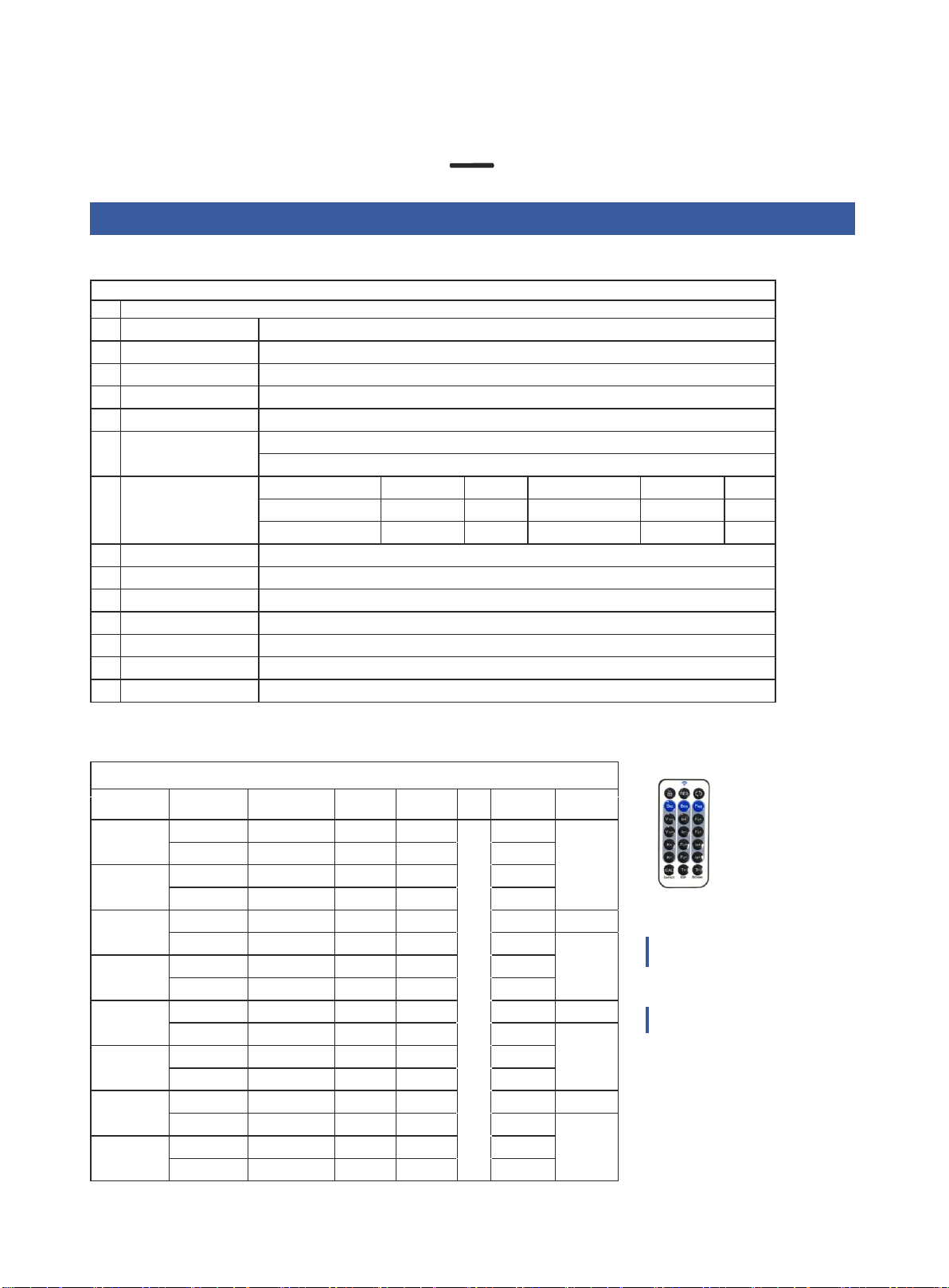

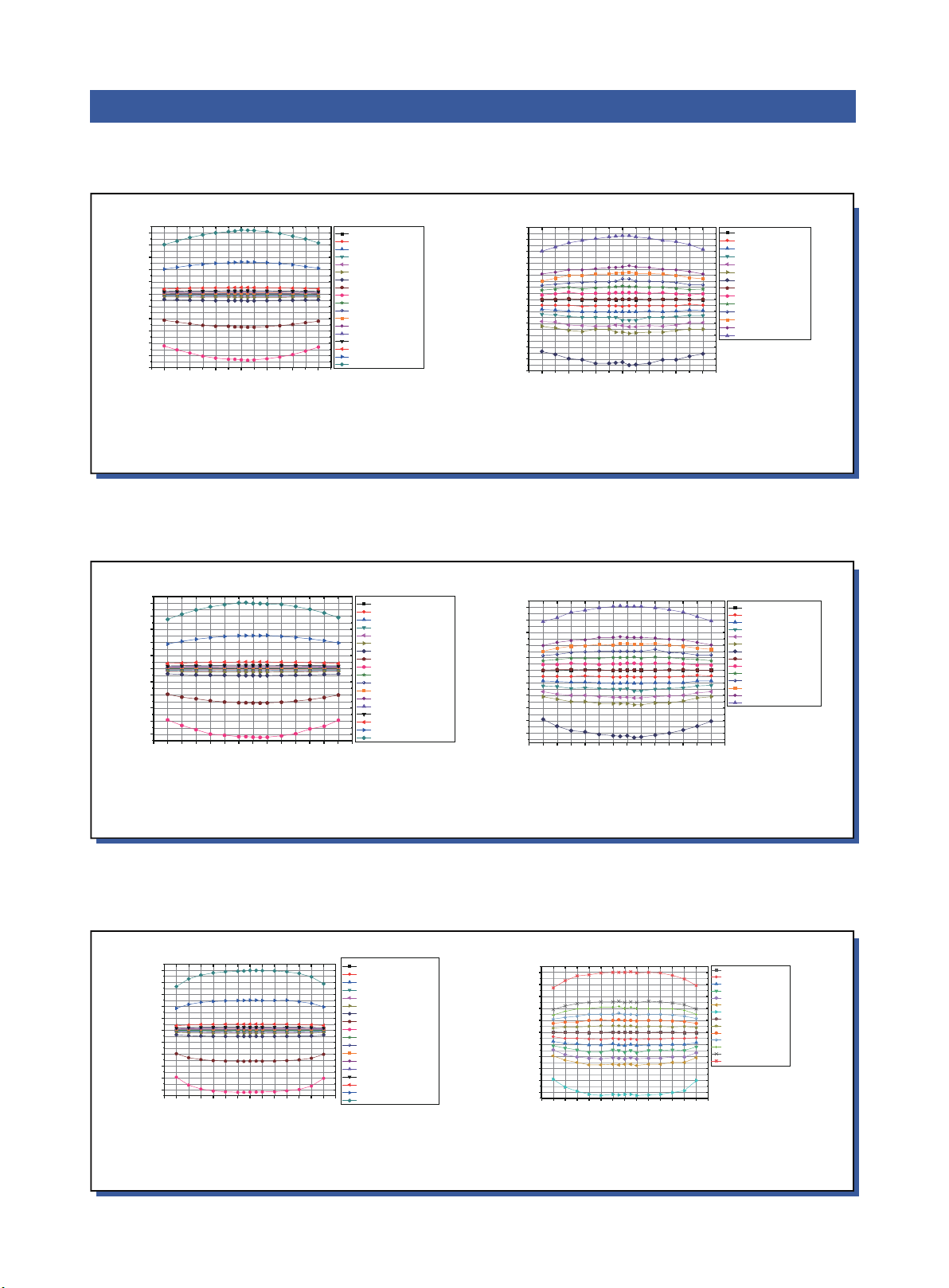

Calibration plate voltage-0V

Calibration plate voltage-100V

Calibration plate voltage-200V

Calibration plate voltage-300V

Calibration plate voltage-400V

Calibration plate voltage-500V

Calibration plate voltage-1000V

Calibration plate voltage-5000V

Calibration plate voltage-10000V

Calibration plate voltage+0V

Calibration plate voltage+100V

Calibration plate voltage+200V

Calibration plate voltage+300V

Calibration plate voltage+400V

Calibration plate voltage+500V

Calibration plate voltage+1000V

Calibration plate voltage+5000V

Calibration plate voltage+10000V

-300 -200 200 300

-12000

-10000

-8000

-6000

-4000

-2000

0

2000

4000

6000

8000

10000

8QGHUWKHFRQGLWLRQRIWKHYHUWLFDOWHVWGLVWDQFHRIPP

WDNHWKHFHQWHUSRLQWRIWKHFDOLEUDWLRQSODWHDVWKHFRRUGLQDWH

RULJLQDQGPRYHWKHVHQVRUKRUL]RQWDOO\IRUWHVWLQJ

The test voltage value of the sensor(V)

-1000 100

-300 -200 -100 0 100 200 300

-1200

-1000

-800

-600

-400

-200

0

200

400

600

800

1000

1200

8QGHUWKHFRQGLWLRQRIYHUWLFDOWHVWGLVWDQFHRIPP

WDNHWKHFHQWHUSRLQWRIWKHFDOLEUDWLRQSODWHDVWKHFRRUGLQDWH

RULJLQPRYHWKHVHQVRUKRUL]RQWDOO\IRUWHVWLQJ

Horizontal test distance(mm)

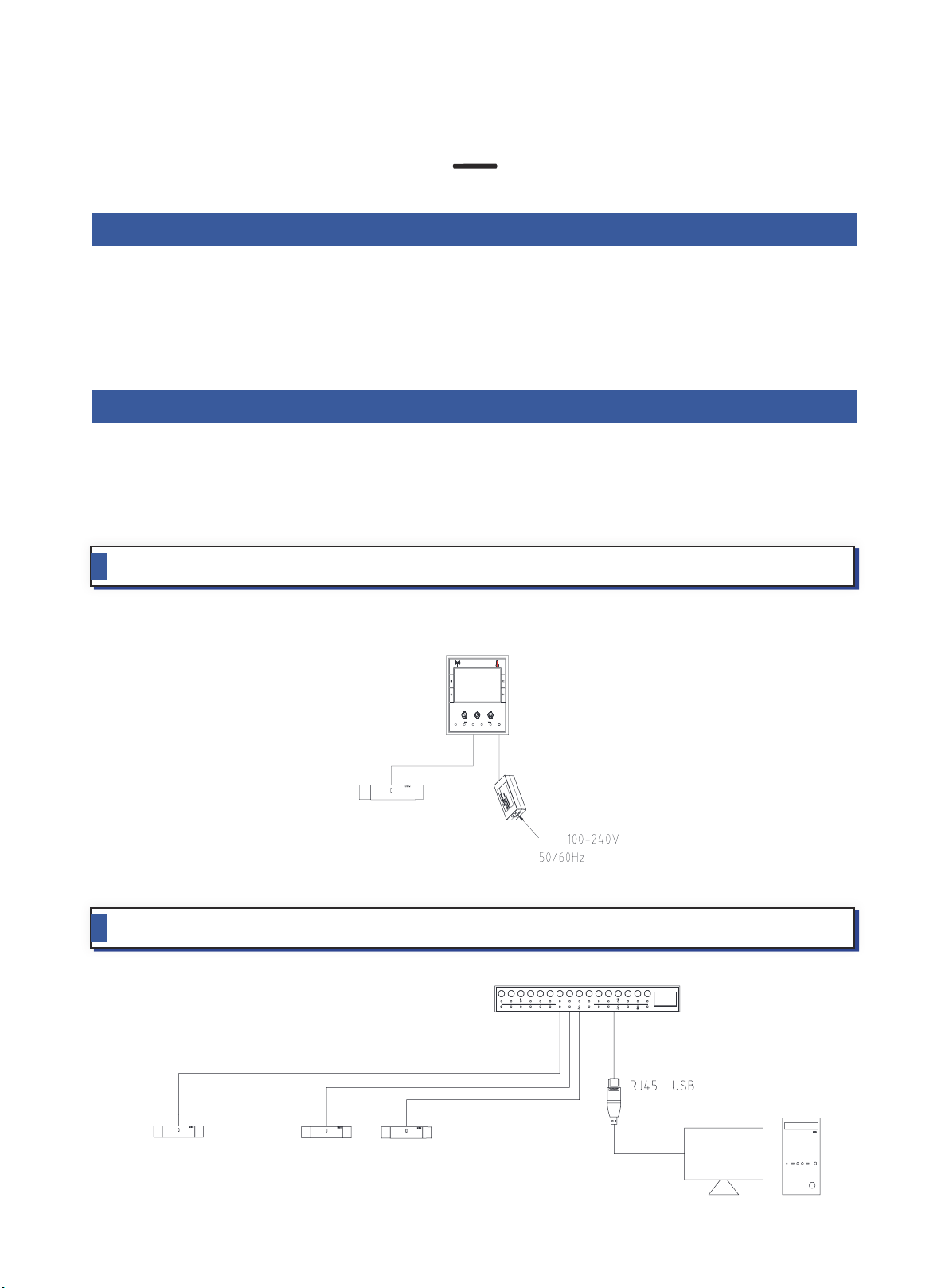

Calibration plate voltage-0V

Calibration plate voltage-100V

Calibration plate voltage-200V

Calibration plate voltage-1000V

Calibration plate voltage+0V

Calibration plate voltage+500V

Calibration plate voltage+1000V

-350 -300 -250 -200 -150 -100 -50 05 0 100 1502 00 2503 00 350

-10000

-8000

-6000

-4000

-2000

0

2000

4000

6000

8000

10000

-350 -300 -250 -200 -150 -100 -50 05 0 100 150 200 250 300 350

-1000

-800

-600

-400

-200

0

200

400

600

800

1000

Calibration plate voltage-0V

Calibration plate voltage-100V

Calibration plate voltage-200V

Calibration plate voltage-300V

Calibration plate voltage-400V

Calibration plate voltage-500V

Calibration plate voltage-1000V

Calibration plate voltage+0V

Calibration plate voltage+100V

Calibration plate voltage+200V

Calibration plate voltage+300V

Calibration plate voltage+400V

Calibration plate voltage+500V

Calibration plate voltage+1000V

-350 -300 -250 -200 -150 -100 -50 05 01 00 1502 00 2503 00 350

-10000

-8000

-6000

-4000

-2000

0

2000

4000

6000

8000

10000

-350 -300 -250 -200 -150 -100 -50 05 0 100 150 200 250 300 350

-1000

-800

-600

-400

-200

0

200

400

600

800

1000

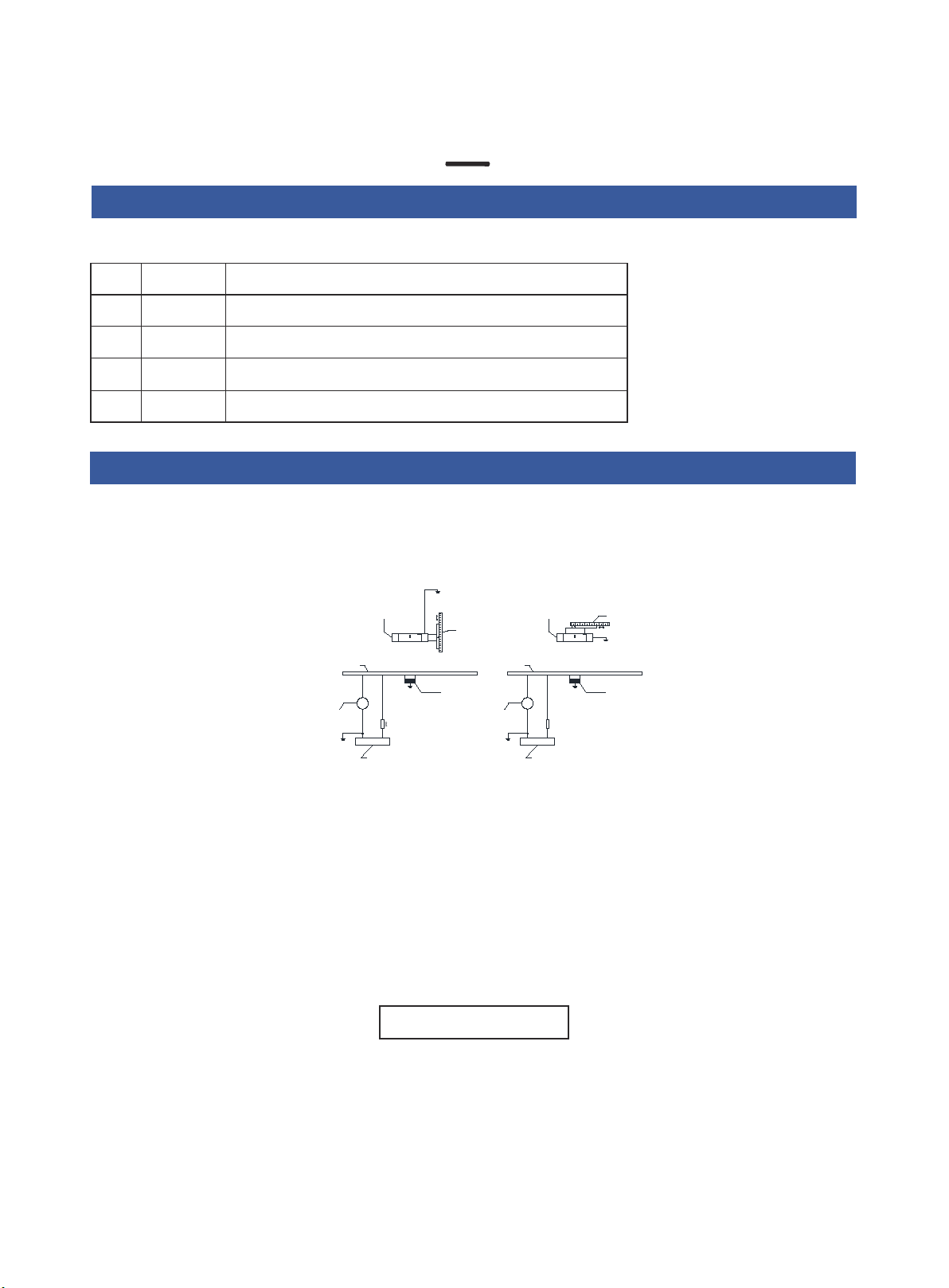

The horizontal test data of the sensor and the standard plate electrode are as follows:

Figure 11-1 the horizontal test data of standard plate electrode at a vertical distance of 500mm Figure 11-2 the horizontal test data of standard plate electrode at a vertical distance of 500mm

① Figure 11 shows the test data at different horizontal test distances under a vertical test distance of 500mm, the standard plate electrode of

600mm*600mm stainless steel electrode, and the sensor with the center position of the calibration plate as the coordinate origin:

② Figure 12 shows the test data at different horizontal test distances under a vertical test distance of 300mm, the standard plate electrode of

600mm*600mm stainless steel electrode, and the sensor with the center position of the calibration plate as the coordinate origin:

③ Figure 12 shows the test data at different horizontal test distances under a vertical test distance of 100mm, the standard plate electrode of

600mm*600mm stainless steel electrode, and the sensor with the center position of the calibration plate as the coordinate origin:

It can be seen from the above two horizontal test charts that the measurement error of the sensor can be kept within 5% within the horizontal

distance range of -200mm≤X≤200mm under the vertical test distance of 500mm for the 600*600mm calibration plate.

It can be seen from the above two horizontal test charts that the measurement error of the sensor can be kept within 5% within the horizontal

distance range of -200mm≤X≤200mm under the vertical test distance of 300mm for the 600*600mm calibration plate.

It can be seen from the above two horizontal test charts that the measurement error of the sensor can be kept within 5% within the horizontal

distance range of -200mm≤X≤200mm under the vertical test distance of 100mm for the 600*600mm calibration plate.

The test voltage value of the sensor(V)

Horizontal test distance(mm)

Calibration plate voltage+100V

Calibration plate voltage-300V

Calibration plate voltage-400V

Calibration plate voltage-500V

Calibration plate voltage+200V

Calibration plate voltage+300V

Calibration plate voltage+400V

Horizontal test distance(mm)Horizontal test distance(mm)

Horizontal test distance(mm)Horizontal test distance(mm)

Figure 12-1 the horizontal test data of standard plate electrode at a vertical distance of 300mm Figure 12-2 the horizontal test data of standard plate electrode at a vertical distance of 300mm

Figure 13-1 the horizontal test data of standard plate electrode at a vertical distance of 100mm Figure 13-2 the horizontal test data of standard plate electrode at a vertical distance of 100mm

The test voltage value of the sensor(V)

The test voltage value of the sensor(V)

The test voltage value of the sensor(V)

The test voltage value of the sensor(V)

8QGHUWKHFRQGLWLRQRIWKHYHUWLFDOWHVWGLVWDQFHRI3PP

WDNHWKHFHQWHUSRLQWRIWKHFDOLEUDWLRQSODWHDVWKHFRRUGLQDWH

RULJLQDQGPRYHWKHVHQVRUKRUL]RQWDOO\IRUWHVWLQJ

8QGHUWKHFRQGLWLRQRIYHUWLFDOWHVWGLVWDQFHRI3PP

WDNHWKHFHQWHUSRLQWRIWKHFDOLEUDWLRQSODWHDVWKHFRRUGLQDWH

RULJLQPRYHWKHVHQVRUKRUL]RQWDOO\IRUWHVWLQJ

8QGHUWKHFRQGLWLRQRIWKHYHUWLFDOWHVWGLVWDQFHRI1PP

WDNHWKHFHQWHUSRLQWRIWKHFDOLEUDWLRQSODWHDVWKHFRRUGLQDWH

RULJLQDQGPRYHWKHVHQVRUKRUL]RQWDOO\IRUWHVWLQJ

8QGHUWKHFRQGLWLRQRIYHUWLFDOWHVWGLVWDQFHRI1PP

WDNHWKHFHQWHUSRLQWRIWKHFDOLEUDWLRQSODWHDVWKHFRRUGLQDWH

RULJLQPRYHWKHVHQVRUKRUL]RQWDOO\IRUWHVWLQJ

Calibration plate voltage-0V

Calibration plate voltage-100V

Calibration plate voltage-200V

Calibration plate voltage-300V

Calibration plate voltage-400V

Calibration plate voltage-500V

Calibration plate voltage-1000V

Calibration plate voltage-5000V

Calibration plate voltage-10000V

Calibration plate voltage+0V

Calibration plate voltage+100V

Calibration plate voltage+200V

Calibration plate voltage+300V

Calibration plate voltage+400V

Calibration plate voltage+500V

Calibration plate voltage+1000V

Calibration plate voltage+5000V

Calibration plate voltage+10000V

Calibration plate voltage-0V

Calibration plate voltage-100V

Calibration plate voltage-200V

Calibration plate voltage-300V

Calibration plate voltage-400V

Calibration plate voltage-500V

Calibration plate voltage-1000V

Calibration plate voltage-5000V

Calibration plate voltage-10000V

Calibration plate voltage+0V

Calibration plate voltage+100V

Calibration plate voltage+200V

Calibration plate voltage+300V

Calibration plate voltage+400V

Calibration plate voltage+500V

Calibration plate voltage+1000V

Calibration plate voltage+5000V

Calibration plate voltage+10000V

Calibration plate voltage-0V

Calibration plate voltage-100V

Calibration plate voltage-200V

Calibration plate voltage-300V

Calibration plate voltage-400V

Calibration plate voltage-500V

Calibration plate voltage-1000V

Calibration plate voltage+0V

Calibration plate voltage+100V

Calibration plate voltage+200V

Calibration plate voltage+300V

Calibration plate voltage+400V

Calibration plate voltage+500V

Calibration plate voltage+1000V