3

Table of Contents

1Description.............................................................................................................................6

1.1 Capabilities.....................................................................................................6

1.2 Monitoring .....................................................................................................6

1.3 Host Server Communications.........................................................................6

2Installation and Setup.............................................................................................................9

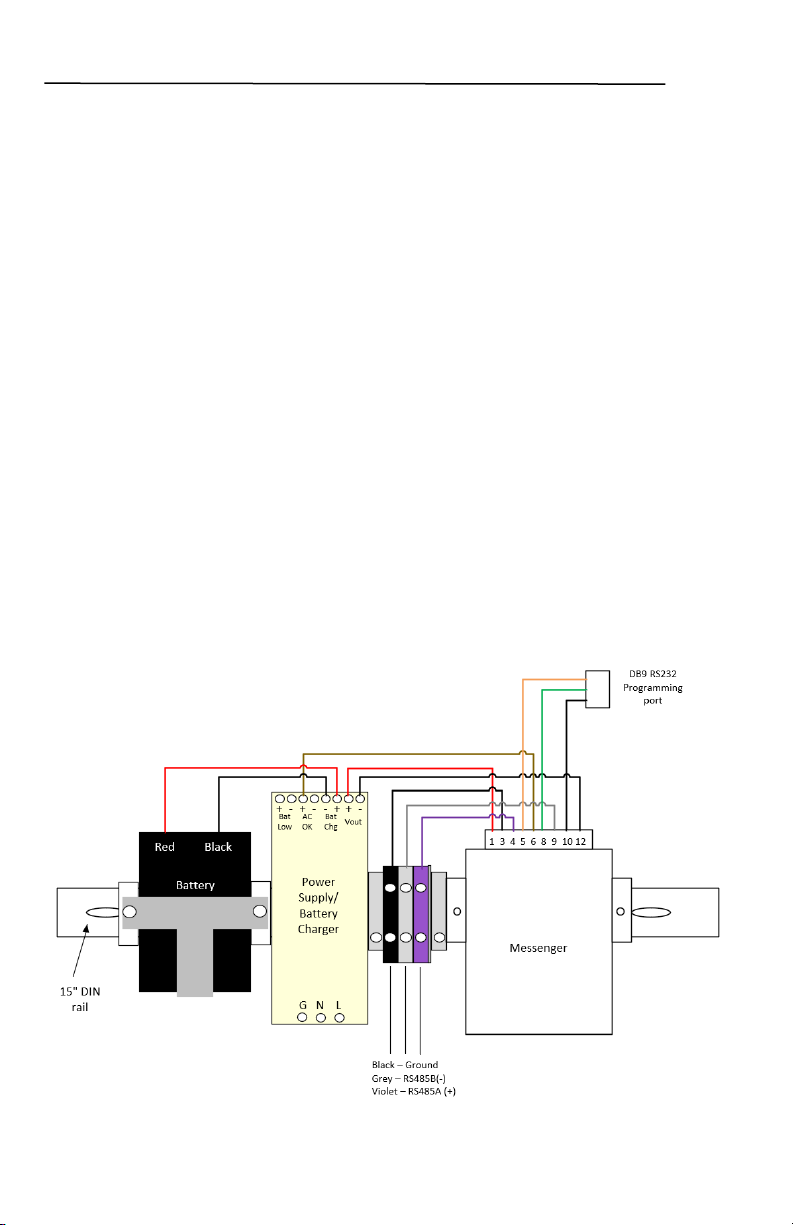

2.1 Installation Steps ............................................................................................9

2.2 Mounting the Equipment................................................................................9

2.3 Mounting the Antenna..................................................................................10

3LED States ...........................................................................................................................11

4Channels...............................................................................................................................14

4.1 Defined Channels......................................................................................... 14

4.2 Channel Data................................................................................................ 15

5Modbus ................................................................................................................................15

5.1 RTU Slave....................................................................................................15

5.2 RTU Master.................................................................................................. 15

6Debug Menu.........................................................................................................................16

6.1 Default Configuration and Sample Session.................................................. 17

7Configuration .......................................................................................................................18

7.1 Debug Configuration Commands.................................................................19

7.2 Site Configuration – Type 1.........................................................................22

7.3 Options Configuration – Type 2...................................................................23

7.4 CELL Configuration – Type 3 ..................................................................... 24

7.5 FTP Configuration – Type 4 ........................................................................26

7.6 Serial Port Configuration – Type 6 .............................................................. 27

7.7 Channel Configuration – Type 9..................................................................29

7.8 Report Flag Configuration – Type 12 ..........................................................34

7.9 Date/Time Configuration – Type 16 ............................................................36