Apeks AP5920 User manual

Issue 05

07/02/2019

AP5920

DRY-SUIT VALVE

OPERATION, CARE

AND USER MANUAL

Tel: +44 (0)1254 692200

Fax: +44 (0)1254 692211

Website: apeksdiving.com

Apeks Marine Equipment Ltd

Neptune Way

Blackburn

Lancs

BB1 2BT

England

Part Number: AP5920

Issue Number: 05

1

Valve Positioning ............................................................. 2

Valve Fitting Procedure.................................................... 3

Inflation Valve Connections ........................................... 4

Hose Connections ............................................................ 4

Suit Valve Operation......................................................... 4

Care and Maintenance..................................................... 5

Suit Valve Range ............................................................... 6

P-Valve, Positioning, Fitting and Operation ................. 7

Guarantee .......................................................................... 8

CONTENTS

2

DRY-SUIT VALVE OPERATION, CARE AND MAINTENANCE MANUAL

VALVE POSITIONING

Auto Dump Valve

It is recommended that the auto dump valve is tted high up on the left or right

arm. With the forearm raised to a horizontal position across the chest, the

dump valve should be directly on top of the upper arm where it can operated

easily by the opposite hand.

Cuff Dump Valve

As the name suggests, the cuff dump valves are tted near the cuff of the

suit. Ensure the valve will not be covered by gloves when tted.

Suit Inflation Valve

It is not critical to the operation of the valve where it is tted on the suit as

it is with the dump valve, but generally the ination valve is tted on the

chest area where it can easily be reached. When positioning the valve try to

ensure that it won’t be covered by other pieces of diving equipment, affecting

access to the valve.

Rubber Backing Patch

It is highly recommended that a rubber backing patch (Apeks part# AP0166)

is bonded to the outside of the suit with a suitable adhesive, where both

ination and dump valves are to be positioned. If the hole for the valve has not

been cut previously then carefully cut out the suit in the centre of the rubber

backing patch. If a backing patch is not tted, this could result in a leak.

RG91112 8

AT43 AT105

RG912220

3

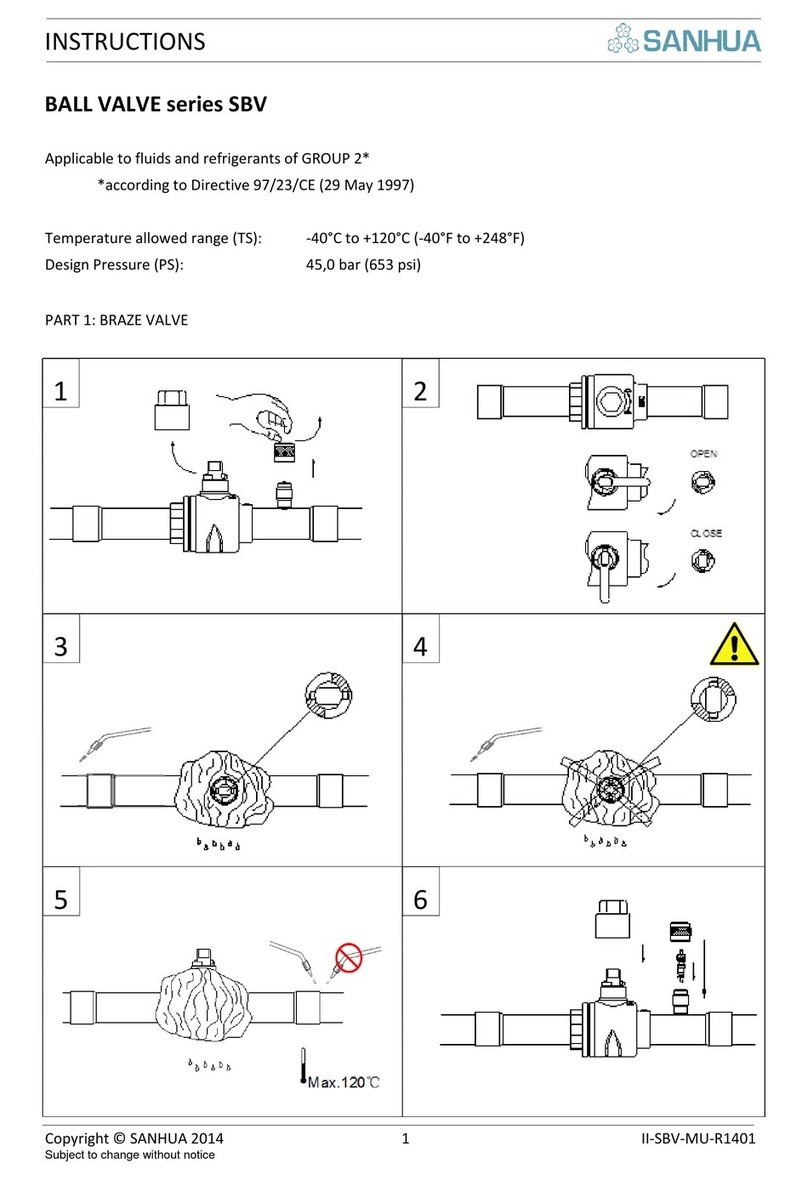

VALVE FITTING PROCEDURE

Low Profile Auto Dump Valve Fitting

When the rubber backing patch has been bonded to the suit and the hole

cut out, the valve is ready to be tted. Place the thread of the valve through

the hole in the suit, ensuring the retaining ring of the dump valve is located

correctly around the cap (Fig. 1).

VERY IMPORTANT: Before any torque is applied to the locking nut or

dump valve it is critical that the adjusting cap of the dump valve is

pressed down to lock the valve mechanism. (Fig 2) Failure to press the

cap during tightening or loosening of the valve, could cause damage

to the mechanism.

The valve should be tightened into the suit to approx. 4 lbs/ft (5.4 Nm)

using AT43 tool or as tight as possible by hand. Apply the torque to

the backing nut and you will find the dump valve will tend not to rotate

due to the friction on the rubber backing patch.

After a few days or before you dive re-check the tightness of the

backing nut.

WARNING: Periodically check all the valves to ensure they are still

tight in the suit.

Figure 1

Retaining

ring

Rubber

Backing

Patch

Locking

Nut

Figure 2

IMPORTANT:

PRESS

DOWN THE

CAP

WHILE

TIGHTENING

THE

LOCKING

NUT

Screw the locking ring onto the dump valve until the valve is tightly held in the suit.

Fitting all other suit valves

Including: standard dump valve, cuff dump valve (AT43 tool can be used) and

all ination valves.

All other suit valves are tted in the same way as the low prole dump valves

shown previously, but without the need to press down on the front of the valve.

You will nd with the swivel ination valve, that it rotates through approximately

350 degrees and then stops, this stop is to enable the valve to be tightened into

the suit. When the valve is tight in the suit, you should ensure that the stop is not

in the area you wish the valve to swivel.

4

DRY-SUIT VALVE OPERATION, CARE AND MAINTENANCE MANUAL

INFLATION VALVE CONNECTIONS

There are two types of ination

valve connections used.

Fig. 3 shows the Apeks tting

and Fig. 4 shows the Seatec

tting. The Seatec tting is the

same tting foundon buoyancy

device direct feeds and tends

to be more widely used.

HOSE CONNECTIONS

There are two types of hose

coupling to go with the ination

valve connections. Again these

are Apeks couplings (Fig 5) and

Seatec couplings (Fig 6).

The difference in tting is, the

Apeks coupling will just push

straight ontothe ination valve connection, but theSeatec coupling needs tohave

the collar on the coupling pulled back while pushing it onto the valve connection.

The hoses come with a standard 3/8” UNF male thread so they can be tted

to the medium pressure port of any 1st stage regulator.

When tting the hose to the regulator, ensure the O-ring is lightly lubricated

and tighten the hose using a 9/16” A/F spanner.

Longer hoses are available to special order from your local Apeks dealer.

Figure 3 Figure 4

SUIT VALVE OPERATION

Inflation and Auto Dump Valves

Including: standard dump valve and low prole dump valve.

Before each dive, it is advisable to check the tightness of the suit valves in the suit

to ensure leak free diving.

1. Do not dive over-weighted. Choose a safe shallow place to test your buoyancy.

2. Always enter the water with the dump valve approximately half closed, in

the event of an emergency, you may need immediate positive buoyancy.

3. Once in the water, on the surface, blow sufficient air into your suit, by depressing

the button on the suit ination valve, to provide strong positive buoyancy.

4. Fully deflate your buoyancy jacket. If you cannot maintain positive buoyancy

with the dump valve approximately half closed, you are probably over weighted.

Figure 5 Figure 6

Pull collar

back while

fitting to

valve

5

5. To submerge, firmly press the adjustable cap of the dump valve to operate

the manual dump system. If you cannot submerge easily after venting all the air

from the suit, you are under weighted.

6. Settle yourself comfortably on the bottom, in an upright position. Wind open

the dump valve cap completely, blow air into your suit until it vents from the dump

valve, close the dump valve cap one or two clicks at a time and press the inator

again. Repeat until sufcient buoyancy can be achieved to maintain a controlled

rate of ascent without any assistance. As you ascend, expanding air within the suit

will be automatically vented. You may stop or slow down your ascent at any time

by operating the manual push dump system. You should practice this procedure

several times in progressively deeper water until you are thoroughly familiar with

the valves’ capabilities.

Cuff Dump Valves

When using cuff dump valves, venting of the air is done simply by raising

the arm and allowing the air to rise venting through the cuff dump valve. This

type of valve is simpler than the auto dump valve, but does not offer the same

control of buoyancy.

CARE AND MAINTENANCE

Suit Inflation Valves

The suit ination valve should be rinsed in fresh water after use, it should then

be connected to the air supply and blown through to clear any residual water.

The valve should be stripped down, cleaned and the O-rings changed annually

to guarantee trouble free operation.

All Dump Valves

The dump valve should be rinsed in fresh water after use and then the residual

water gently shaken off.

Check the operation of the valve before each dive.

VERY IMPORTANT: When removing the low profile auto dump valve

ensure the adjusting cap is depressed while loosening as described

on page 5. Failure to depress the cap could cause damage to the

valve mechanism.

VERY IMPORTANT: Any work carried out on the suit valves should

always be done by a competent service technician.

6

DRY-SUIT VALVE OPERATION, CARE AND MAINTENANCE MANUAL

APEKS DRY SUIT VALVE RANGE

Swivel suit inflation valve

TL115123—Apeks fitting

TL115139—Seatec fitting

Seatec fitting Low Profile

Auto Dump Valve

TL113128

Cuff Dump Valve

TL112112

Auto Dump Valve

TL111115

P-Valve

TL116001

7

CAUTION: Take care to prevent slipping and damaging the suit.

P-VALVE

Valve positioning

As with the suit ination valve, the siting of the P valve is not critical. The most

common area for positioning is the inner thigh. Ensure that you can reach the

valve easily to rotate the valve cap and open the valve.

Valve fitting

If the hose of the P-valve is too long, it can be trimmed to suit a preferred

location. To t the P-valve, a 26mm diameter hole must be cut into the dry suit.

The rubber backing patch is aligned with the newly cut hole and glued to the

outside of the dry suit, using suitable contact adhesive. Allow to dry.

Remove the grub screw from valve cap using 1.25mm Allen key.

Unscrew valve cap and nut from valve body.

From the inside of the suit insert valve body through hole and screw on nut.

Tighten using multi tool AT105 (5 Nm max).

Screw valve cap fully down onto the valve body.

Insert grub screw into the valve body and fully screwing using 1.25mm Allen

key, then unscrew grub screw 2 full turns.

The valve cap should rotate approx. 120 degrees between closed and fully open.

P-Valve operation

To open the valve, rotate the cap anti-clockwise until it stops. In this position the

valve can be used throughout the dive without the need for further adjustment,

as it uses a non return valve system. For extra security the valve can be closed

when not being used. To close the valve, rotate the cap clockwise, excessive

force is not required.

CAUTION: Ensure that the hole is sufficiently clear from any seals/seams.

CAUTION: Position the valve so that the hose and connection will point

in the desired direction.

WARNING: It is recommended that all APEKS suit valves are installed

by an experienced drysuit technician.

8

DRY-SUIT VALVE OPERATION, CARE AND MAINTENANCE MANUAL

Cleaning and maintenance

The P-Valve must be rinsed and ushed through with clean fresh water after

every dive. This is important to maintain trouble free use and due to bacterial

growth and the potential health implications.

GUARANTEE

As with all Apeks valves, our range of dry-suit valves come with a lifetime

guarantee to the original owner, against defects in materials and workmanship.

This guarantee does not cover damage due to abuse, neglect, improper usage,

lack of maintenance or normal wear and tear.

If after inspection by Apeks, we are satised that the product is defective, the

product will be repaired or replaced free of charge.

SERVICING

It is recommended that all Apeks suit valves are inspected on a yearly basis.

Every two years your valves should be serviced by your local Apeks dealer

or suit manufacturer.

CAUTION: Diving is a potentially hazardous sport. Before using any

diving equipment you should be properly trained in the use of the

equipment by a recognised club or organisation.

All Apeks diving equipment is designed and manufactured in England and is

guaranteed and backed by a rst class after sales service. When your equipment

requires any service or should need repair, you should rst contact your local

Apeks dealer or the suit manufacturer. If dealer service is not available, you

can contact our customer service department directly.

Thank you for purchasing Apeks Dry-suit valves.

DRY-SUIT VALVE

OPERATION, CARE

AND USER MANUAL

Apeks Marine Equipment Ltd

Neptune Way, Blackburn, Lancashire,

England, United Kingdom, BB1 2BT

Tel: 00 44 (0)1254 692200

apeksdiving.com

Table of contents

Popular Control Unit manuals by other brands

SKUTCH

SKUTCH CK-1P9 manual

Honeywell

Honeywell VGF installation instructions

Thonk

Thonk Spring Reverb instructions

Triax

Triax CSE 816 Assembly instruction

Texas Instruments

Texas Instruments TMS320C6A816 Series Technical reference manual

UTC Fire and Security

UTC Fire and Security interlogix VR1500 Installation & operation instructions