P/N 1011598 Rev. A 11/20

8

RESIDENTIAL WATER SOFTENER

Drain Connection

The drain is for regenerating the softener

resin and for ushing particle buildup out

of the system during operation.

1. Apply pipe thread tape to threads

of the drain tting and attach the

drain tting to the control head at

the drain port. Do NOT overtighten

the tting into the control head.

2. Attach the 1/2” ID drain hose to

the barb of the drain tting, and

secure with a hose clamp.

3. Measure a sucient length of

hose from the drain outlet tting to

the drain.

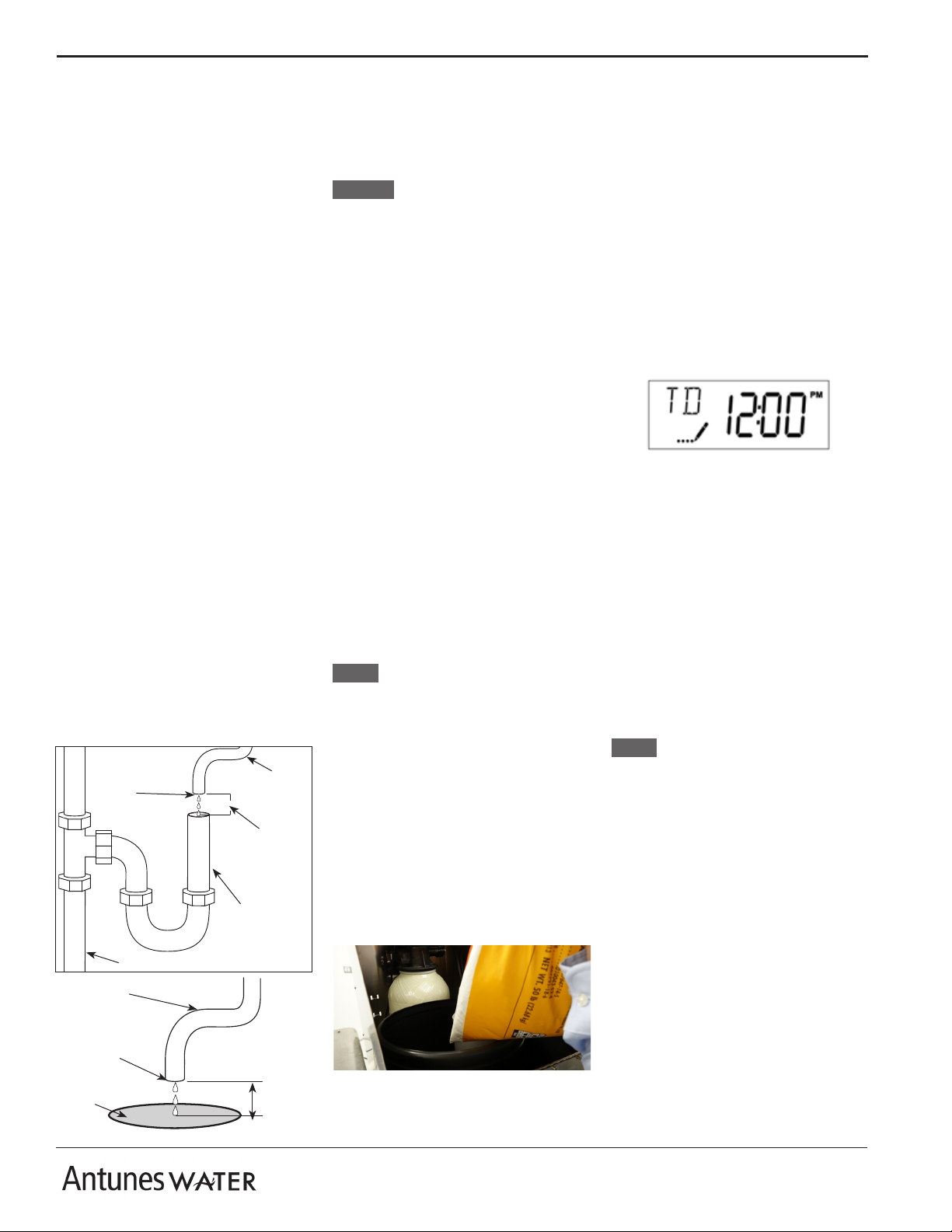

When connecting the drain hose, pay

attention to the following guidelines:

yThe drain line plumbing must

be able support the ow rate

when the system regenerates.

yThe drain line leading out of

the system must be as short as

possible and slope downwards

without any kinks or loops.

yThe drain line plumbing must

be positioned and secured at

least 2 inches above the drain

(Figure 3). This air gap protects

the system from contamination in

the event of a backed-up drain.

yThe drain used must not be

blocked or restricted.

yThe drain used must be as large or

larger than the drain line plumbing.

yThe drain line from the

system should be secured at

the drain using appropriate

mounting hardware.

4. Attach 3/8” OD brine tank tubing

to the control head using the brass

nut and sleeve provided. Do NOT

overtighten the brass nut.

5. Attach the other end of the brine

tank tubing to the brine tank oat

valve using the supplied nut and

sleeves.

OPTION: If desired, connect the brine

tank overow hose from the

overow tting to the oor

drain.

6. Attach Hi-Flo bypass valve to the

control head.

7. Attach the plastic yoke to the

bypass valve.

8. Turn o main water supply.

9. Remove a section of existing pipe

where the softener is going to

be installed. The pipe removed

should be large enough to allow

the ttings needed to connect to

the softener system.

10. Make sure to verify the inlet and

outlet water ow directions on the

softener and the existing plumbing

before making connections.

11. Connect the incoming untreated

water to the valve inlet. Connect

the outlet water connection to the

rest of the home plumbing.

12. Attach inlet and outlet ttings to

the plastic yoke. The yoke has 1”

NPT male threads. Use pipe tape

and/or pipe dope on the threads.

Use a backup wrench when mak-

ing pipe connections. Do NOT

overtighten ttings onto the plastic

yoke.

NOTE: Make sure that local plumbing

codes are followed when mak-

ing connections.

13. Before proceeding, make sure the

bypass valve is in bypass position.

Bypass position is when the valve

handles are across (perpendicular

to) the valve bodies.

14. Turn on the main water supply and

check all new ttings for leaks.

15. Secure the power transformer on

the power cord to the wall or other

location to remove the weight of

the transformer from the cord.

16. Remove the lid of the brine tank

and ll the brine tank with softener

salt (at least 50 lbs.) Replace the

lid when nished.

17. Plug the power cord from the

control head into a grounded GFCI

outlet. Make sure the control panel

is illuminated.

2” (5.1 cm)

minimum

Floor Drain

Secure End

Drain Line

from System

2” (5.1 cm)

minimum

Drain Line

from System

Secure

End

Drain

Standpipe

Figure 2. Drain Line Plumbing

Setting the Clock

Program the controller to set the time of

day.

1. Press and hold either the Up or

Down arrow button on the control-

ler until the programming icon

replaces the service icon and the

parameter display reads TD (Time

of Day).

2. Adjust the displayed time with the

Up and Down buttons.

3. When the correct time is set, press

the Extra Cycle button to lock in

the time and resume normal op-

eration. The unit will also return to

normal operation after 5 seconds if

no buttons are pressed.

Placing the System into

Service

1. After the time of day is set, open

the bypass valve. The open posi-

tion is when the valve handles are

in line with (parallel to) the valve

bodies.

2. Check for leaks at all connections

on the softener control head.

3. Activate a manual regeneration

by pressing and holding the extra

cycle button for 5 seconds. Air and

water will come out of the softener

drain line and water will ll the salt

brine tank.

NOTE: The regeneration will take

approximately an hour to

complete.

4. After the regeneration is complete,

the system is operational.

Operation Check

1. Make sure the water supply to the

softener is on.

2. Proper hardness reduction can be

checked by measuring a sample

of the outlet water for hardness.

3. Collect a water sample from any

tap leading from the softener

system. Run the water for several

minutes to make sure soft water is

at the tap.

4. Measure the hardness using any

test that measures total hardness.