5

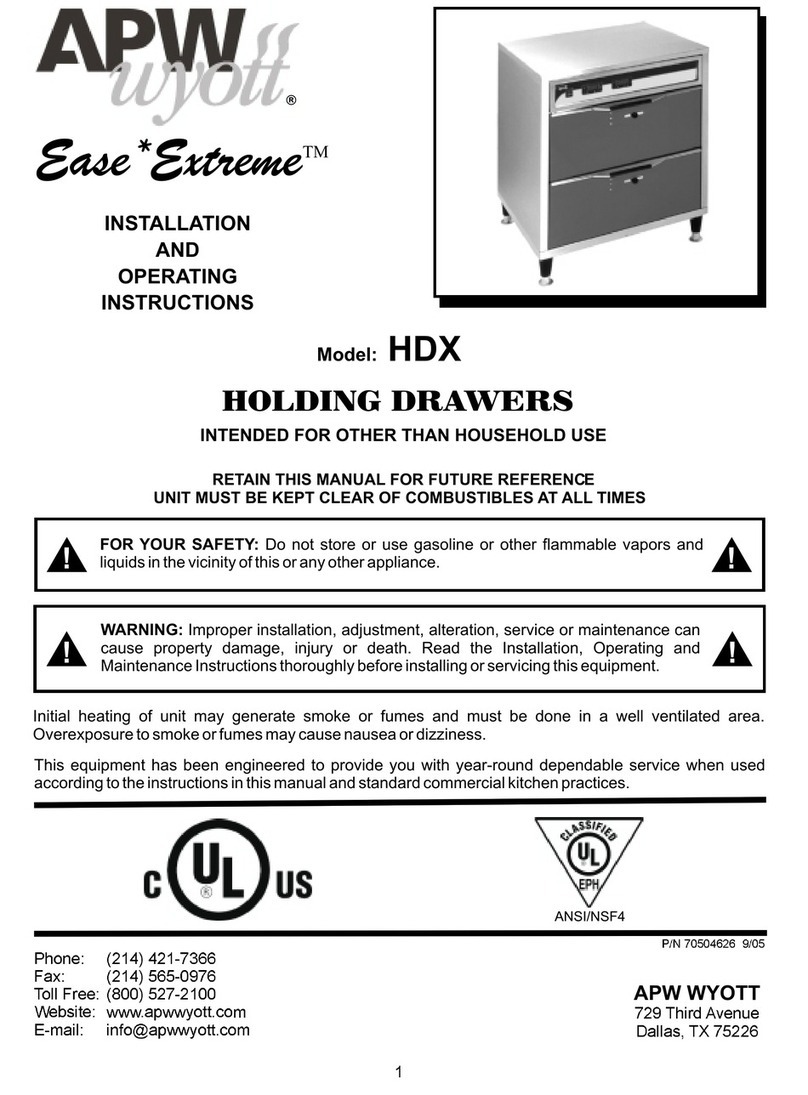

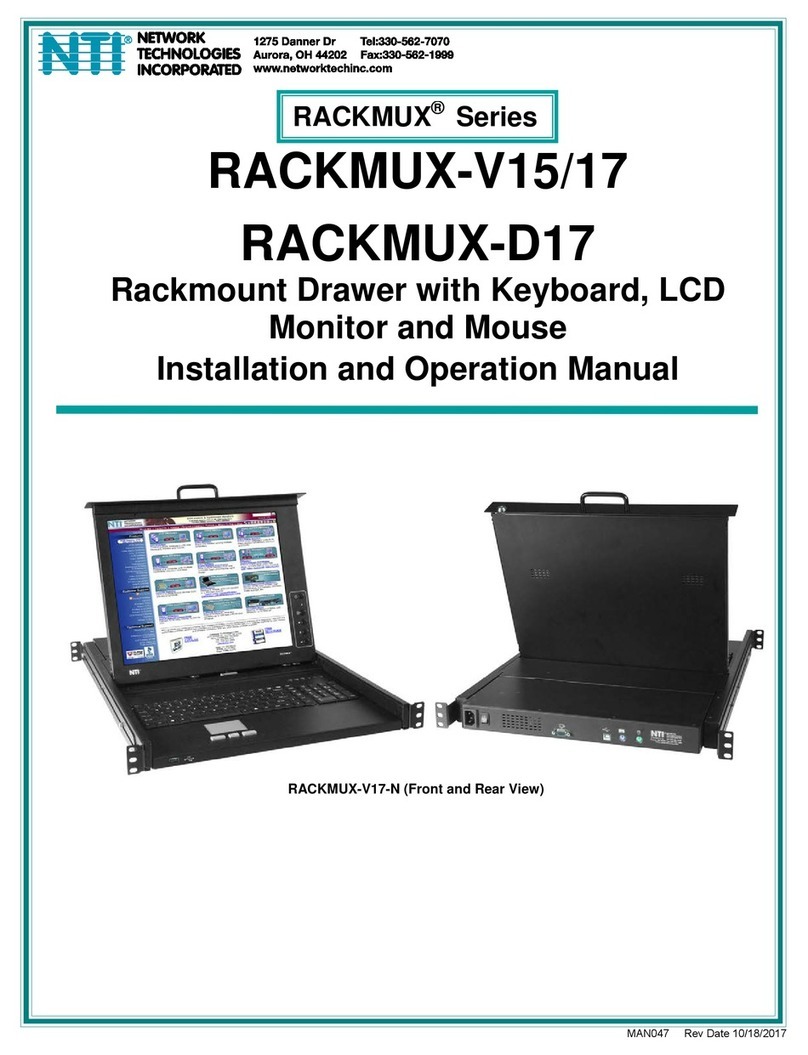

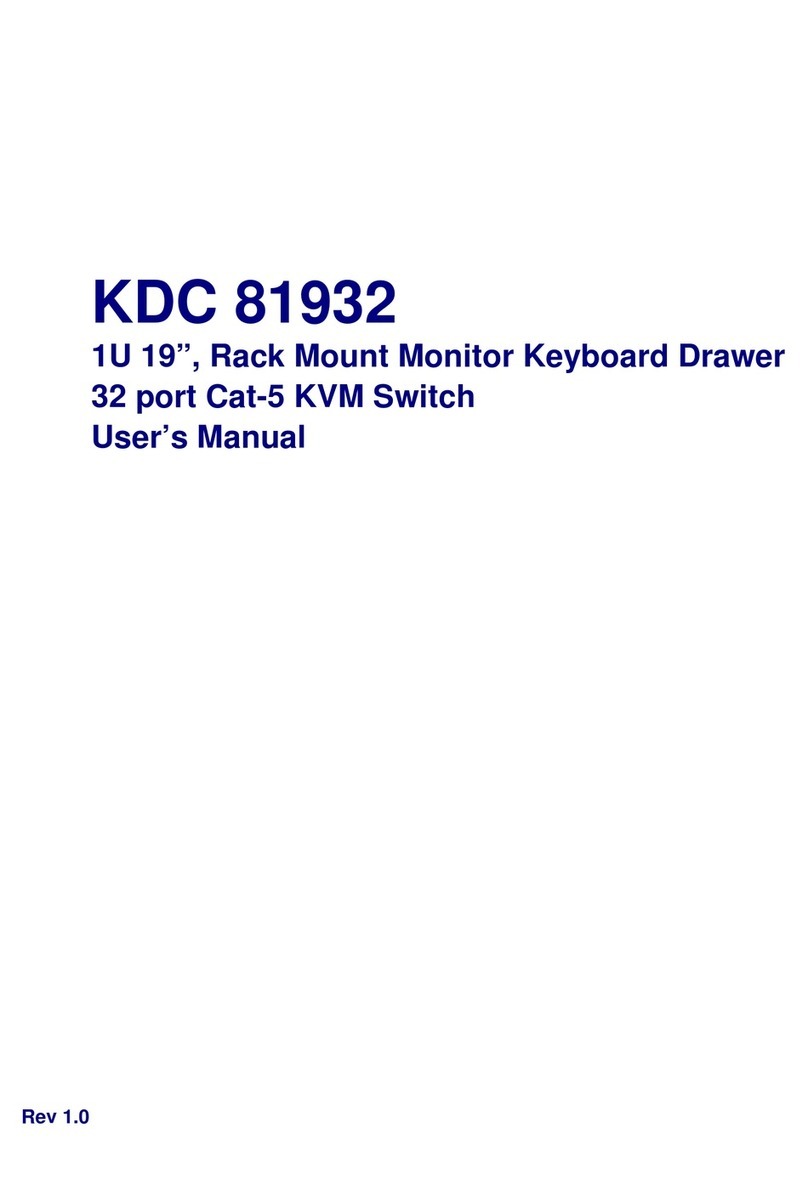

Fig. 5-1 Type I Acme thread quick coupler

Pressure

relief

valve

QCC

Type 1

valve

Brass Acme

thread fitting

Liquid level

indicator

(optional)

Hand nut with Acme

thread

Regulator

Vent

Hose

Hand wheel

The use of pliers or a wrench should not be necessary. Only

cylinders marked “propane” may be used.

To disconnect: Turn the hand nut counterclockwise until

detached (Fig. 5-1).

Important: Before using the unit, and after each time

the cylinder is removed and reattached,

check the hose for wear (see a.) and check

all connections for leaks. Turn off the unit

valves and open the main cylinder valve,

then check connections with soapy water.

Repair any leaks before lighting the unit.

CAUTION: Always turn the propane cylinder main valve

off after each use, and before moving the unit

and cylinder or disconnecting the coupling.

This valve must remain closed and the

cylinder disconnected while the appliance

is not in use, even though the gas flow is

stopped by a safety feature when the coupler

is disconnected.

Carefully inspect the hose assembly each time before the

gas is turned on. A cracked or frayed hose must be replaced

immediately.

If the appliance is stored indoors, the cylinder must be

disconnected and removed. Disconnected cylinders must be

stored outdoors, out of the reach of children, with threaded

valve plugs tightly installed, and must not be stored in a

building, garage, or any other enclosed area.

FOR YOUR SAFETY

a. DO NOT store a spare propane-gas cylinder under or

near this appliance.

b. NEVER fill the cylinder beyond 80-percent full.

c. IF THE INFORMATION IN a. AND b. IS NOT FOLLOWED

EXACTLY, A FIRE CAUSING DEATH OR SERIOUS

INJURY MAY OCCUR.

IMPORTANT FOR YOUR SAFETY

READ AND FOLLOW ALL WARNINGS PROVIDED WITH THE PROPANE-GAS CYLINDER.

When operating this appliance with a propane-gas cylinder, these instructions and warnings MUST be observed.

FAILURE TO DO SO MAY RESULT IN A SERIOUS FIRE OR EXPLOSION.

CYLINDER/CONNECTOR REQUIREMENTS

a. Propane-gas cylinders, valves, and hoses must be

maintained in good condition and must be replaced if

there is visible damage to either the cylinder or valve. If the

hose is cut or shows excessive abrasion or wear, it must

be replaced before using the gas appliance (see e.).

b. This unit, when used with a cylinder, should be connected

to a standard 5-gallon (20 lb.) propane-gas cylinder

equipped with an OPD (Overfill Prevention Device).

The OPD has been required on all cylinders sold since

October 1,1998, to prevent overfilling.

c. Cylinder dimensions should be approximately 12" (30.5

cm) in diameter and 18" (45.7 cm) high. Cylinders must

be constructed and marked in accordance with the

Specifications for Propane Gas Cylinders of the U.S.

Department of Transportation (D.O.T.) or the National

Standard of Canada, CAN/CSA-B339, Cylinders,

Spheres, and Tubes for Transportation of Dangerous

Goods.

d. The cylinder used must include a collar to protect the

cylinder valve, and the cylinder supply system must be

arranged for vapor withdrawal.

e. The pressure regulator and hose assembly (Fig. 5-1)

supplied with this outdoor gas appliance (L.P. models

only) must be used. Original and replacement pressure

regulator and hose assemblies must be those specified by

the manufacturer for connection with a cylinder connecting

device identified as Type I by the ANSI Z 21.58/CGA 1.6

(see PARTS LIST for ordering information).

f. The propane-gas cylinder valve must be equipped with a

cylinder connection coupling device, described as Type I

in the standard defined in paragraph e. above.This device

is commonly described as an Acme thread quick coupler.

g. If the propane-gas cylinder comes with a dust plug, place

the dust cap on the cylinder valve outlet whenever the

cylinder is not in use.

QUICK COUPLER OPERATION

To connect the regulator/hose assembly to the propane-

gas cylinder valve fitting: Press the hand nut on the regulator

over the Acme thread fitting on the cylinder valve.Turn the hand

nut clockwise to engage the threads and tighten until snug.

ENCLOSURE REQUIREMENTS

FORYOUR SAFETY, you must provide the openings listed below for replacement air and ventilation of the unit enclosure. One

side of the enclosure shall be left completely open to the outside; OR 4 (minimum) ventilation openings MUST be created:

• Each opening must have a minimum of 10 sq. in. of free area. The openings must be equally sized.

• Two openings must be in the side walls of the enclosure, at the top level, and spaced at a minimum of 90 degrees.The openings

must begin 1" or less below the countertop level and end no more than 5" below the countertop level.

• Two openings must be in the side walls of the enclosure, at the floor level, and spaced at a minimum of 90 degrees.The openings

must begin 1" or less above the floor level and end no more than 5" above the floor level.

• The openings must remain unobstructed: The clearance between the openings and any items outside of the enclosure is

a minimum of 6". The clearance between the openings and any items within the enclosure is a minimum of 2".

It is acceptable to use RHP venting panels (PN 5510-01). Contact your dealer.

KEEP THE REQUIRED VENT OPENINGS AND SURROUNDING AREA OF THE ENCLOSURE CLEAR AND FREE AT ALL TIMES.

WARNING: Ventilation openings in side walls shall not communicate directly with other enclosures of the outdoor cooking gas appliance.

e. The pressure regulator and hose assembly used must

match the specification for Type I by ANSI Z 21.58/CGA

1.6 (see Fig. 5-1).

SAFE USE & MAINTENANCE OF PROPANE GAS CYLINDERS