Rev F 5/9/17 pg. 5

Introduction

ANKOM Technology designs, manufactures, and markets instruments and support products used by analytical

laboratories around the world in the environmental, agricultural, biomass, and food industries. ANKOM

Technology can provide you with products for determining or monitoring dietary fiber, detergent fiber, fat,

digestibility, microbial fermentation (anaerobic or aerobic) and more.

Committed to Total Customer Satisfaction, ANKOM designs every product based on a thorough assessment of

customer needs.

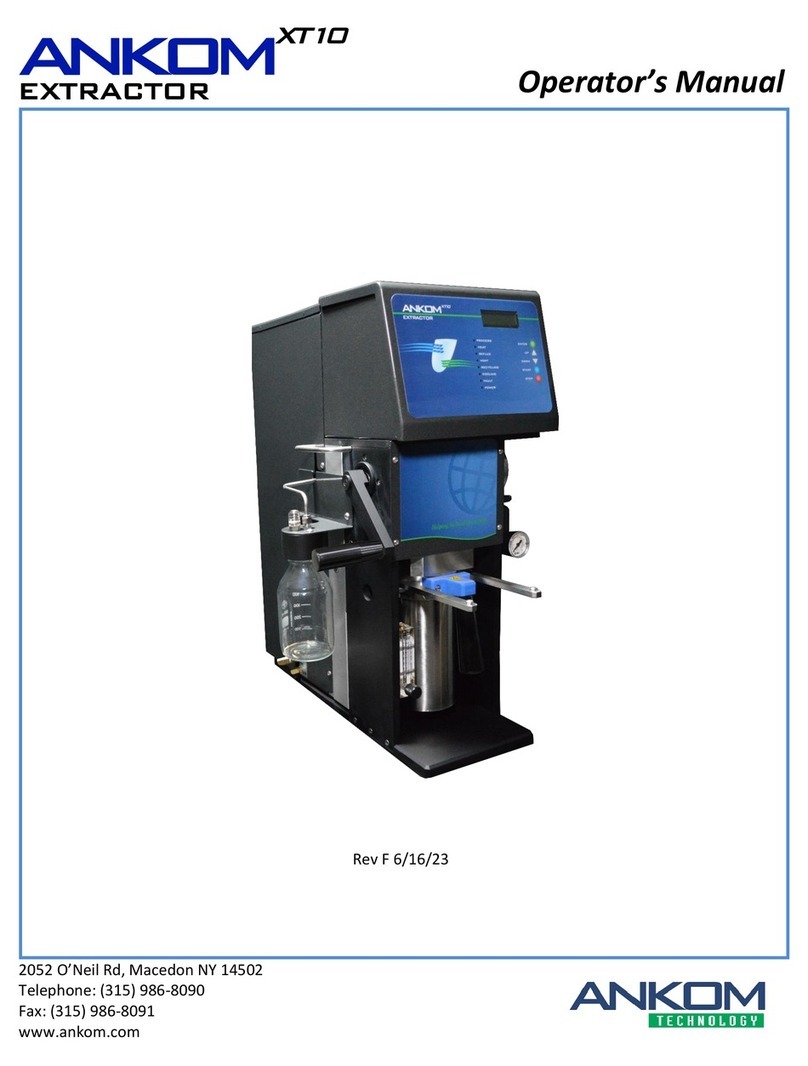

Congratulations on your purchase of the ANKOMXT15 Extraction System.We are confident that this product will

effectively serve your needs.

The ANKOMXT15 Extraction System was designed to automate the process of fat extraction. This reduces

technician variation, increasing precision. By carefully following the operating instructions in this manual you will

understand the details of sample and filter bag handling as well as the instrument controls, helping you to achieve

the best possible results.

Please review the entire contents of this manual before you begin operating this

product.

Warranty

ANKOM Technology warrants the ANKOMXT15 Extraction System against any defects due to faulty workmanship

or material for one year after the original date of purchase. This warranty does not include damage to the instrument

resulting from neglect or misuse. During the warranty period, should any failure result from defects in

workmanship or materials ANKOM Technology will, at its discretion, repair or replace the instrument free of

charge.

Extended warranties are available upon request.

Filter Bags

Use only ANKOM Technology filter bags (part # XT4) in your ANKOMXT15 Extraction System. Use of any other

filter mechanism will void the warranty. Filter bags can be purchased from ANKOM Technology or from your local

authorized ANKOM distributor.

Operating Environment

Your ANKOMXT15 Extraction System is designed to operate within the following environments:

Ambient Temperature Range: 15°−35°C

Power: 100V−120V ~ 50/60Hz 10A

220V−240V ~ 50/60Hz 5A