Table of Contents

Introduction..................................................................................................................................................................5

Warranty.......................................................................................................................................................................5

Filter Bags .....................................................................................................................................................................5

Operating Environment ................................................................................................................................................5

Contact Information .....................................................................................................................................................6

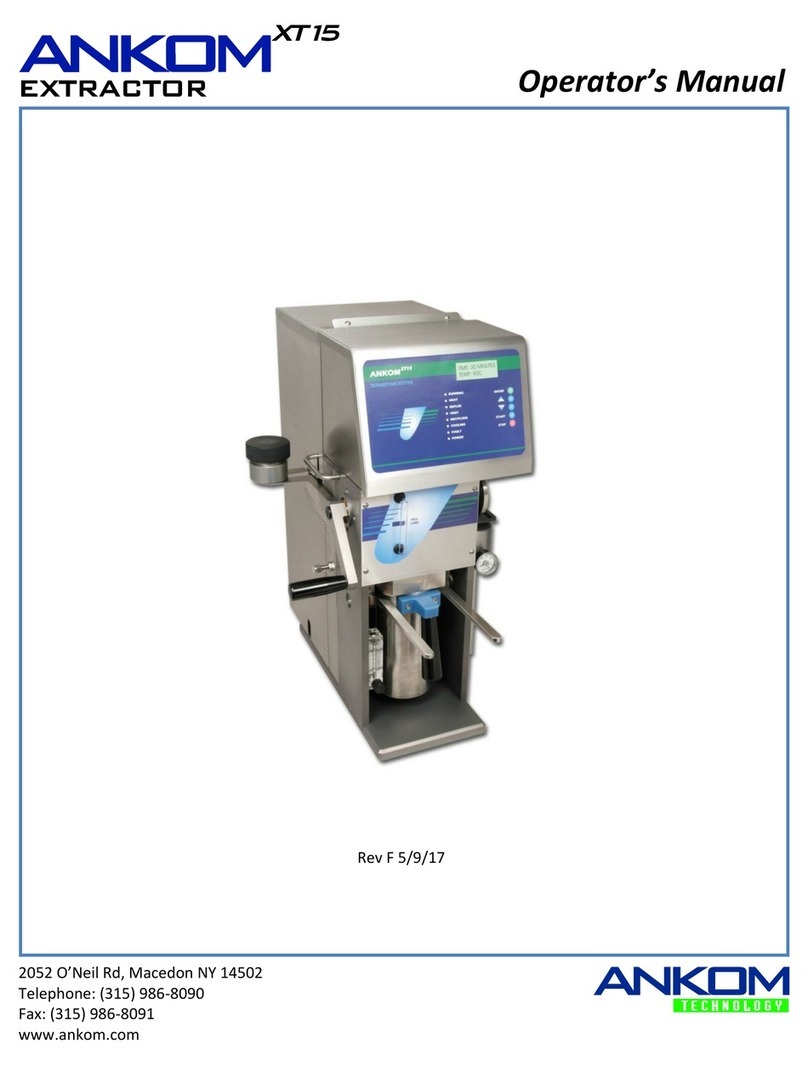

Instrument Description.................................................................................................................................................7

Safety Precautions ........................................................................................................................................................8

Instrument Installation and First Run...........................................................................................................................9

Fat Extraction Calculations .........................................................................................................................................13

Fat Extraction Support Items......................................................................................................................................14

Sample Preparation ....................................................................................................................................................15

Fat Extraction step-by-step procedure using the ANKOMXT10 ....................................................................................21

Periodic Maintenance.................................................................................................................................................25

Troubleshooting & Replacement Parts.......................................................................................................................27

Diagnostics..................................................................................................................................................................29

Appendix A - Analytical Procedure .............................................................................................................................33

Appendix B –Electrical Diagram ................................................................................................................................35