AP Diving Ltd. RBV07 Swivel Inflator Range Maintenance Manual

Page 2 of 50

Table of Contents

1. Introduction ........................................................................................... 4!

1.1 Functional description .................................................................................... 4!

1.2 Servicing ........................................................................................................ 4!

1.3 Warranty ......................................................................................................... 4!

1.4 Copyright and Applicable Law ........................................................................ 4!

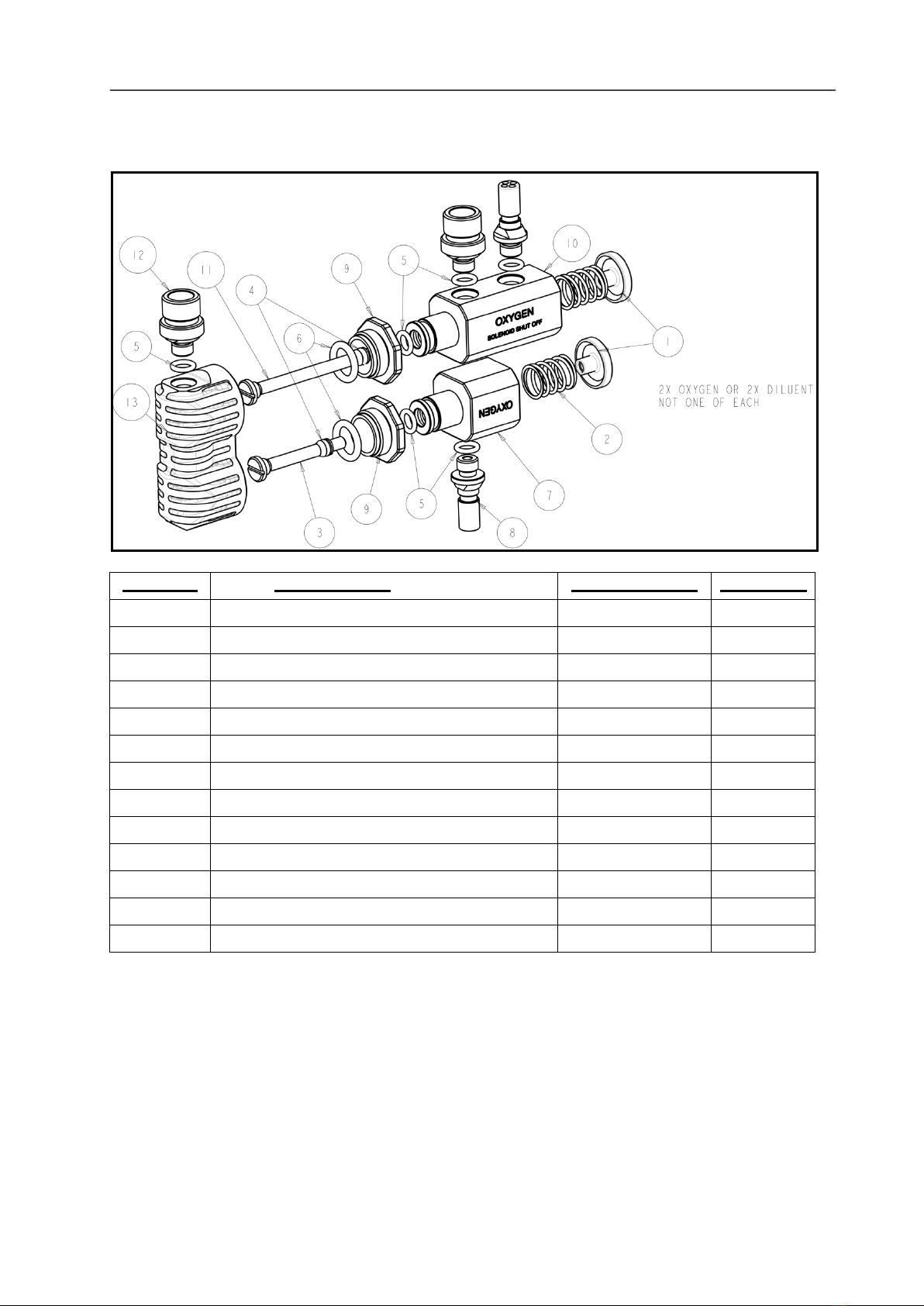

3. RBV07 Swivel Inflator Range Exploded Diagrams and Parts Lists ..... 5!

3.1 RBV07(A) Single Swivel Inflator main assembly ............................................ 5!

3.2 RBV07(A)/DUAL Dual Swivel Inflator main assembly .................................... 6!

3.3 RBV07(A)/SO Single Swivel Inflator with Shutoff Valve main assembly ........ 7!

3.4 RBV07(A)/DUAL/SO Dual Swivel Inflator with Shutoff Valve main assembly 8!

3. General Information .............................................................................. 9!

3.1 Four versions ................................................................................................. 9!

3.2 Gas flow paths ............................................................................................... 9!

3.3 Single Swivel Inflators - RBV07 & RBV07A .................................................... 9!

3.4 Dual Swivel Inflators - RBV07/DUAL & RBV07A/DUAL ............................... 10!

3.5 Single Swivel Inflators with Flowstop Shutoff - RBV07/SO & RBV07A/SO .. 11!

3.6 Dual Swivel Inflators with Shutoff - RBV07/DUAL/SO & RBV07A/DUAL/SO

........................................................................................................................... 12!

3.7 Recommended Position of the Collar of the GC3 Flowstop ......................... 13!

4. Service Kit Contents and Tools .......................................................... 14!

4.1 Service Kit Contents ..................................................................................... 14!

4.2 Tools Needed ............................................................................................... 15!

5. Disassembly Instructions .................................................................... 16!

5.1 General overview: main disassembly steps ................................................. 16!

5.2 Unscrew the 5/16” inflator stem(s) from the inflator body ............................. 16!

5.3 Unscrew the GC3 Flowstop isolator from the 5/16”-9/16” adapter ............... 17!

5.4 Unscrew the 5/16”-9/16” adapter(s) from the outlet body or inflator body .... 18!

5.5 Remove the inflator body from the outlet body ............................................. 19!

5.6 Unscrew the blue or green push button from the inflator spindle ................. 21!

5.7 Remove the O-ring from the inflator body .................................................... 23!

5.8 Remove low profile counterlung inlet elbow from counterlung ..................... 26!

5.9 Remove O-rings from MP counterlung inflator hose..................................... 27!

5.10 When GC3 Flowstop is fitted: remove O-rings from both ends of MP hose27!

AP50 Medium Pressure (MP) hose disassembly ............................................... 28!

5.11 Remove circlip from snap connector body ................................................. 28!

5.12 Remove sliding collar from snap connector body ....................................... 28!

5.13 Remove spring from snap connector body ................................................. 28!

5.14 Remove 4 ball bearings from snap connector body ................................... 29!

5.15 Unscrew Schraeder valve from snap connector body ................................ 29!

5.16 Remove O-ring from snap connector body ................................................. 30!

6. Clean and Replace Service Parts ....................................................... 31!

6.1 Ultrasonically clean deposits from all metal parts ......................................... 33!

6.2 Replace all O-rings with new ones from the Service Kit ............................... 34!

6.3 How to lightly grease O-rings ....................................................................... 34!

7. Assembly Instructions ......................................................................... 36!

7.1 General overview: main assembly steps ...................................................... 36!