SPIDER SC1000-RE User manual

Hoist Operation Quick Reference

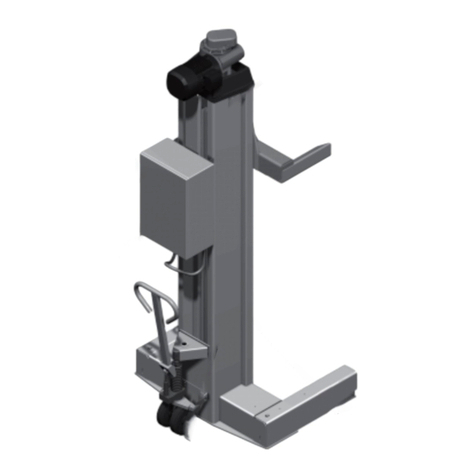

SC1000-RE Hoist

READ THE OPERATORS MANUAL BEFORE USING THIS QUICK REFERENCE

Normal Operation

• Conrm battery connection by verifying the UP operation Button is illuminated green. Verify battery charge level is

sucient for anticipated use 12 . Push in the UP operation button to display battery charge level.

• For routine travel in the UP direction, push in the UP operation button.

• For routine travel in the DOWN direction, push in the DOWN operation button.

• Both buttons are spring-loaded and will return to the OFF position AND apply the brake when released.

• After releasing the buttons, if the hoist does not immediately stop, press the emergency stopAND the overspeed

brake test button.

Unplug the power supply cable.

• Perform daily testing and inspection (see over) to ensure safe and correct operation. DO NOT use the hoist for

lifting until it has successfully completed the daily tests.

Reeving

• Push the primary suspension wire rope through the primary

suspension wire rope insertion point approximately

15 inches.

• Operate the hoist in the UP direction while pushing the rope

into the hoist.

• Ensure the wire rope runs freely through the Primary Wire

Rope Exit Guide.

• If the hoist is equipped with an optional secondary

suspension wire rope, push the secondary suspension wire

rope through the secondary suspension wire rope insertion

point until it exits the hoist 11 .

• Attach a 25 lb (11.5 kg) weight to the end of the secondary

wire rope to assist secondary wire rope travel.

723547-1 Revision: A

Overspeed

Reset Knob

UP Operation Button

and Power On (Green

Light)

Emergency Stop

(Power Supply Cut-off)

Primary Wire Rope

Insertion Point

Overspeed

Brake Test

Button

Primary Wire Rope

Exit Guide

DOWN Operation Button

and Overspeed Brake Trip

Indicator Light (Red Light)

Carrying Handle

Hour Meter and Battery

Charge Level Indicator 12

Power Supply

Cable

Remote Receptacle

Attach hoist to

stirrup bar

Optional Wire Rope

Insertion Point for

Secondary Wire Rope

Operating Instructions

Manual and Schematic

Emergency Descent

Lever Insertion Point

Motorshaft Access Plug

Model Designation

and Serial Number

Secondary Wire Rope

Exit Spring 11

(Optional Feature)

Optional Secondary

Suspension Wire Rope

Insertion Point

Primary Suspension Wire

Rope Insertion Point

Emergency Descent

Lever Storage

Dereeving Secondary Suspension Wire Rope

• In order to remove the optional secondary suspension wire rope, there must be no slack on the primary suspension

wire rope and the platform must be supported on a stable surface.

• Remove the counterweight from the end of the secondary suspension wire rope.

• Pull the secondary suspension wire rope out of the hoist by hand.

• If necessary, the primary suspension wire rope can now be removed from the hoist.

Dereeving Primary Suspension Wire Rope

For hoists equipped with the optional secondary wire rope, the secondary wire rope must be removed before

the primary wire rope is removed.

• WARNING!WARNING! To prevent hoists and platform from tipping and avoid injuries, ensure that the platform is properly

supported on a stable, at surface before putting slack on the primary suspension wire rope.

• Push in the DOWN operation button to wind the primary suspension wire rope out of the hoist. To remove

the last 15 inches (40 cm) of wire rope, if necessary, grab the wire rope above the primary suspension wire rope

insertion point, hold the overspeed brake reset knob in the reset position (vertical) and slowly pull the primary

suspension wire rope out of the hoist.

Daily Testing and Inspection

• Before operating the hoist, inspect the following:

▫ Wire rope, Power supply, Rigging, Platform, and Hoist

▫ All parts are present, in proper working order, and are not damaged.

▫ Bolts, nuts, and clamps are well secured.

▫ Ensure the hoist is secured to the stirrup with SAE Grade 5 fasteners and lock nuts that are properly installed.

• In a dirty environment that contains epoxy, paint, cement, sand blast residue, or corrosive material, inspect the

operation of the overspeed brake several times a day. Protective hoist covers are recommended. Contact your

supplier.

Battery charge level

• The battery will recharge as the hoist is operated in the down direction.

• Use the Battery Charge Level Indicator 12 to determine if there is sucient charge for anticipated use.

• If power is lost while suspended, use the emergency decent lever to lower the platform.

Test the Overspeed Brake

• While powering the hoist UP and DOWN

approximately 3 feet (1 meter), look through the

window into the overspeed compartment to see

whether the ywheel is turning.

Flywheel

• Dereeve the wire rope:

• Re-insert the wire rope about 12" (30 cm) into

the hoist.

• Holding the wire rope rmly, pull it out quickly. If

the brake is working correctly, it will grab and hold

the wire rope in less than 4" (10 cm). The DOWN

button will light up REDRED to indicate the overspeed

brake has activated and the DOWN circuit has been

interrupted.

• Repeat this test at least 3 times. If the brake does

not work correctly every time, DO NOT USE THE

HOIST. Return the hoist to your supplier.

• Reset the overspeed brake by turning the overspeed

brake reset knob clockwise.

Test the Overspeed Brake Test Button

• Push in the UP operation button and raise the platform approximately 3 feet (1 meter).

• Remove the Emergency Descent Lever from the storage location and insert into brake through the motor fan

shroud .

• Lift the Emergency Descent Lever. As the hoist begins to descend, push the Overspeed Test Button.

• The hoist MUST stop IMMEDIATELY!

Test the Emergency Stop Button

• While running the hoist in either direction, press the red emergency stop button.

• Once the emergency stop button has been pressed, the hoist should not move at all.

• To reset the emergency stop button, pull the button out.

Test the Emergency Descent

• Raise the platform approximately 3 feet (1 meter).

• Remove the Emergency Descent Lever from the storage location and insert into brake through the motor fan

shroud .

• Pull up the emergency descent lever SLOWLY, to make sure the hoist does not overspeed. The platform should

descend at a* slow, controlled speed.

WARNING!WARNING! If the overspeed brake trips while testing the emergency descent, the emergency descent system is not

working properly and THE HOIST SHOULD NOT BE USED.

Other SPIDER Lifting System manuals

Popular Lifting System manuals by other brands

Hinowa

Hinowa LIGHTLIFT 15.70 PERFORMANCE Quick instructions

Ravaglioli

Ravaglioli RAV261-2-L manual

Ravaglioli

Ravaglioli KPN345WE Translation of the original instructions

Southwire

Southwire Sumner GH2T-3 Operator's manual

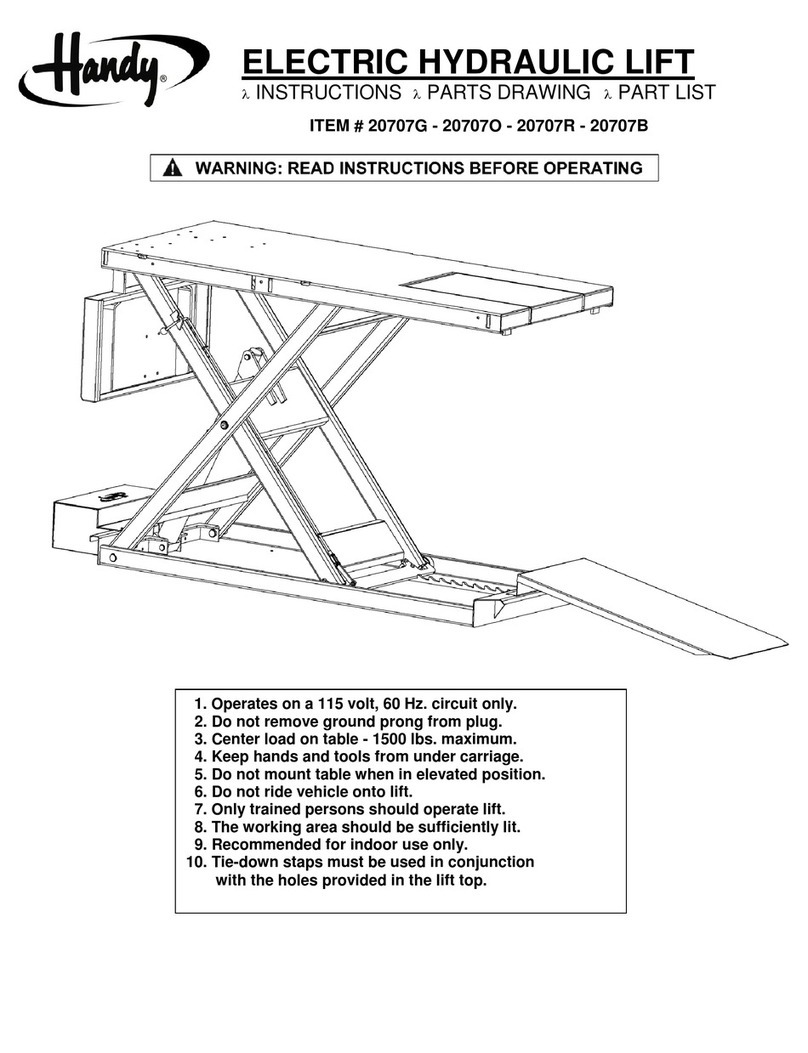

The Handy

The Handy 20707G INSTRUCTIONS, PARTS DRAWING, PART LIST

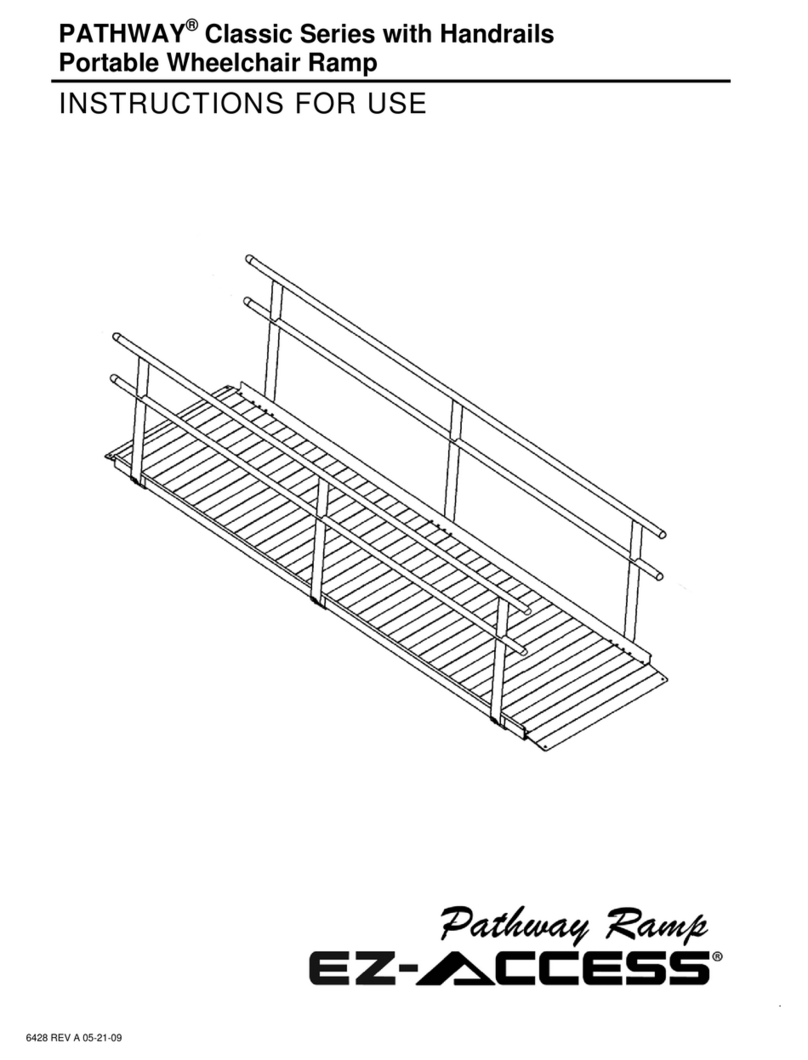

EZ-ACCESS

EZ-ACCESS PATHWAY Classic Series Instructions for use

ALFRA

ALFRA TML 250 Operation manual

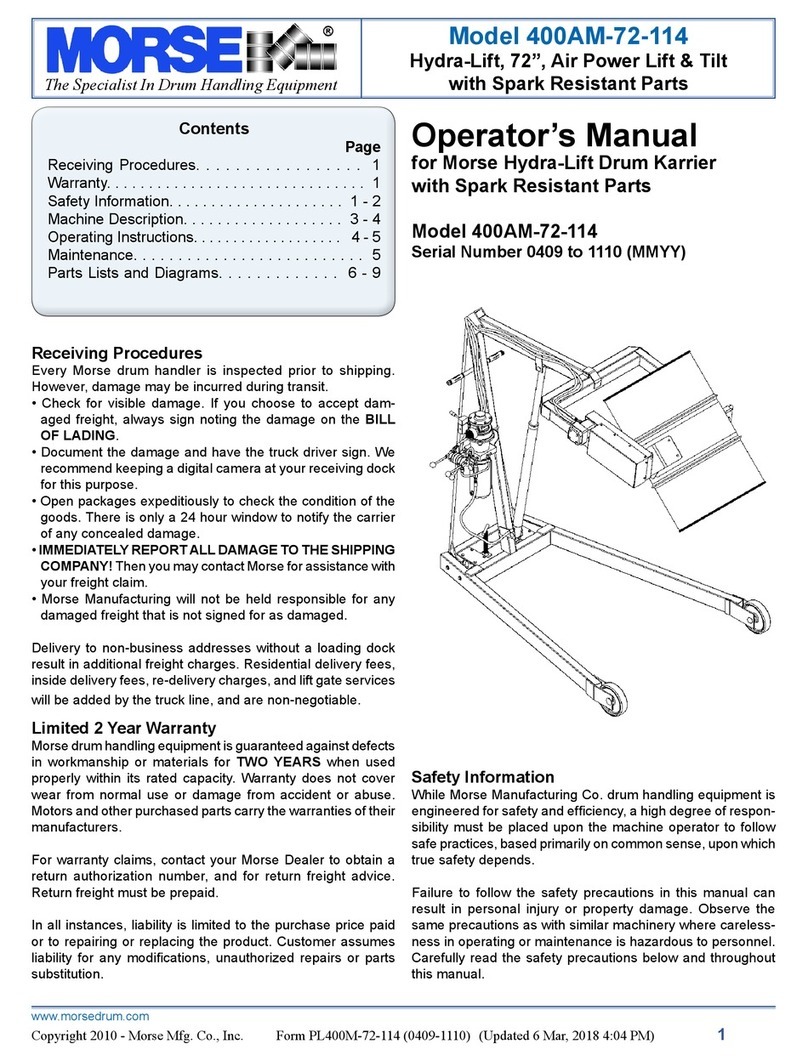

morse

morse 400AM-72-114 Operator's manual

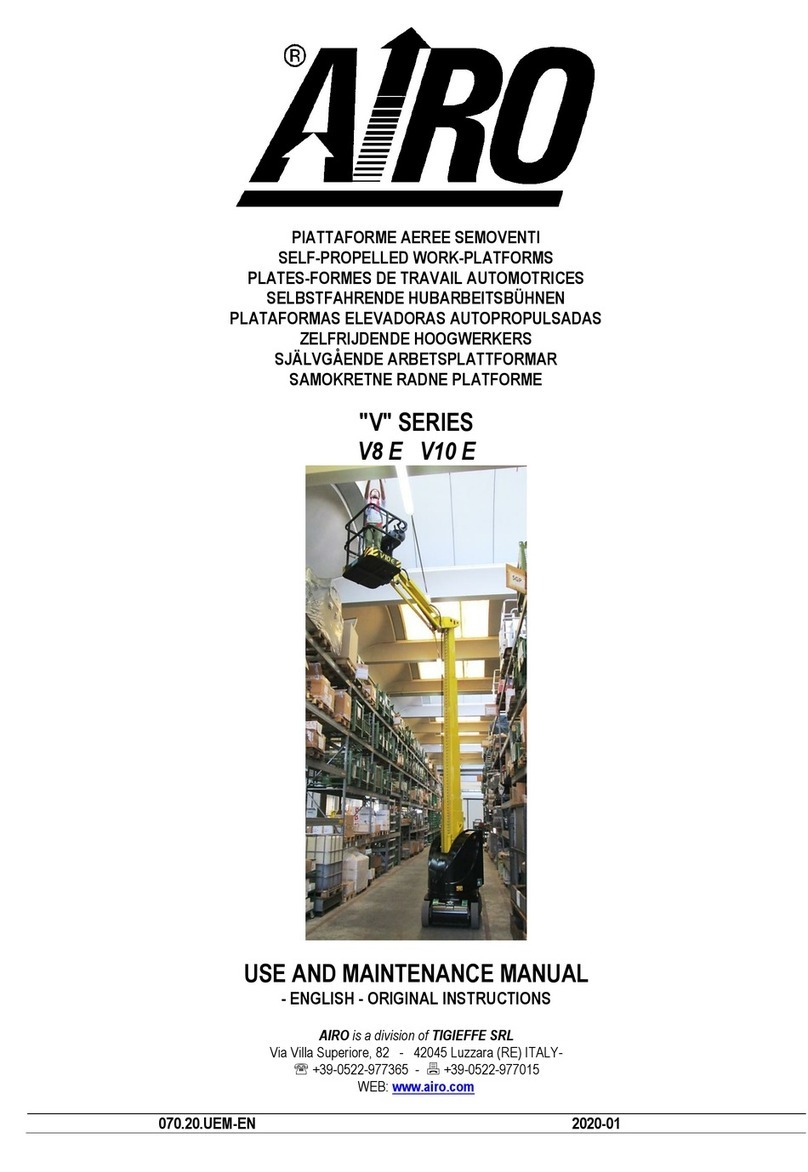

TIGIEFFE

TIGIEFFE Airo V Series Use and maintenance manual

VMB

VMB Pro Lifts TL-063 Operating instructions & user manual

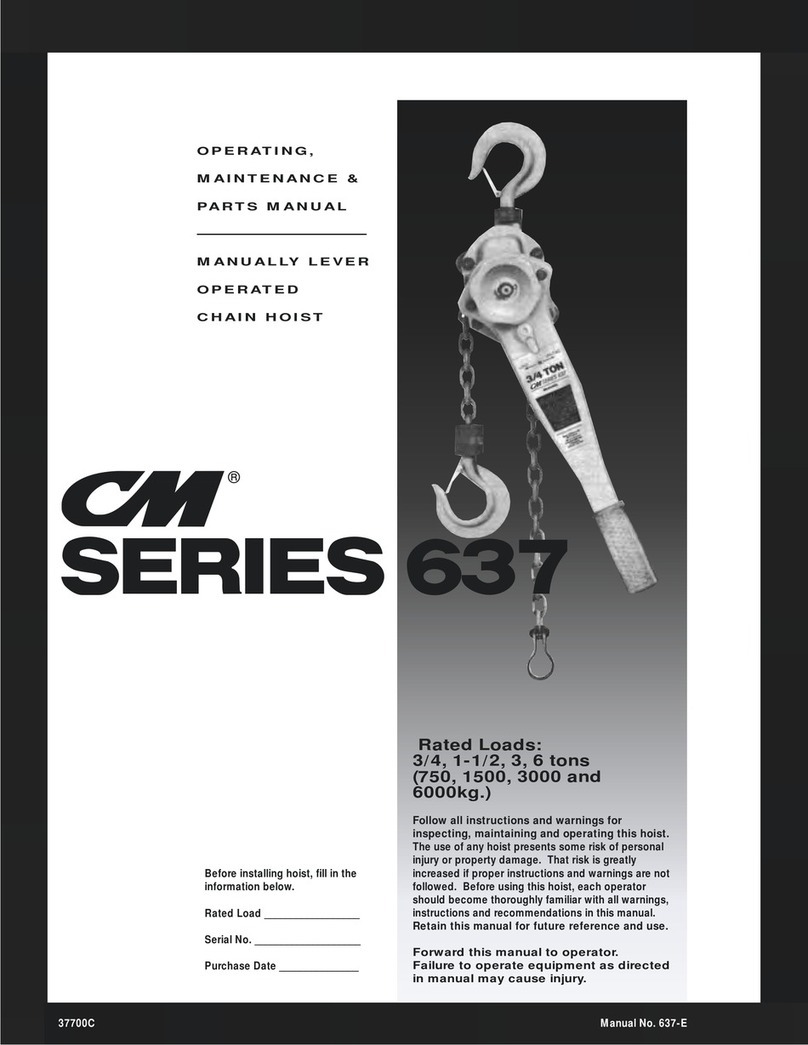

CM

CM 637 Series Operating, Maintenance & Parts Manual

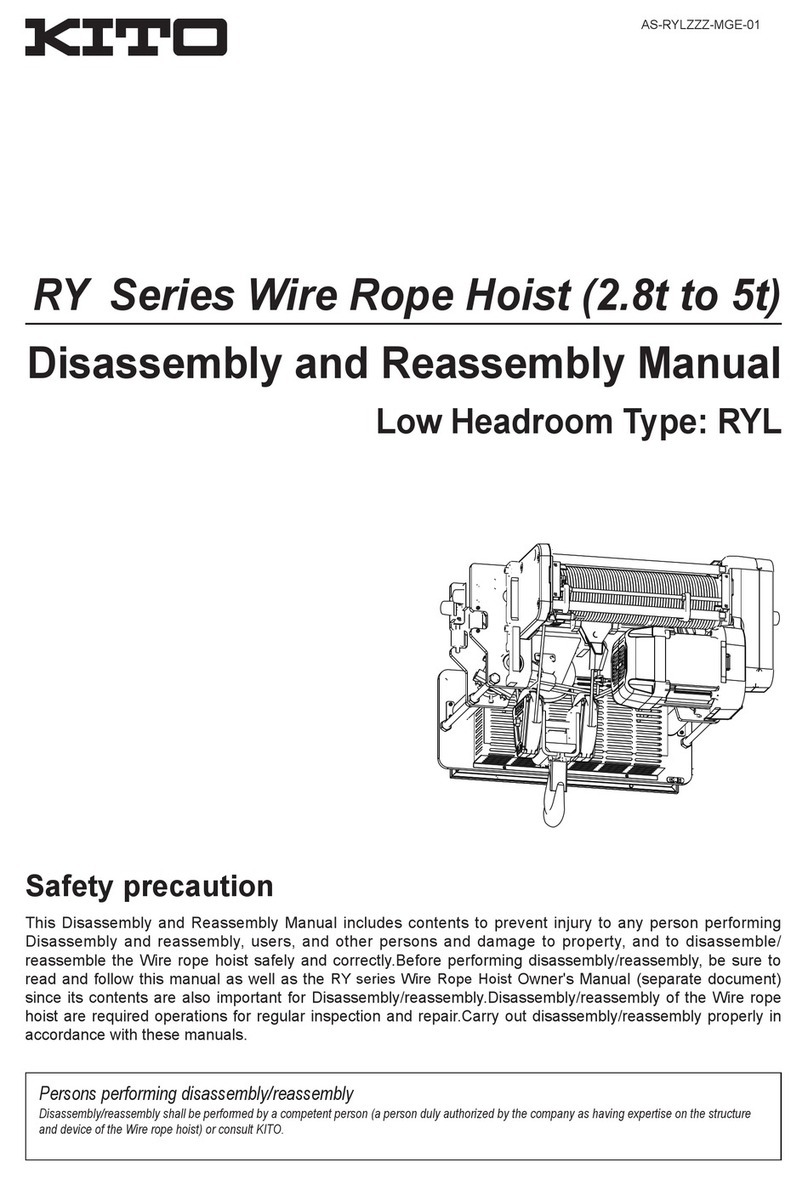

KITO

KITO RY Series Assemble, Disassemble & Troubleshooting Instructions