2. Prompts of operating technologies:

2.1. During operation, align with the front LED of the product (the distance is not more than 1m), press the

unlock key at first, then press the corresponding functional keys to set, and the red light flashes when the key is

pressed.

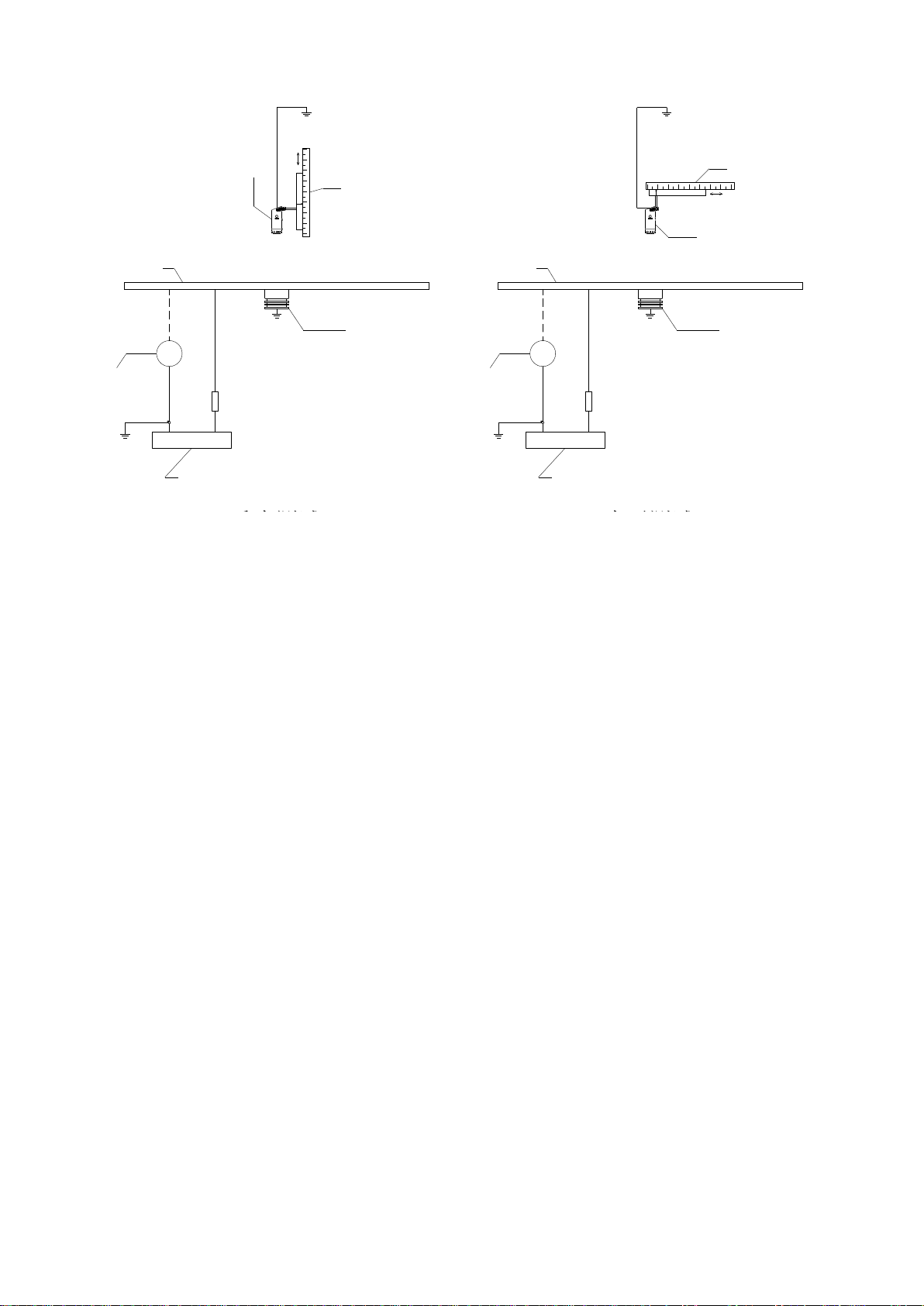

2.2. During zeroing setting, the calibration plate should be much larger than the detection window of sensor, and

the polar plate and sensor should be well grounded.

2.3. During the calibration operation, the calibration plate should be much larger than the detection window of

sensor and the sensor should be well grounded.

2.4. There should be no shield between the sensor and the detected object; otherwise the accuracy of the

detection result will be affected.

2.5. There should be no electrical equipment that may affect the sensor within the detection range of the sensor.

2.6. To accurately measure the charged object, the plane of the sensor detection window must be parallel to the

surface of the detected object.

2.7. When the charged object is smaller than the calibration plate, the measured value will be smaller than the

actual electrostatic value of the charged object.

2.8. When the charged object is larger than the calibration plate, the measured value will be larger than the

actual electrostatic value of the charged object.

2.9. Do not set zero in electrostatic charge state or in the electrostatic measurement process (non-static

calibration process); if zero clearing is made during the electrostatic test, the displayed electrostatic value will

be zero.

2.10. Influence of temperature and humidity on electrostatic detection:

The lower the temperature is, the smaller the humidity is, the less water is contained in the space, and the

more easily the surrounding object triboelectric and the greater the interference to the electrostatic

detection is.

1) The higher the temperature is, the higher the humidity is, the more water is contained in the space,

and the more active the movement of water molecules is, which is easy to produce corona or spark

discharge to the calibration device and the greater the influence on the uniform electric field generated by

the calibration device, the weaker the uniform electric field will be.

2) Under the same humidity, the lower the temperature is, the less water is contained in the space, and

the more easily the surrounding object triboelectric and the greater the influence on the electrostatic

detection is.

Therefore, during electrostatic calibration/detection, the environmental temperature and humidity should be

clearly indicated during calibration/detection.

2.11. Due to the existence of the cosmic rays and micro-radioactive substance in the environment as well as the

use of various kinds of electrical equipment, there are inevitably more or less positive and negative irons in the

detection space, which may also have certain impact on the detection results.

3.Display information of monitoring terminal

Working status: whether the sensor works normally and has alarm output.

Equipment address: display the address set by the sensor.

Detection distance: display the detection distance set by the sensor.

Threshold voltage: display the set safety (alarm) threshold of static voltage.

Real time voltage: display the static voltage value on the surface of the measured object.