Page 6 of 13

4.0 OPERATION

WARNING: Tube failure may result in fluid being sprayed from pump. Use appropriate measures to

protect operator and equipment. Tubing should be inspected periodically for tears, cracks, cuts, or

abrasions.

WARNING! Use only factory approved tubing from the designated tubing class. Incorrect tubing can

adversely affect performance or damage the pump.

4.1 Controls

3-Way Rocker Switch – All models are equipped with a 3-way rocker switch mounted on the front

of the pump. The Up and Down positions turn the pump ON in the clockwise and counterclockwise

direction, respectively, and the center position is OFF. Always confirm the switch is in the

designated OFF position before plugging the pump into any power receptacle.

Potentiometer – All models are equipped with a potentiometer on the front of the pump which is

used to regulate pump speed (output) and analogue signal scaling, depending on model.

Mode Switch – For models equipped with a remote operation function, a latching, push-button

switch is located on the back of the pump which activates and deactivates external control.

OUT=LOCAL; IN=EXTERNAL.

4.2 Adjusting Flow Output

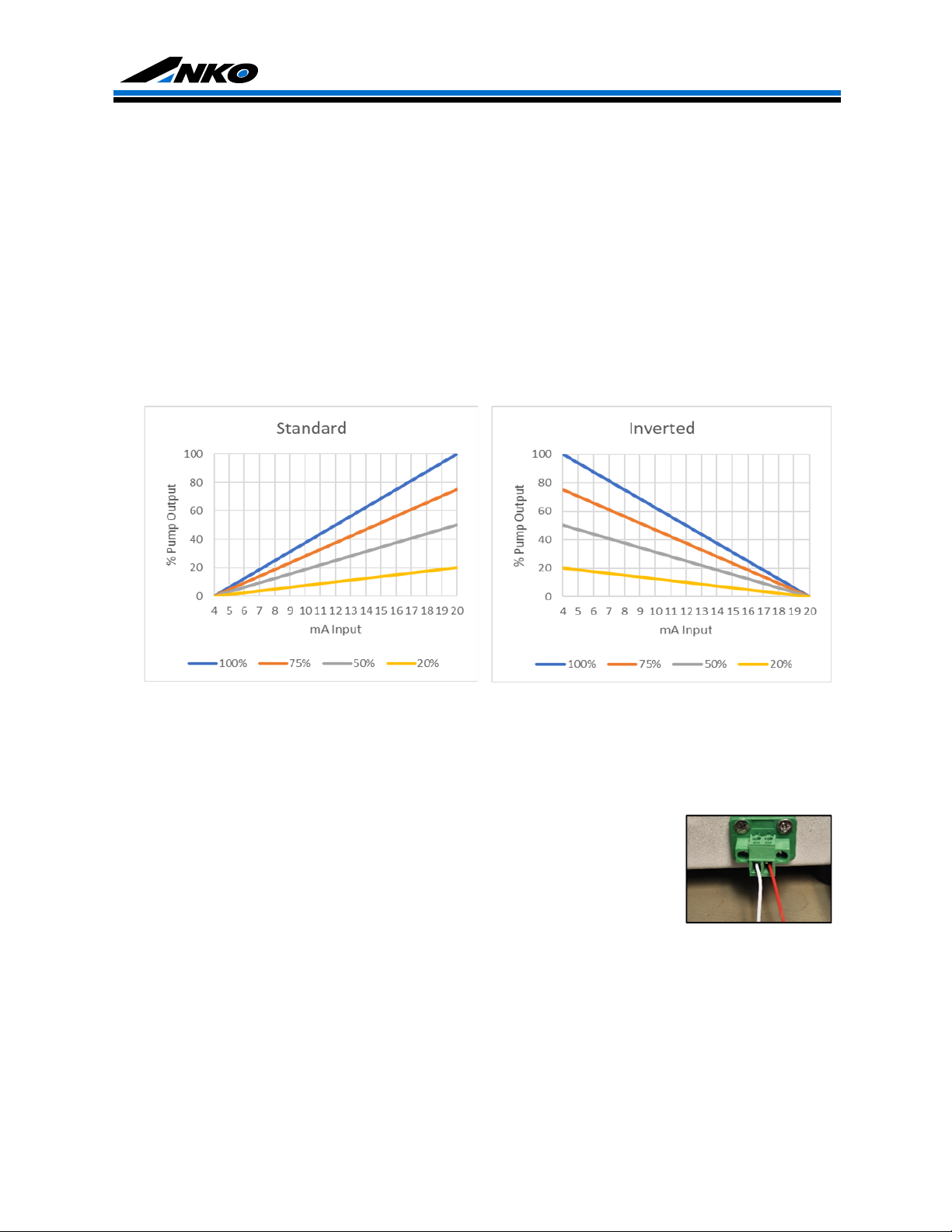

Flow output is controlled by motor speed utilizing the potentiometer. Rates are adjustable from

approximately 5% to 100%. If equipped with a 4-20mA control option, pump speed will vary as the

dedicated input signal changes amplitude. Please refer to Remote Operation below for more details

on 4-20mA operation.

4.3 Remote Operation

Remote Start/Stop – For pump models equipped with remote start/stop, this feature operates by

receiving a dry contact signal and is intended to be connected to a dry contact switch. The input has

no polarity. No voltage is permitted on the input signal. The pump will activate and run while the

switch is closed and deactivate and stop when the switch opens.

To establish and operate this feature:

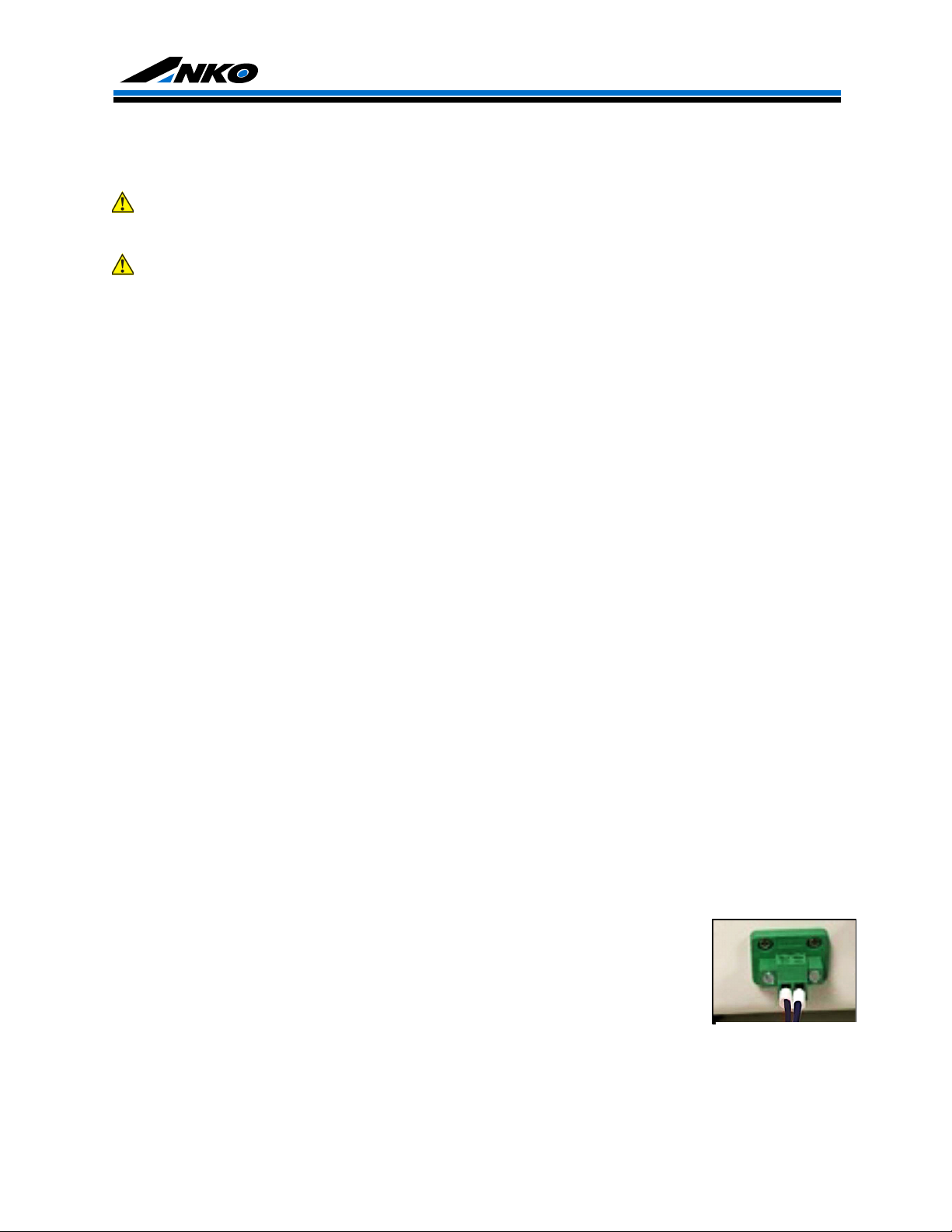

1. To activate this feature, install the pair of wires from the dry contact switch

closure device into the terminal block (Figure 1)

2. Set the MODE switch to IN for External mode. The pump will now operate

only when receiving a dry contact signal.

To return the pump local control, set the MODE switch to OUT for Internal mode.