REV 11 -1401031355 L-C2-179

2

AVERTISSEMENTS ET CODES DE SÛRETÉ

INSTALLATEUR: Laissez ces instructions avec le

consommateur.

CONSOMMATEUR: Maintenez pour la future référence.

INSTALLATION ET CONSIGNES

D’UTILISATION

DANGER

S’il y a une odeur de gaz:

1. Coupez l’admission de gaz de l’appareil.

2. Éteindre toute flamme nue.

3. Ouvrir le couvercle.

4. Si l’odeur persiste, gardez loin de l’appareil,

et appelez immédiatement le fournisseur de

gazou le service d’incendie.

AVERTISSEMENT

1. Ne pas entreposer ni utiliser de l’essence ni

d’autres vapeurs ou liquides inflammables

dans le voisinage de l’appareil, ni de

proximité de tout autre appareil.

2. Une bouteille de propane qui nest pas

raccordée en vue de son utilisation, ne doit

pas être entreposée dans le voisinage de

cet appareil ou de tout autre appareil.

CONDITIONS DE CODE ET

D’APPROVISIONNEMENT: Ce barbecue doit

être installé selon des codes et des ordonnances

locaux, ou, en l’absence des codes locaux, avec

l’un ou l’autre le plus défunt code national de gaz

de carburant (norme ANSI Z223.1/NFPA 54), et le

code d’installation de gaz naturel et de propane

(CSA-B149.1).

Cet appareil et ses différents robinets d’isolement

doivent être démontés du système sifflant d’offre

de gaz en examinant le système aux pressions au-

dessus du ½ psig (kPa 3.5).

Cet appareil doit être isolé dans le système sifflant d’offre

de gaz par fermeture ses différents robinets d’isolement

manuels pendant tous les essais sous pression du circuit

d’alimentation de gaz aux pressions jusques et y compris

Toutes les sorties électriques à proximité du barbecue

doivent être correctement fondues selon des codes

locaux ou, en l’absence des codes locaux, avec le code

électrique national, ANSI/NFPA 70, ou le code électrique

canadien, CSA C22.1, qui est jamais applicable.

Gardez tout cordon d’alimentation électrique et tuyau

d’alimentation en combustible a l’écart des surfaces

chauffées.

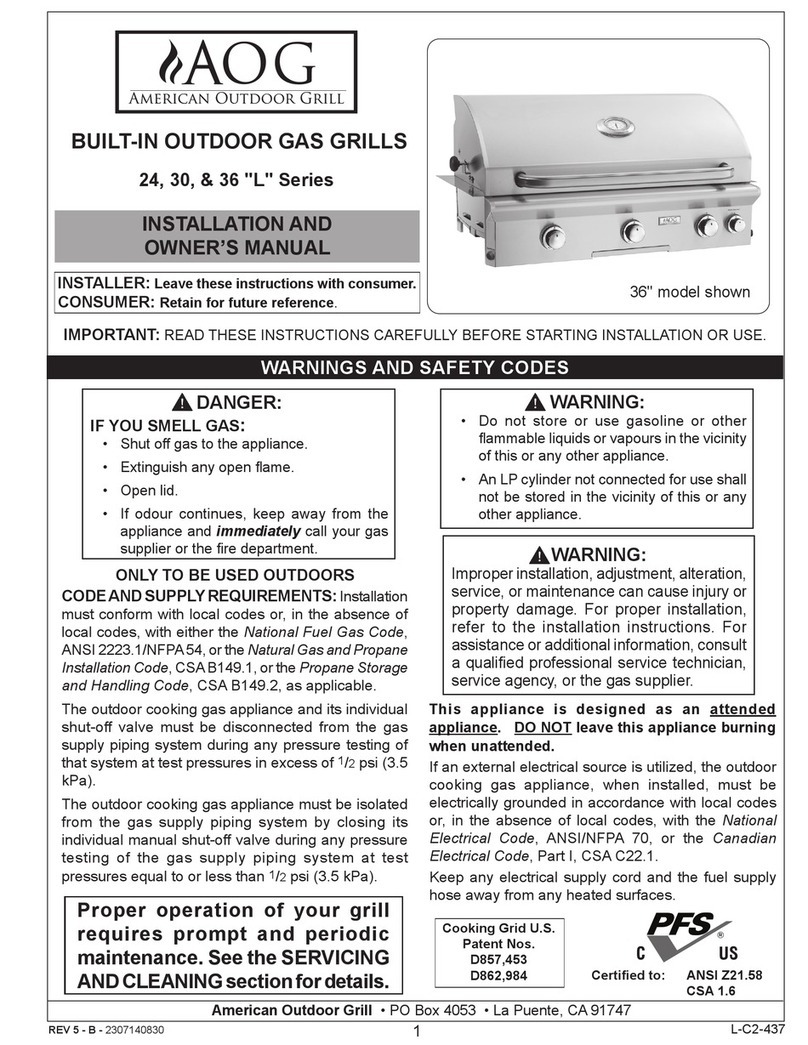

24, 30 et 36 SÉRIES

LE GAZ EXTÉRIEUR GRILLE TOUT

LE GAZ EXTÉRIEUR GRILLE TOUT

ENTIER LE MODÈLE DE SLIDE-IN

ENTIER LE MODÈLE DE SLIDE-IN

AVERTISSEMENT

L’installation inexacte, l’ajustement, le

changement, le service ou l’entretien

peuvent causer des dommages ou

des dégats matériels. Référez-vous à

ce manuel. Pour l’aide ou l’information

additionnelle consultez un installateur

qualifié et professionnel, l’agence de

service, ou le fournisseur de gaz.

Important: Lisez ces instructions

soigneusement avant de

commencer l’installation.

American Outdoor Grill • PO Box 4053 • La Puente, CA 91747

09-06

Certifié à la norme ANSI : Z21.58b-2012

CSA : 1.6b-2012