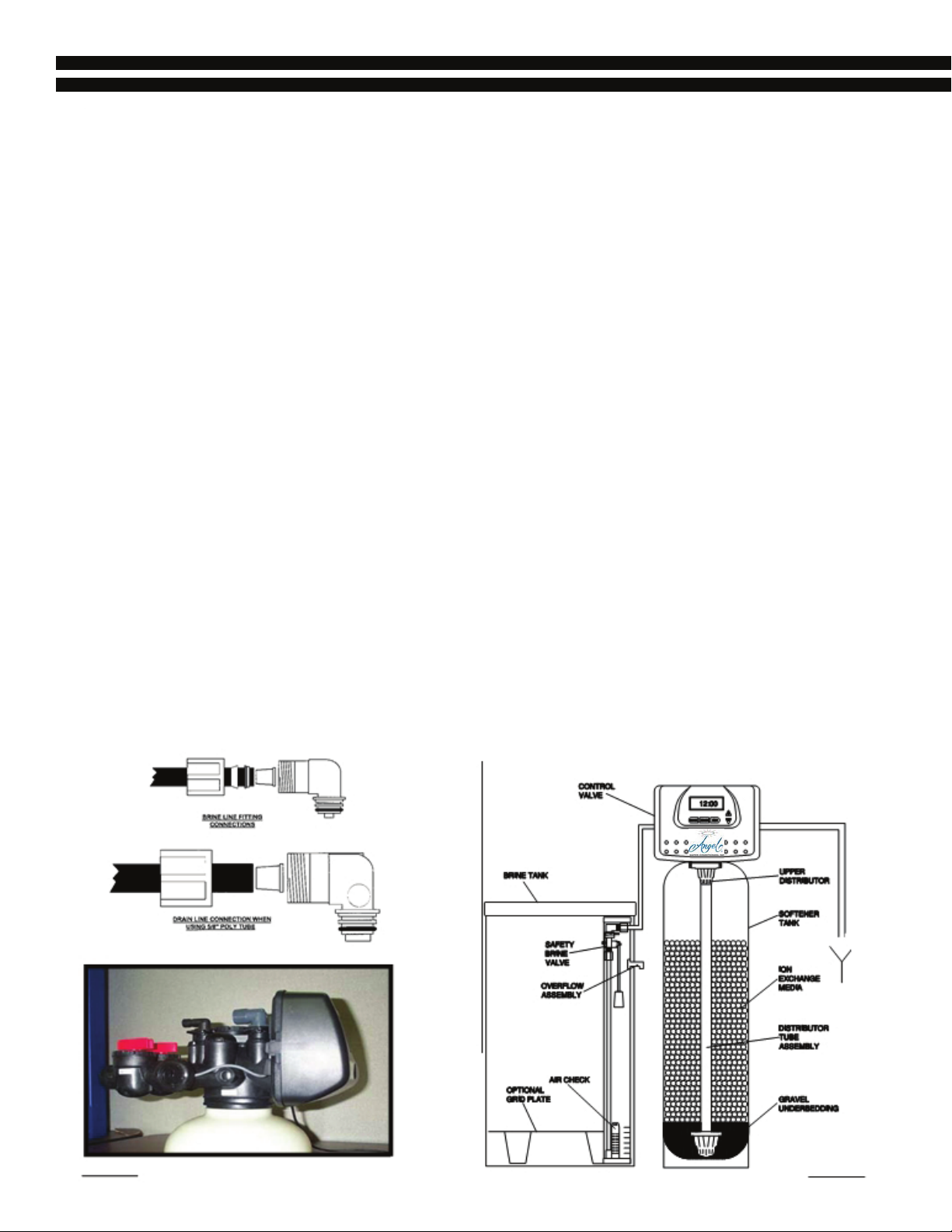

The display panel (see Figure 7) consists of the LCD display

and five push buttons which are used in displaying and program-

ming the water softener settings.

Initial Start Up

The initial start up will probably be done by the technician install-

ing the softener system. If not, the following instructions will step

you through the process.

1. Complete all plumbing connections: inlet, outlet, drain

line and brine line. Do not add salt at this time.

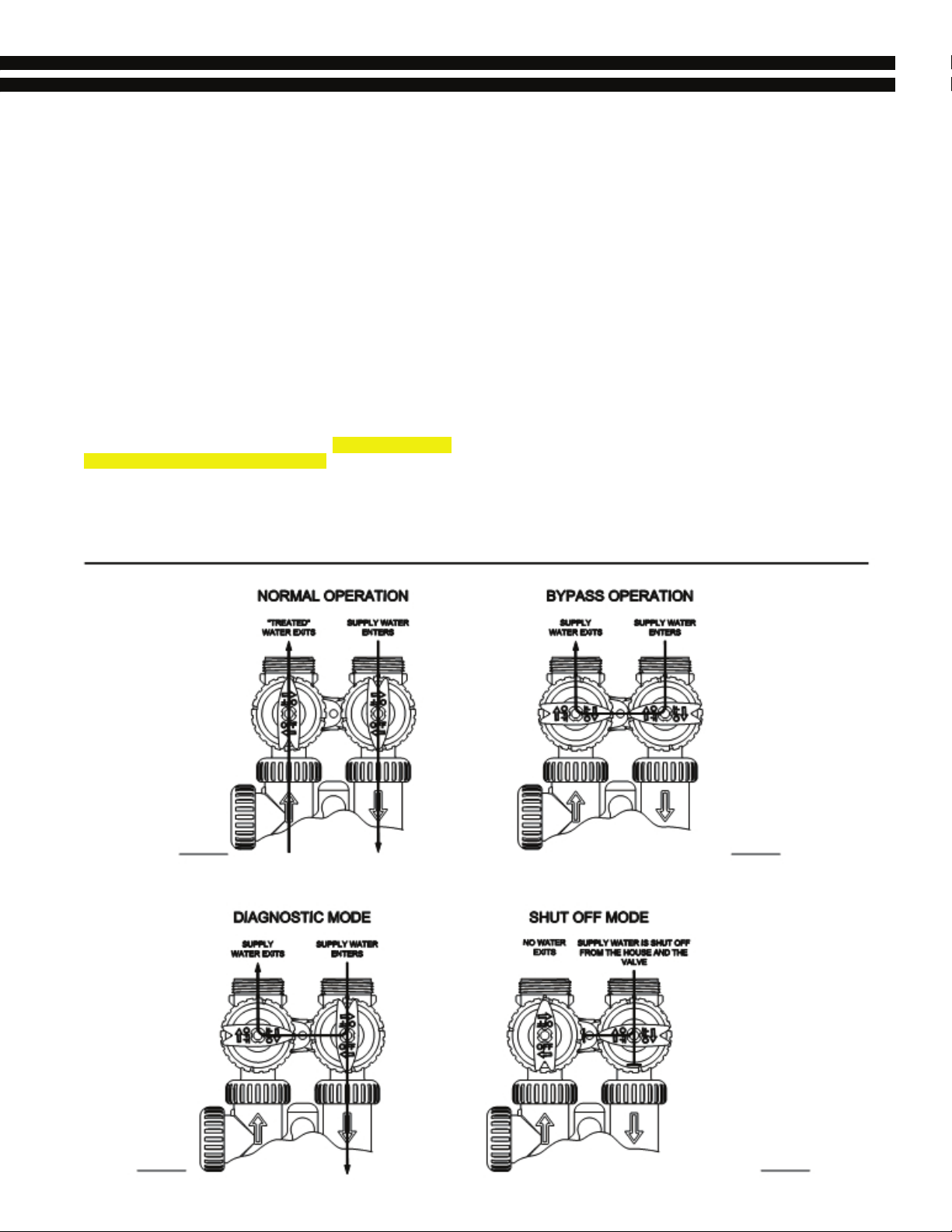

2. Place the bypass valve in the bypass position. (See

figure 3 page 5) Turn on the main water supply. Open

a cold soft water faucet to flush the piping of any air

and/or foreign material. Run until the water is clear.

3. Manually add 6 inches of water to the brine tank.

4. Now plug the transformer into a 110-volt receptacle. (Be

certain the outlet is uninterrupted.) Within 5 seconds the

control will automatically align itself into the softening

mode and display will automatically alternate between

time of day, gal/min and gallons remaining. (Figure 8,

page 7).

5. Set the time of day by pushing clock button (figure 9,

page 8) and using and buttons.

6. Push REGEN button and hold it down for 3 seconds.

The system will advance to the “First” position. (Note:

Depending on how the system is programmed it could

read backwash, rinse, brine or fill). Keep pushing

REGEN button until “Rinse” shows in the lower right

hand corner of display. Slowly place the by-pass into

the “diagnostic mode” (see fig 4, page 5). Run water

to the drain until it runs clear. Return the by-pass valve

to the by-pass position (fig 3, page 5). Push REGEN

button until “unit is back to softening mode.

7. Once again, push REGEN button and hold down for

3 seconds. Keep pushing REGEN button until “Back-

Figure 7

wash” appears. Slowly place the by-pass valve into the

“Diagnostic Mode” 1/2 way. Allow water to slowly fill

the mineral tank. When a solid stream of water starts

coming out of the drain line, open the by-pass inlet

valve all the way and allow to run out the drain until

water clears. Then slowly place the by-pass into the

“normal operation” mode by opening the outlet side of

by-pass valve, figure 2, page 5.

8. Press the REGEN button until LED display says “BRINE”.

Loosen the brine line from the top of the safety brine

valve in the brine tank. Place finger over the end of the

tube to check for suction. If no suction, see trouble-

shooting guide. (See #11, Page 17) If proper suction,

reattach brine tube to safety brine valve, and allow it to

draw water down to the bottom of the air check, (figure

6b, page 6).

9. Press REGEN button again until LED once again dis-

plays “BACKWASH”. Keep in backwash until water

once again runs clear at the drain.

10. Press REGEN button again until “RINSE” is displayed.

Allow rinse cycle to run its full course. While the rinse

cycle is finishing, this would be a good time to load your

brine tank with salt.

11. Once the rinse cycle has finished the softener control

will return to the softening cycle. The LED screen will

scroll between “TIME/GPM/GALLONS REMAINING”.

12. Next set your softeners water hardness, days override and

regeneration time settings (see figure 10a, page 8).

Your programming is now complete.

User displays/settings

General Operation

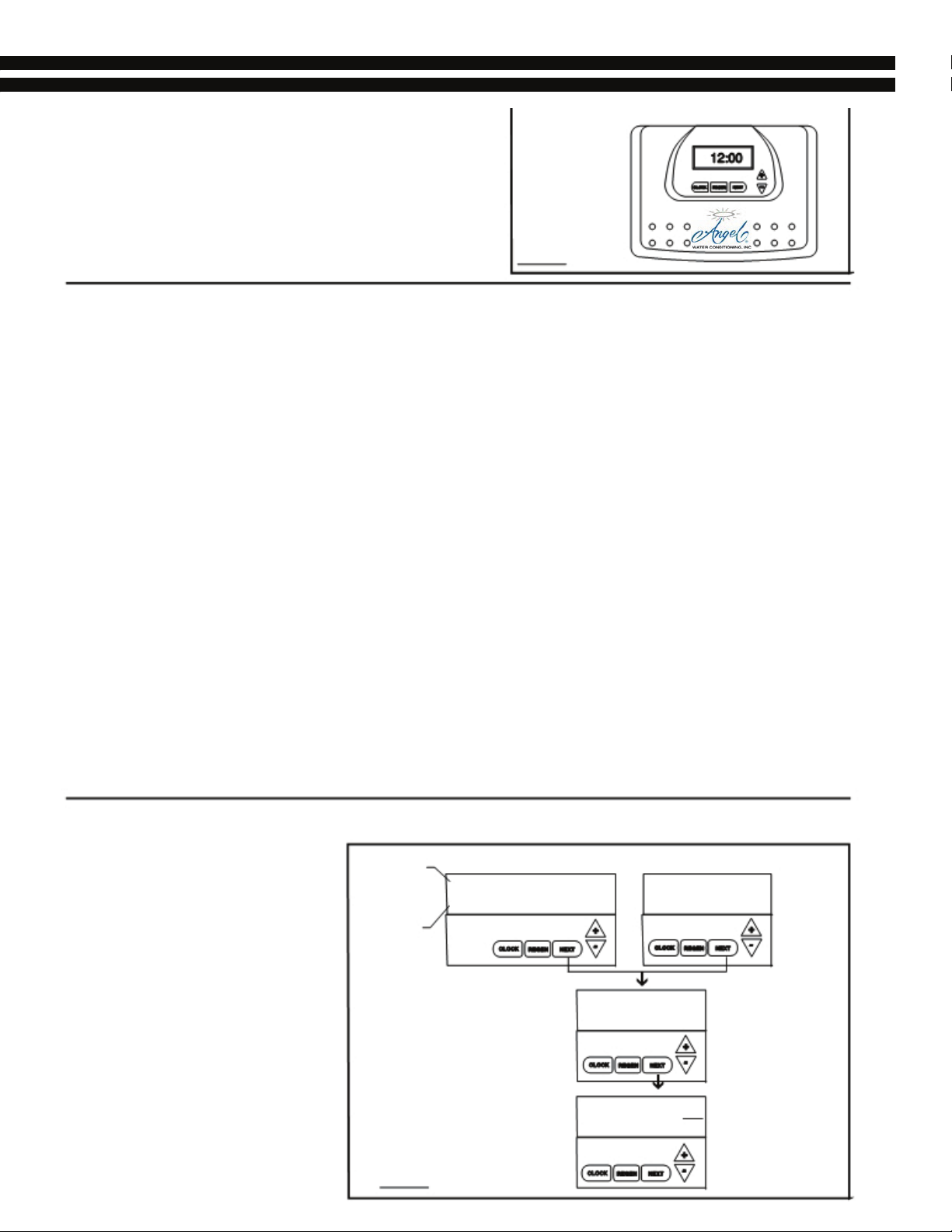

When the system is operating, one of three

displays may be shown. Pressing NEXT will

NORMAL OPERATION SCREENS

SOFTENING or

FILTERING SOFTENING CAPACITY REMAINING

Flashes when the

REGEN GAL

USER 1

REMAINING Typical user

display.

alternate between the displays. One of the

displays is the current time of day. The second

display is one of the following: days remain-

ing or gallons remaining. Days remaining is

the number of days left before the system

goes through a regeneration cycle. Capacity

turbine is rotating. TODAY

REGEN TODAY

will show if REGEN

button pushed once.

650

DAY

6

Shows capac-

ity or days

remaining

before a re-

generation.

remaining is the number of gallons that will "Tonight" or 0 days remaining = within the next 24 TIME

PM USER 2

be treated before the system goes through a

regeneration cycle. The third display is current

flow in gal/min. The user can scroll between

the displays as desired by pushing NEXT or

display will scroll automatically.

When water is being treated (i.e. water is flow-

hours. This determination is made at the sched-

uled regen time for meter initiated regenerations

& at midnight for day initiated regenerations.

User screens will continuously scroll, switching

views every 3 seconds. If the screens are manu-

ally scrolled, this screen will remain constant for

5 minutes then continue to scroll. The conditional

screens will take precedence over the scrolling

and the conditional conditions will apply.

6:35

SOFTENING

GAL

Displays current time.

USER 3

ing through the system) the word "Softening"

or "Filtering" flashes on the display if a water

meter is installed.

7

6.8

Figure 8

MIN Displays present flow

rate.