10 11ToughLift®Material Lifts Maintenance ManualToughLift®Material Lifts Maintenance Manual

Section 2 – Safety During Maintenance /continuedSection 2 – Safety During Maintenance

WARNINGS

Failure to adhere to the Safety Rules below and the additional Safety Rules outlined in the

ToughLift®Material Lifts Instruction Handbook will result in serious injury or death.

Many of the hazards identied in the Instruction Handbook are also safety hazards when

maintaining or repairing a machine or accessory.

Any person working on or around a machine must be aware of all the potential safety hazards.

Be aware of the safety colour coding system in Section 9 of this manual. This system is used in

the Instruction Handbook, in this Maintenance Manual, and on the decals on the ToughLift®

Material Lifts and accessories.

NEVER undertake maintenance of a ToughLift®

Material Lift unless you are trained, qualied, and

authorised to do so.

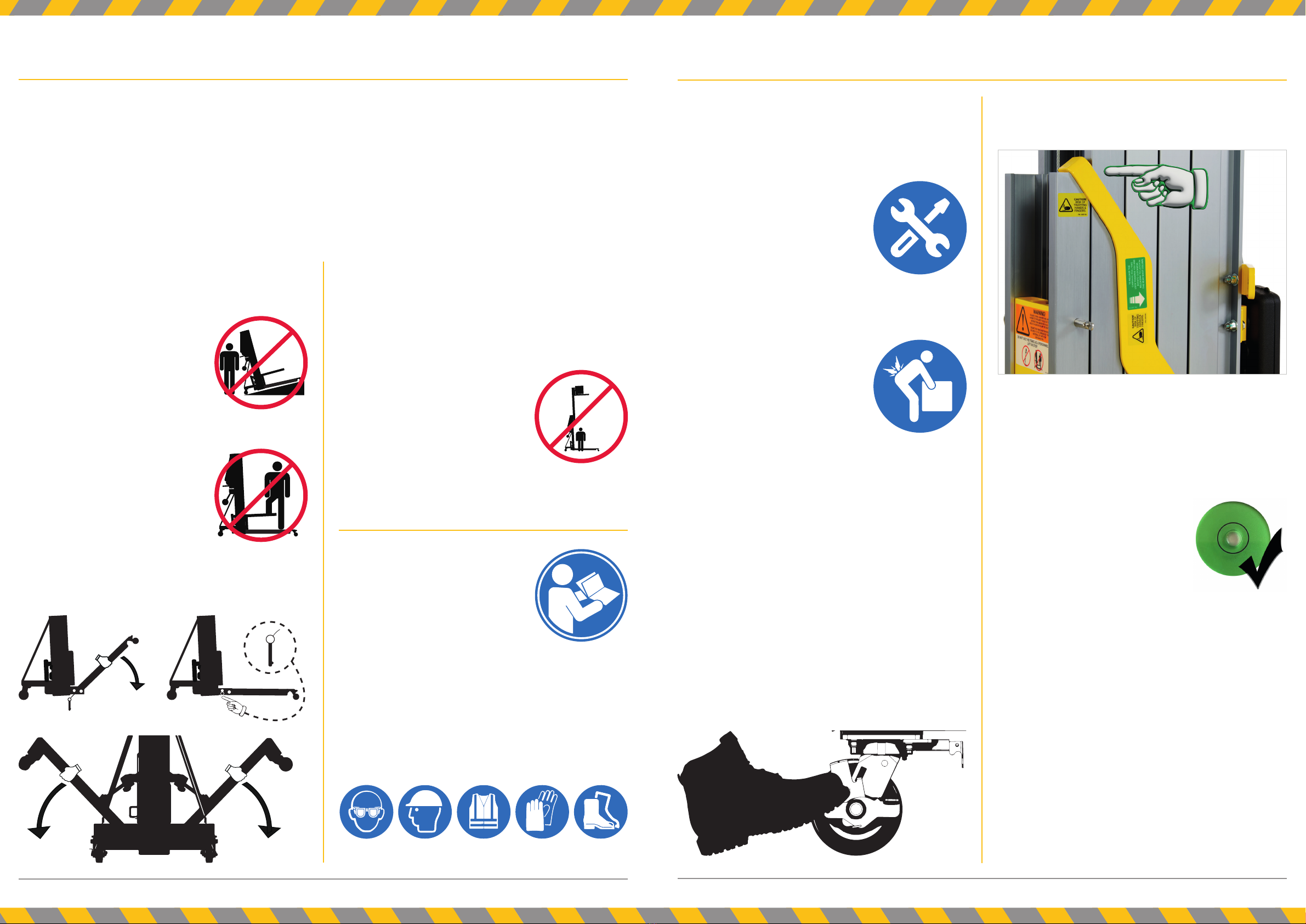

NEVER stand below a ToughLift®

Material Lift on an incline when

moving the machine around a

worksite or workshop.

NEVER interfere with the mechanical

safety devices in the mast assembly and winch.

NEVER stand on, step on, or climb

on the mast, Standard Forks, Pipe

Cradle, Extension Forks,

Load Platform, or Boom of a

ToughLift®Material Lift. This is

not a personnel lift.

NEVER raise the mast (loaded or unloaded)

unless the front legs and stabilisers (if the model

being used is equipped with stabilsers) are

deployed and locked in position.

ALWAYS ensure the safety of persons that may

enter the area around the machine, and keep

vehicles clear of the work area i.e., cordon off the

area to prevent persons and vehicles entering the

danger area.

ALWAYS ensure that you have

prepared the necessary work

area, tools, and components

required for the work being

undertaken on the ToughLift®

Material Lift.

ALWAYS keep work surfaces clean and free of

debris that could get into the components of the

machine and cause damage.

ALWAYS use proper lifting

techniques to tip the machine,

or to t or remove load handling

attachments to or from the

carriage.

ALWAYS ensure that any forklift, overhead crane,

or other lifting or supporting device has an

adequate safe working load or working load limit

to support and stabilise the weight to be lifted.

Only use adequately rated chains or straps that

are in good condition.

ALWAYS be aware of potential crushing hazards

such as moving parts, and free swinging or

unsecured components when lifting or placing

loads.

ALWAYS check that the LOLER certication of

the machine and any removable accessories is

in date before working on the machine (UK only,

regulations in other countries vary).

ALWAYS lock both braked swivel castors when

the machine is stationary.

NEVER raise the mast (loaded or unloaded)

unless all 4 (or 6 if stabilisers are tted) castors

are in touch with the ground.

NEVER move a ToughLift®Material Lift when the

carriage is loaded, whether the mast is lowered

or raised (except for very minor repositioning).

NEVER stand under or allow other

personnel to stand under the

machine when the load is raised.

NEVER use a ToughLift®Material Lift as an

electrical earth when welding structures

alongside it.

ALWAYS read, understand, and

adhere to the Instruction

Handbook located in the

document holder on the back

of the xed mast column before

working on a ToughLift®Material

Lift.

ALWAYS wear suitable personal protective

equipment when undertaking maintenance on a

ToughLift®Material Lift. It is recommended that

you wear suitable eye protection, safety helmet,

high visibility vest, gloves, and safety boots or

shoes with steel toe caps. Always undertake a

risk assessment.

ALWAYS engage the carriage lock when moving

the machine around a worksite or workshop, or

from site to site on a delivery vehicle.

ALWAYS be aware of the following potential

nger trap points when setting up the machine:

2 front leg joints

2 stabiliser leg joints (if tted)

Carriage lock

Carriage

ALWAYS check that the machine

is level before raising the mast by

ensuring the bubble in the spirit

level is within the black circle.

ALWAYS hold the front leg when

the retaining pin is removed as it

will drop.

ALWAYS hold the stabiliser when the lock is

released as it will drop.

ALWAYS grip the winch handles until the winch

brake is locked i.e., when the weight of the load

will not cause the winch handles to turn.

ALWAYS engage the ratchet system before

releasing the winch handles by turning the winch

handle ¼ turn clockwise (away from you/raising

the load) to ensure that the ratchet/brake system

is engaged before winding up the mast to the

desired working height.

ALWAYS ensure that xings intended for one

time use e.g., self-locking nuts, cotter pins, roll

pins etc. are not reused.