10

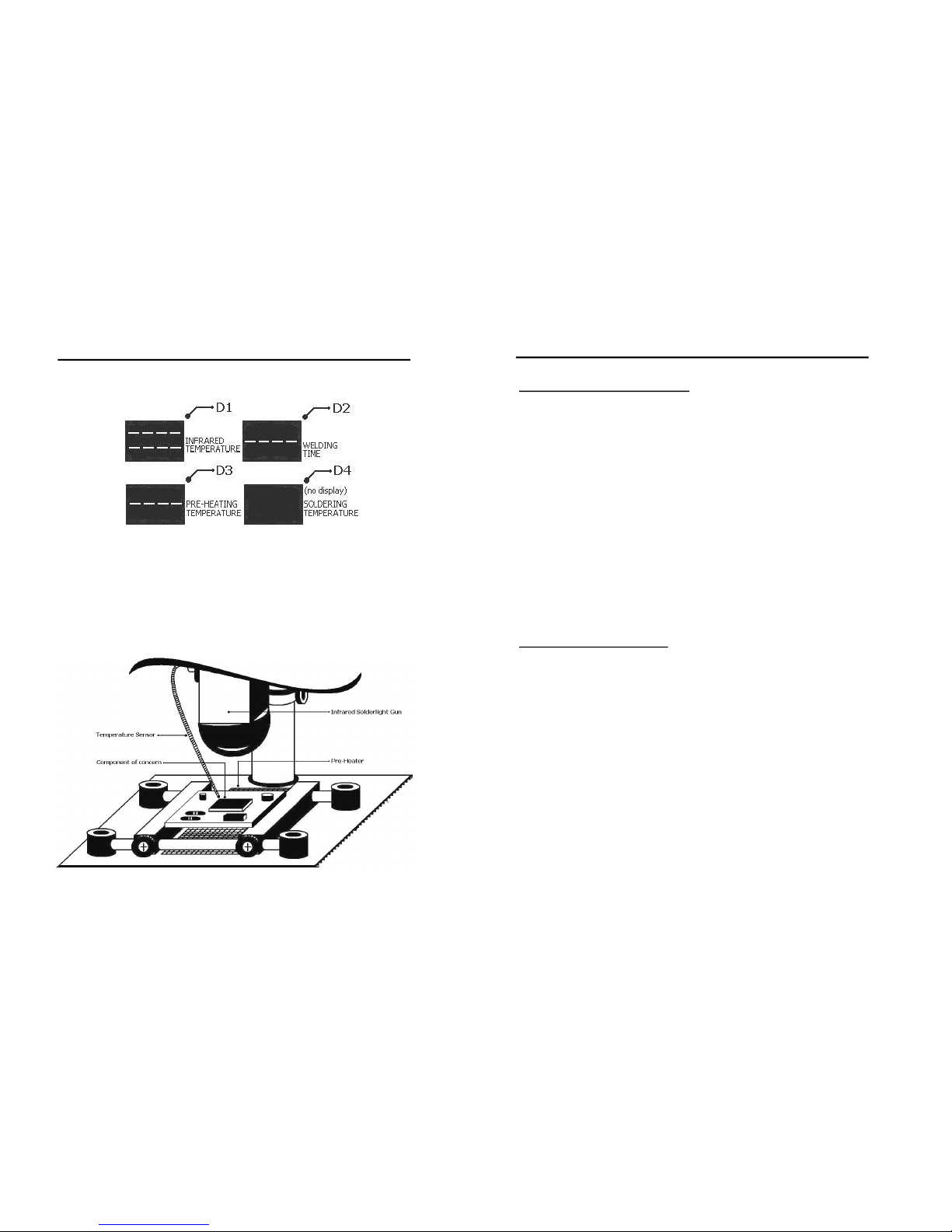

4. WithbuttonsC1,C4,C7,andC10disabled(OFF),thedisplaypan

elswillshowthefollowing.

5. ThePCB/componenttoberepairedshouldbeplacedontopofthe

preheatingcomponent.UsethebeamstoholdthePCBandadjust

the screws to secure the placement. Make sure that the affected

component is placed at an appropriate distance, perpendicular to

the IR solderlight gun. Thiswill keep the IRlight focused only to

the component concerned. Move the temperature sensor tip near

thecomponentfortemperaturereading.

OPERATINGPROCEDURES

15

USINGTHESOLDERINGIRON

1. WiththeunitswitchedONandthesolderingplugconnectedtothe

equipmentviaterminalEfromthecontrolpanel,activatesoldering

bypushingbuttonC10.

2. AdjustthesolderingirontemperatureusingbuttonsC11andC12.

3. Waitforafewsecondswhilethesystemisadjustingthesoldering

irontemperaturetothedesiredvalue.Youwillheara“beep”ora

highpitchsoundwhenthetemperatureisreached.

4. Whenworkisfinished,deactivatesolderingswitch.

5. TurnOFFtheunit.

6. Unplugthedevicefromthemainpowersource.

NOTE: The soldering iron temperature is configurable from 200 to

480C,with350Casthedefault.

USINGTHEFOOTSWITCH

1. Before reworking, make sure the unit is switched ON, the foot

switchconnectedtothedeviceviafootswitchplug,Ffromthecon

trolpanel,thePCBisproperlyplacedontopoftheequipment,and

thepreheattemperatureisreached.

2. Set the temperature by temporarily activating IR welding switch,

C1, and increase or decrease the desired reworking temperature

usingbuttonsC2andC3.

3. Oncetemperatureisset,deactivateC1.

4. Steponthefootswitchtostartreworking.

5. Whenfinished,turnoffthedevice.

6. Unplugtheunitfromthemainpowersource.

OPERATINGPROCEDURES