-4- -5-

WTarget output and concentration

The WATA-Plus®uses electrolysis of salt water at 25 g/L (375 grams of salt per 15 litres

of water) to produce a sodium hypochlorite solution with a 6 g/L concentration of active

chlorine. Failure to follow these parameters could lead to a poor quality production or

a damaged power supply.

WIn case of unstable current, use a voltage regulator

If the power grid is subject to intermittent outages or sudden voltage dips and surges

(fluctuations in the intensity of light emitted by the bulbs provide sufficient evidence

that this is occurring), the power supply could be destroyed. If this is the case, use a

voltage regulator. Likewise, if a generator has a large variation in operating regimes, it

is advisable to use a voltage regulator.

WUse with a generator

The generator should not run out of fuel while the WATA-Plus®is in use. Ensure that the

tank is full before starting production. Wait until the generator is stable before plugging

in the WATA-Plus

®

.When the procedure is complete, first unplug the WATA-Plus

®

’s power

supply and then turn off the generator.

WRespect the prescribed production volumes.

The recommended volume of each production run is 15L.

WOverheating of the power supply

If overheating occurs, the power supply will automatically shut off and then restart when

its internal temperature falls below 70°C. However, it is advisable to stop the procedure

and allow the power supply to cool down for 15 minutes.

WRespect the 6 g/L concentration

The WATA-Plus®is designed to produce a sodium hypochlorite solution with a 1 to 6

g/L concentration of active chlorine.The concentration must not exceed 7 g/L. Prolonged

use or excessive salt will result in raising the temperature of the bath, not in increasing

concentration. If this occurs, there is a risk of damaging the power supply and/or not

achieving 6 g/L concentration. Use WataTest®to measure concentration once the

procedure is complete.

WWater temperature for production

To begin the procedure, use water with a temperature between 20 and 27°C. Check the

temperature using a clean thermometer.

WUse a log book

To facilitate the monitoring of chlorine production and to trace the origin of any problems

that might arise, use a log book to record, each time the WATA-Plus®is used, the name

of the person responsible for production, the starting and finishing times of production

and a short description of the procedure. You’ll find examples in the «tool kit» on our

website, www.antenna.ch.

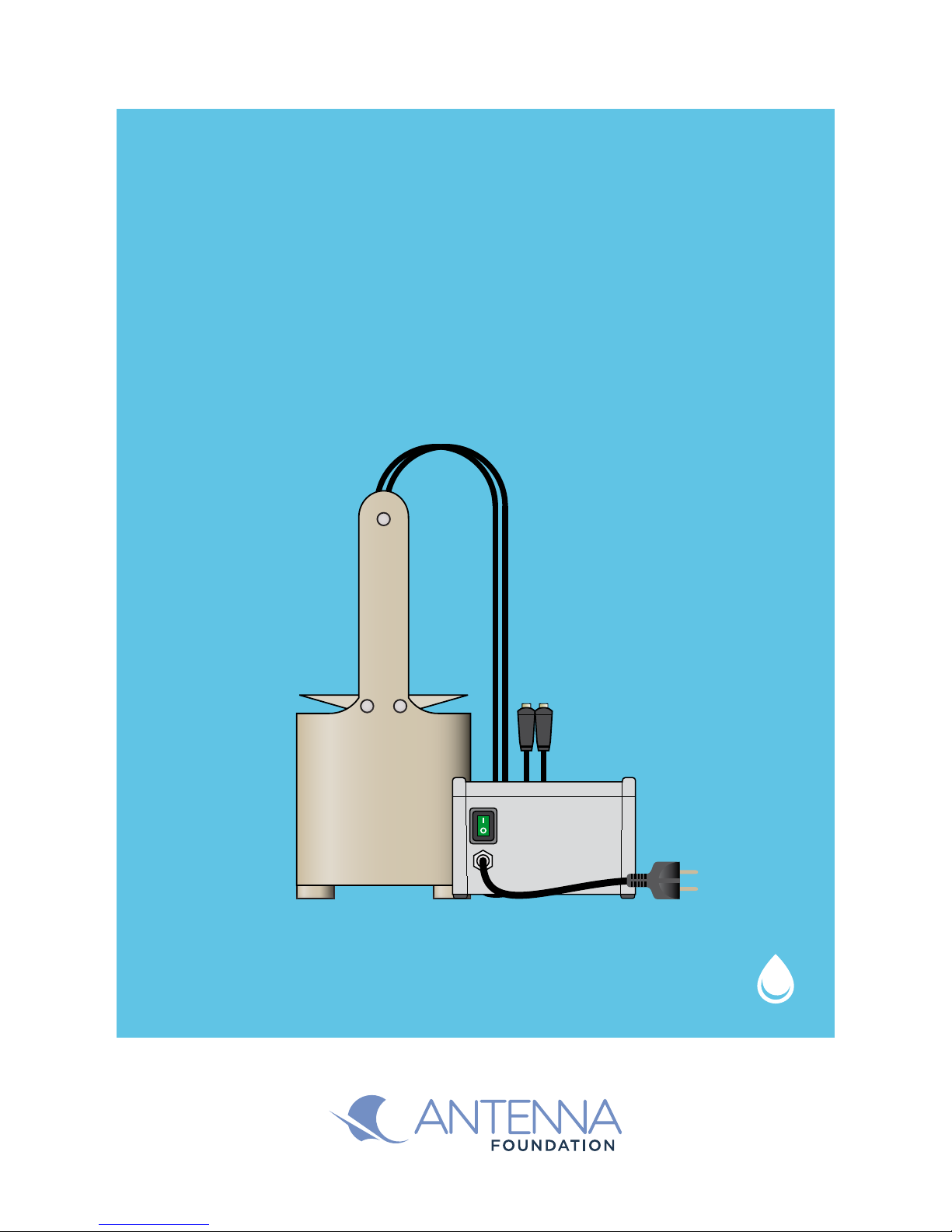

2. NECESSARY MATERIALS

`WATA-Plus®kit

`Ordinary salt

`Clear water

`Funnel

`Plastic container holding approximately 25L

`Wooden/plastic table

3. RECOMMENDATIONS FOR THE

PRODUCTION OF SODIUM HYPOCHLORITE

WChoose one or several people to be responsible for production

These persons should be trained and possess a general knowledge of chemistry.

Production with the WATA-Plus®involves more than just adding salt to water. Failure to

follow indicated procedures will lead to excessive energy consumption that will adversely

affect the proper functioning and life span of the power supply.

WSome precautions at the electrical level

The box containing the power supply should be put in a dry area away from splashing

water and should always remain closed, especially when the WATA-Plus®is in use. It

should be placed as far as possible from the chlorine vapours and never placed

at ground level. It should be opened only by qualified persons with electrical training

after the power supply has been unplugged. The electrical voltage in the electrolysis

bath involves no risk of electrocution for the user. However, precautions should be

taken regarding access to the device only by authorized persons. Furthermore, salt and

chlorine are not good for electrical devices, so rinse your hands/gloves before handling

the power supply.

WChoose an appropriate area and time for production

Only those persons specially trained in using the WATA-Plus®should use it. Owing to

significant emissions of hydrogen (a highly flammable gas) produced during electrolysis,

when the WATA-Plus®is in use, the device should be kept far from fire, flame and

sparks. In addition, it is advisable not to inhale the chlorine emissions, which are also

produced during electrolysis, and to work in a well-ventilated room. Production should

be carried out in a ventilated area with a temperature between 25 and 30°C,

protected from dust and the sun’s rays. In countries with a hot climate, it is best to work

early in the morning or in the evening, when temperatures are lower.