DiaLog Elite PLC Interface Manual

©

Antx, inc. 2001 Version 1.2 v

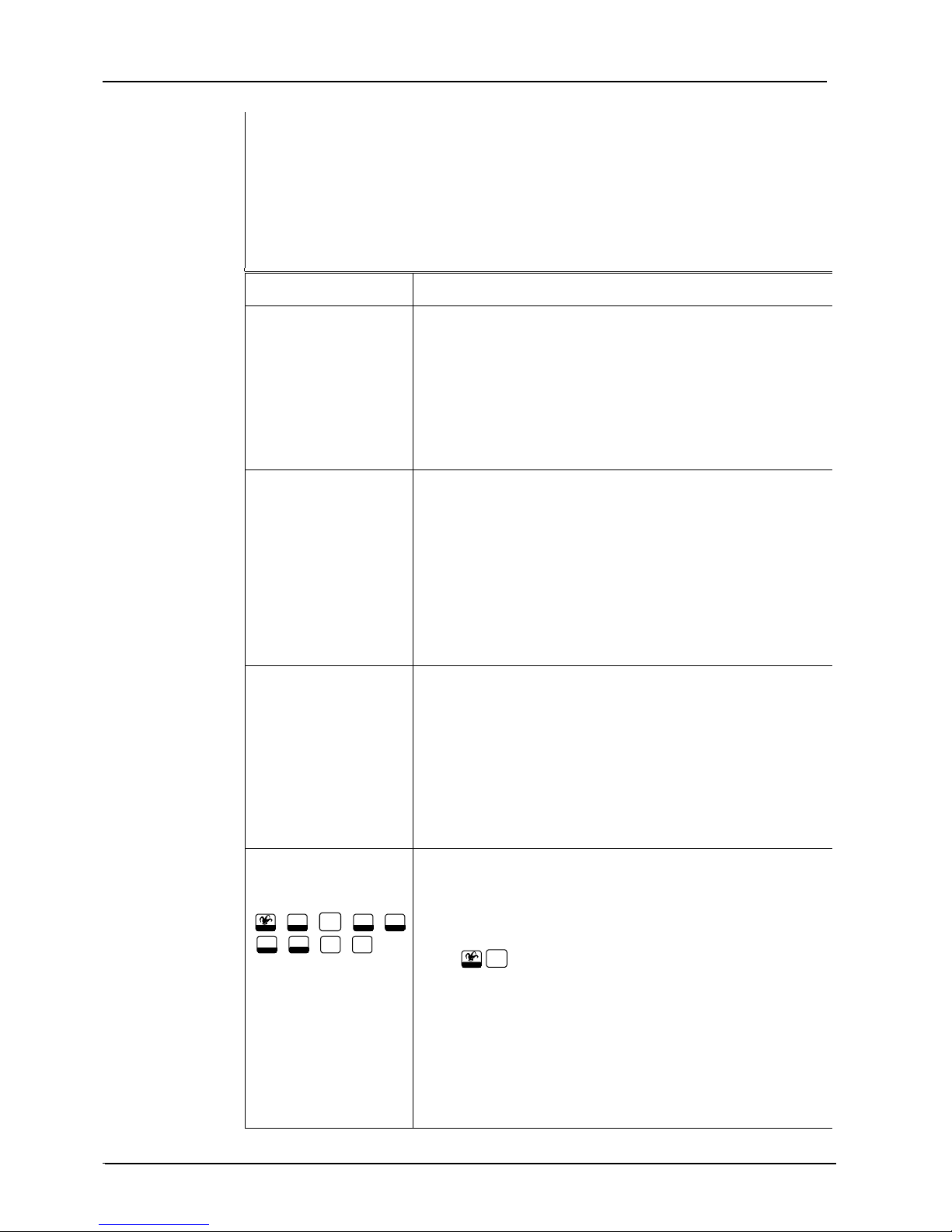

Convention Description

Small rectangular

representation of key

0.1 2 3.4.5.

.6 7.8.9.0.*.

.#.F1.F2.F3.F4.

Indicates keys to press when entering parameter values at the

keypad or when communicating with the DiaLog via a touch-

tone telephone.

EXAMPLE 1:

The person answering the call acknowledges it by pressing the

.* , 8 or 9 key on a Touch-Tone telephone.

EXAMPLE 2:

In Chapter 7, Programming the DiaLog Elite, 0 - 2 in the

What you Enter column means to enter a value between 0 and

2.

Small rounded

rectangular

representation of a key

These keys are used in Chapter 7, Programming the DiaLog

Elite, to indicate menu selections. These are used in both the

Road Map and the Menu Sequence headings.

0123 EXAMPLE:

4567 9Æ0Æ3

8 9 Means to press the keys 9, 0 and 3 to reach the command.

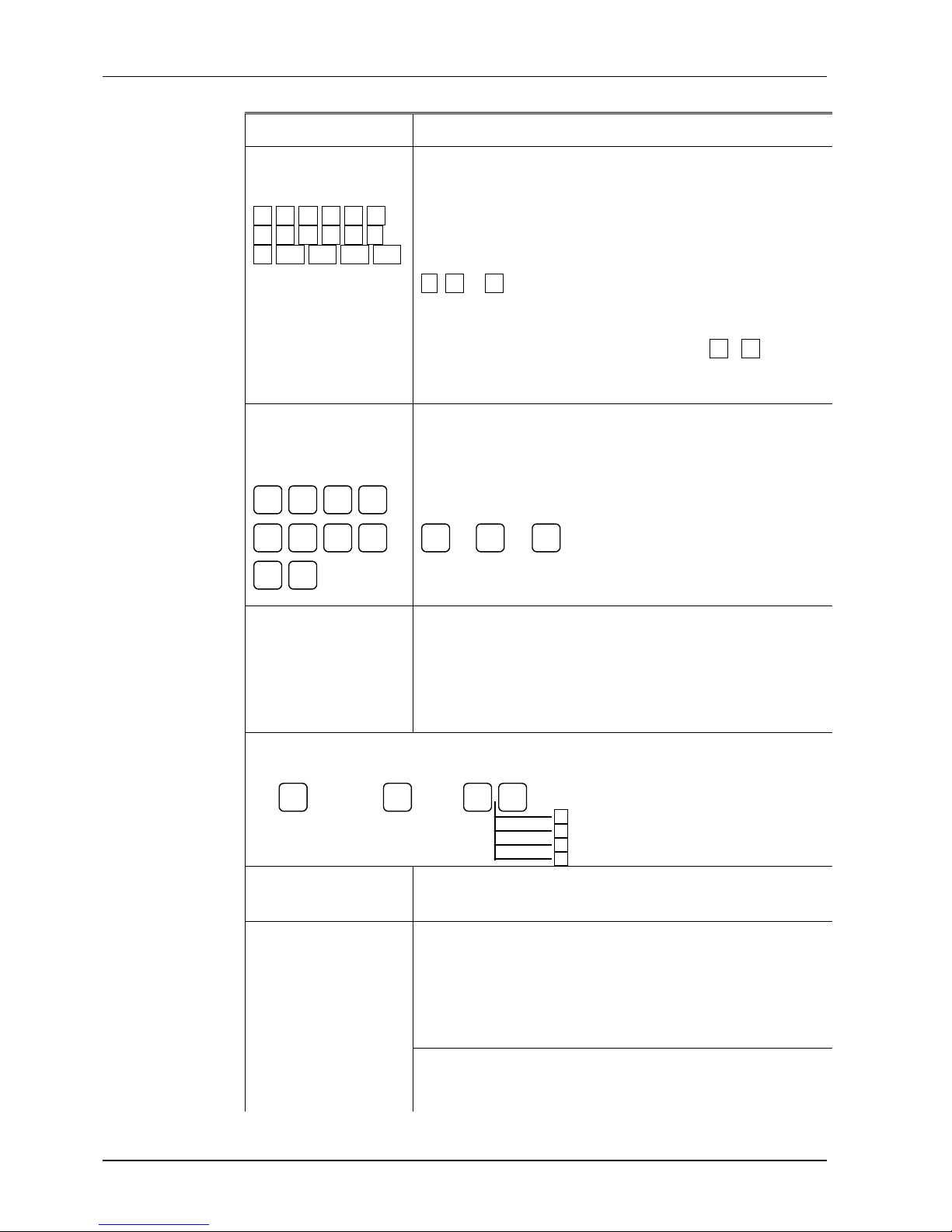

Road Map ÞThis heading and icon is used at the beginning of a function

description to indicate the complete key sequence that the user

takes to reach the function being described. The Road Map also

includes other parameters within that function.

EXAMPLE:

Channel

Configuration

Relay

Output

Channels

Channel

Number

9Æ3

Æn n

0 Pulse Duration [0-65535]

1 De-energize Relay on Ack.[0-1]

2 Channel Mode [0-1]

3 Channel Alpha ID [A-Z, 0-9]

Description This heading and icon is used to present an overview of the

function being discussed.

Field Summary This heading and icon is used to list all parameters that must be

entered for the function. The heading includes the name of the

Field, Range of values that can be entered, and Factory

Setting.

EXAMPLE:

Field Range Factory Setting

Alarm Delay 0-65535 seconds 3