Apex Digital EK76 User manual

www.apexanalog.com

Subject to Change

© Apex Microtechnology Inc.

All rights reserved

May 2020

EK76U Rev A

Evaluation Kit

EK76

APPLICABLE PARTS (SOLD SEPARATELY)

• SA310KR

INTRODUCTION

This kit contains everything needed for rapid prototyping with the SA310KR 3-phase driver. With a multi-

tude of circuit options, the EK76 offers versatility when in comes to connecting inputs, measuring outputs,

and conditioning signals to the specific application environment. High- and low- input signals for each phase

may be supplied from any 3 V to 18 V digital controller via standard pin header or SMA connectors. A remov-

able 50 Ω termination resistor is offered for impedance-matched inputs. Coaxial measurement points are

offered for high-fidelity waveform measurement, so erroneous overshoot/ringing are cut down to a mini-

mum. The layout is carefully optimized for signal and power transmission, while permitting easy integration

with system controllers and 3-phase loads.

ABSOLUTE MAXIMUM RATINGS

All specifications listed in the SA310 datasheet apply to this board, except as noted below. This board

uses components that limit SA310's full operating range in exchange for convenience to the customer.

Parameter Symbol Max Units Limited By

Output Current, continuous, within SOA IOUT 20 A DUT-socket

Power Dissipation, SA310 PD60 W DUT-HS

EK76

2 EK76U Rev A

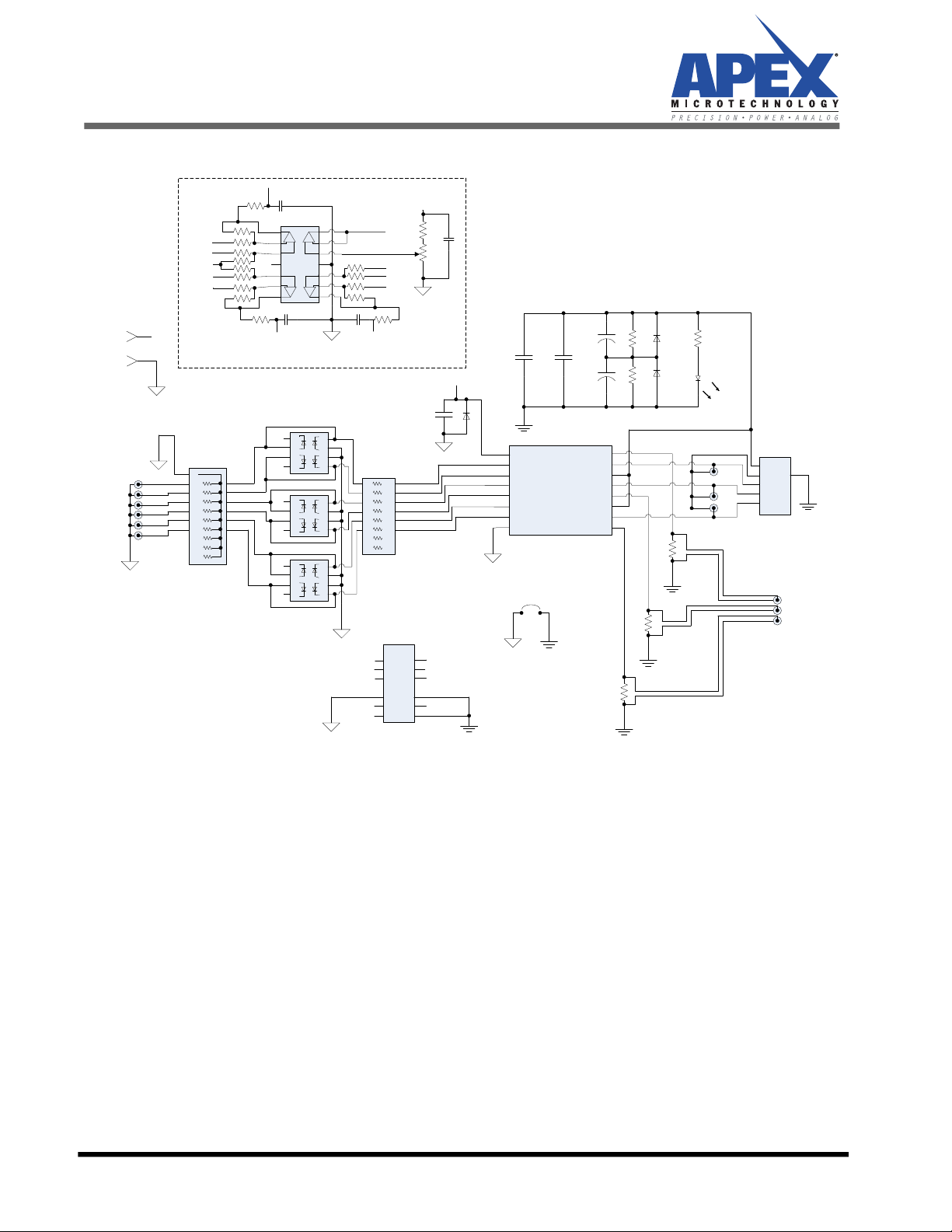

Figure 1: Circuit Diagram

DUT

Vcc

INW_HS

INW_LS

INV_HS

INV_LS

INU_HS

INU_LS

DGND

PGND_W

OUT

_W

+

VS_VW

OUT

_V

PGND

_V

+

VS_U

OUT

_U

PGND

_U

R3

HS

,CSR

R2

HS

,CSR

R1

HS

,CSR

+Vs

PGND

W

V

U

P5

P3

P4

8

7

6

5

4

3

2

1

IMON_V

IMON_U

IMON_W

9

10

11

12

13

14

15

16

INW_H

INW

_L

INV

_H

INV

_L

INU

_H

INU

_L

P14

P

13

P

12

P

11

P

10

P

9

P8

P7

P6

P1

1

3

5

7

9

11

13

15

2

4

6

8

10

12

14

16

INU_H

INV

_H

INW

_H

IM

_U

IM

_W

INU_L

INV

_L

INW

_L

IM

_V

P2

V

CC

CBP1 D1

CBP3CBP2

CBP5

CBP4 R4

R5

D2

D3

1

2

3

4

5

6

7

8

9

10

R6-

socket

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

R7

J1

Press-Fit Sockets –

90

mil PTH ±2 mil

+

+

R8

LED1

VCC

P16

P15

DGND PGND

8

7

6

5

1

2

3

4

VCC

VCC

8

7

6

5

1

2

3

4

VCC

VCC

8

7

6

5

1

2

3

4

VCC

VCC

R9

+

-

+

-

+

-

+

-

V+ V-

1

2

3

4

5

6

7

14

13

12

11

10

9

8

R10

R11

R12

R17

R18

R19

R20

R14

R15

R16

R13 VCC

R21

R22

VCC

BIAS

BIAS

BIAS

GNDU

IMONU

IMONV

GNDV GNDW

IMONW

R24 C2

CURRV

CURRU

R23 C1

R25

C3

CURRW

C4

U1

D4

D5

D6

OPTIONAL CURRENT SENSE CIRCUIT

EK76

EK76U Rev A 3

PARTS LIST

Reference Manufacturer Part # Description QTY

Printed Circuit Board

EVAL94 EVAL94 Printed Circuit Board 1

Resistors

R1, 2, 3 CSR03 Res, 10mΩ, 16W, 5%, TO-220 3

R4,5 CFR-50JB-52-430K Res, 430kΩ, 1/2W, 5%, Axial 2

R6 4610X-101-510LF Res, 9 array, 51Ω, 0.2W, SIP 1

R6-socket PPTC101LFBN-RC SIP Socket, 10pin 1

R7 4116R-1-221LF Res, 8 array, 220Ω, TH DIP 1

R8 RR03J150KTB Res, 150kΩ, 3W, 5%, Axial 1

Capacitors

CBP1 OX7RR105KWN Ceramic Cap, 1 µF, 200V 1

CBP2, 3 2220Y1K00474KXTWS2 Ceramic Cap, 470nF, 1KV, X7R, 2220 2

CBP4, 5 380LX122M400A082 Electrolytic Cap, 1200µF, 400V 2

Diodes

D1 P6KE27A-TP TVS diode, 23.1V standoff, 5W 1

D2, 3 P6KE400A TVS diode, 342V standoff, 5W 2

D4, 5, 6 UC3611N Diode, 4 array, 50V, 3A 3

LED1 LTL2R3KRD-EM LED, red, 2mA nominal 1

Hardware

DUT-socket 6342-0-15-15-42-27-10-0 Pin Receptacle, 20A 16

P1 TS01 5-Block Terminal Strip 1

P2 M20-9980845 Pin header, 2 x 8, 0.1" pitch 1

P3, 4, 5 731711900 BNC connector, vertical, PC mount 3

P15, 16 571-0100 Banana Jack, horizontal, PC mount 2

DUT-HS HS39 Heatsink, Power DIP, slotted, 1.7°C/W 1

CSR-HS CR101-75AE Heatsink, 3 x TO-220, clip-on 1

CLA-TO-21E Heatsink Cam Clips 3

DUT-TW TW22 Thermal Washer, KR package 1

94639A288 3/16" nylon spacer 6

91841A007 #6-32 nut 6

90272A151 #6-32 x 3/4" panhead screw 2

90272A150 #6-32 x 5/8" panhead screw 4

91735A190 #8-32 x 1/4" panhead screw 4

2221 #8-32 x 2" standoff 4

TFT20014NA005-6" Teflon Tubing 1

EK76

4 EK76U Rev A

Optional Components (Not

Included)

P6-14 CON-SMA-EDGE-S SMA Connector 9

U2 LM6134BIN/NOPB Quad Op Amp, 14 DIP through hole 1

C1, 2, 3 - CAP 0805 Not Populated 3

C4 C0805C104M5RACTU CAP 0805 100nF 50V X7R 1

R9, 12, 13, 16, 17, 20 ERA-6AEB4992V RES 0805 49.9kΩ 1/8W 0.1% 6

R10, 11, 14, 15, 18, 19 ERA-6AEB103V RES 0805 10kΩ 1/8W 0.1% 6

R21 RMCF0805JT39K0 RES 0805 39kΩ 1/8W 5% 1

R22 3386P-1-103LF Trimmer, 10kΩ, Through hole 1

R23, 24, 25 RMCF0805ZT0R00 RES 0805 0Ω Jumper 3

EK76

EK76U Rev A 5

BEFORE YOU GET STARTED

• All Apex Microtechnology amplifiers should be handled using proper ESD precautions.

• Always use the heat sink included in this kit.

• Always use adequate power supply bypassing.

• Do not change the connections while the circuit is powered.

• Initially set all power supplies to the minimum operations levels allowed in the device data sheet.

• Check for oscillations.

• Please refer to Application Note, AN01 for general operating conditions.

ASSEMBLY INSTRUCTIONS

During the assembly, please refer to the circuit schematics, assembly drawings, and the data sheet of the

part being used on the evaluation kit.

1. Note that each side of the EVAL94 circuit board is identified as either the Component side or the DUT

(Device Under Test) side. The component side has the designators printed on that side.

2. First, insert the 16 pin receptacles from the DUT side, into the DUT position. These will be a tight fit, so a

flat piece of metal is recommended as a finger-shield to fully engage the receptacles with the plated

through-holes. This tight fit is meant to keep perpendicularity between the PCB and the pin direction.

Ensure the hexagonal portions go completely through the holes, and the circular flange rests on the DUT

side of the PCB. Solder the pin receptacles from the Component side.

3. Solder the surface-mount capacitors CBP1, CBP2, and CBP3 on the Component side.

4. If current-sense offset or gain adjustment is required, install the optional components U2 and surrounding

resistors/capacitors. These components are not included, as this is only necessary in unique applications

where current sense must be tightly managed. See "Current Sense" section below.

5. Install the smaller components, including R4-8, D1-6, LED1, and P2. Note that R6 includes a socket to eas-

ily swap between high-impedance inputs (R6 not installed) and 50-Ohm terminated inputs (R6 installed).

Each element of this resistor can dissipate up to 200mW. Match the direction of R6 with the PCB designa-

tor when installing. Also match all diode orientations with their respective designators.

6. Use a piece of heavy wire (16 to 14 AWG, 1.3 to 1.8 mm) to short J1. This should be the only connection

between digital ground (DGND) and power ground (PGND).

7. Install P3, P4, and P5 BNC connectors for output sense with an oscilloscope. This is best done by soldering

the center pin first to anchor the component in place, then soldering the 4 external lugs.

8. Install R1, R2, and R3. Their heights must be set by the widened portion of the pins resting on the Compo-

nent side of the PCB. This will place the plastic package 4mm above the PCB.

9. Apply a thin layer of thermal grease (not included) the backside of R1, R2, and R3. Place the CSR-HS

(CR101-75AE; the smaller of the two included heatsinks) behind these resistors, with the mounting lugs

engaging the PCB holes. Solder these mounting lugs while keeping the heatsink perpendicular to the

board.

10. From either side, slide the cam clips (CLA-TO-21E) into the hooked slot of the CSR-HS. The tabs should be

pointed at a 45° angle down and away from the heatsink. Once the clip is in front of a resistor, flip the tab

all the way up to apply pressure to each resistor.

11. Install P1, P15, and P16.

12. Install electrolytic bypass capacitors CBP4 and CBP5, ensuring that the orientation matches the circuit

schematic drawing.

13. P6 through P14 have edge-connector pads. These pads are designed for edge-mount SMA connectors (not

included). If SMA connection is not desired, leave these pads unpopulated. Otherwise, use recommended

part number CON-SMA-EDGE-S (or similar) and solder these to the board.

EK76

6 EK76U Rev A

14. Make sure all leads protruding out the DUT side are clipped to under 1/8 inch (3mm).

15. When installing the DUT-HS, start by temporarily fastening the central 2 holes to the board. Pass the #6-

32 x ¾" screws through the heatsink and place a nylon spacer on each. Carefully pass this assembly

through the matching holes on the PCB and fasten with #6-32 nuts on the component side.

16. Now, make a similar assembly at each corner of the heatsink. Pass the #6-32 x 5/8" screws through the

heatsink while holding a nylon spacer between the board and heatsink (pliers would be helpful). Fasten

with #6-32 nuts on the component side and tighten.

17. Undo the first two screws and nuts, but leave the nylon spacers sandwiched between the heatsink and

board.

18. Cut the Teflon tubing into ¼ inch (6mm) pieces and slide the pieces onto the pins of the DUT. This is an

added precaution to prevent the heatsink or thermal washer from shorting against the pins. One sleeve

on each of 4 corners of the DUT is sufficient. Do not cut Teflon longer than the recommended length, as

this will prevent proper seating of the DUT on the heatsink.

19. Place a single TW22 thermal washer over the heatsink area where the DUT will go. Place the DUT in this

space, so its pins pass through the TW22 and the heatsink slots. Rest the pins over the pin receptacles

from step 2. Engaging all 16 receptacles requires much force. Rather than applying this force by hand,

reinstall the #6-32 x ¾" screws and nuts, this time passing through the DUT tabs and TW22. With the #6-

32 nut on the component side, tighten the screws in small increments, switching frequently between the

two screws. Make sure the TW22 is loose and centered up until the final tightening, or else the metallic

foil can short out the DUT's pins.

20. Use the #8-32 x ¼" screws to mount a 2-inch standoff on each corner of the PCB.

HEATSINK GUIDELINES

Determining heatsink size for SA310 depends on several factors. Refer to SA310 datasheet for more infor-

mation on calculating power dissipation, thermal resistance, and finding thermal ratings.

MOTOR CONTROL

P2 is designed to match the “remote amplifier” connector on Precision Motion Device's DK78113 devel-

oper kit for the Juno Velocity & Torque Control IC. Follow the instructions in the DK78113 User Manual to

connect a remote amplifier. Applications requiring torque control will require the Current Sense gain and off-

set circuit described below. Use default values when pairing with the Juno device.

Other motor control ICs may be used with EK76, but these may require different wiring and/or current

sense circuits.

EK76

EK76U Rev A 7

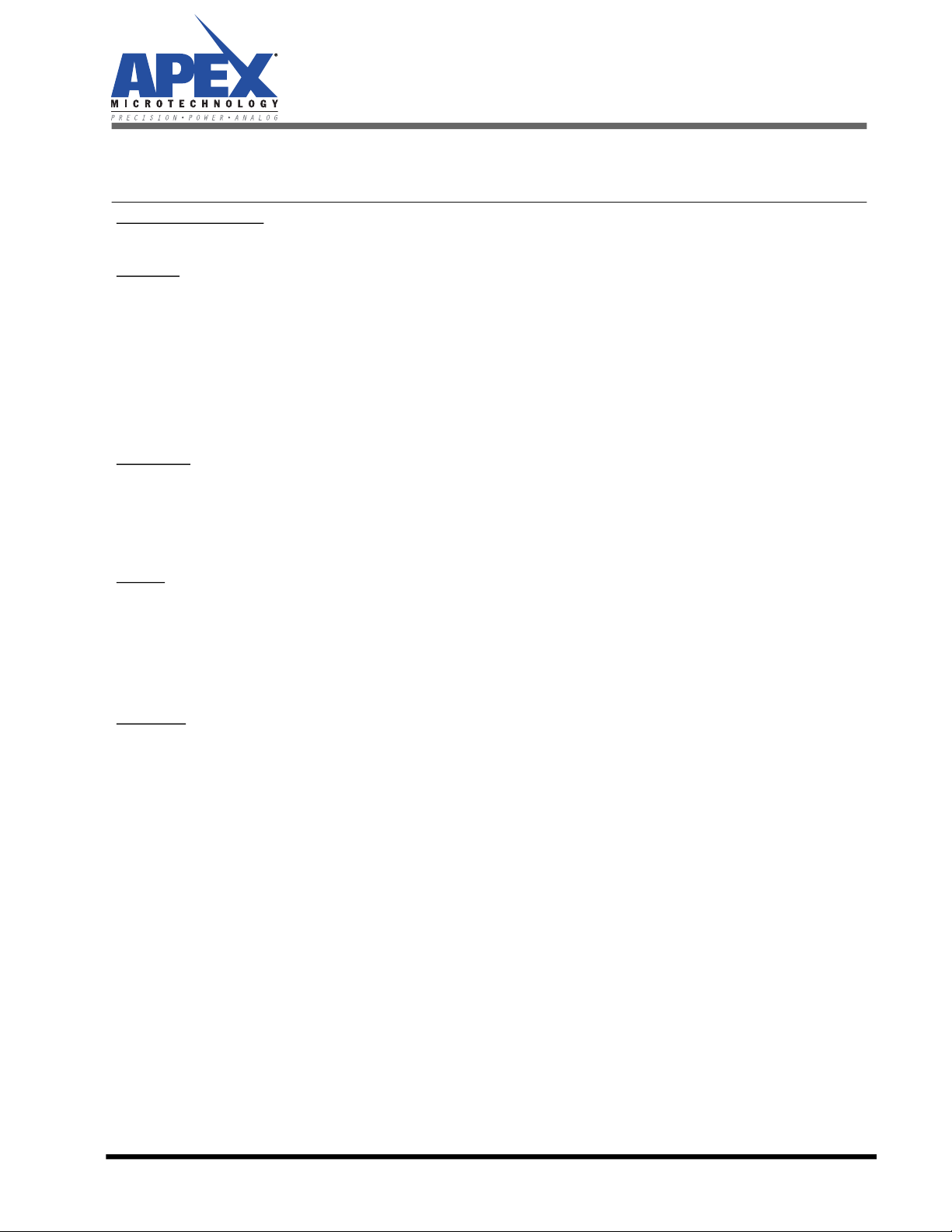

CURRENT SENSE

The optional current sense gain and offset circuit is designed to interface with various ADCs in closed-

loop current/torque control. Follow the below schematic and equations to determine the proper component

values.

After assembly of the EK76 including the above Current Sense circuit, R22 must be trimmed to reach the

desired value of VOS. To do this, attach a Voltmeter to measure the voltage between pins 11 (negative) and

13 (positive) of P2. Apply the low-voltage supply VCC (+VS should NOT be active). Adjust R22 until the desired

value for VOS is shown on the Voltmeter.

The following equation represents the Low-Side Phase Current (IPHASE) as a function of voltage measured

at IM_X (VM):

Value Applicable Designators on

EVAL94 Equation Default

Value Units Suggested

Tolerance

VOS Bias ADC min input (or higher) 1.65 V -

VOUT_MAX - ADC max input (or lower) 3.3 V -

IOUT_MAX - < 80 A 33 A -

Gain -(VOUT_MAX-VOS) / (IOUT_MAX *

10 mΩ) 5 V/V -

RF R9, 12, 13, 16, 17, 20 1.8k < RF < 100k 50k Ω 0.1%

RIN R10, 11, 14, 15, 18, 19 RF / Gain 10k Ω 0.1%

RT R22 (potentiometer) 1k < RT < 100k 10k Ω -

RL R21 Roughly RT ((VCC/2VOS) – 1) 39k Ω -

C4 C4 C4 = 100n 100n F X7R

fFIL - Typically 200k < fFIL < 1M ∞Hz -

RFIL R23, 24, 25 Typically 100 < RFIL < 1k 0 Ω -

CFIL C1, 2, 3 1 / (2π * fFIL * RFIL) 0 F -

R1-3

10

ŵɏ

R

IN

R

IN

+

-

R

F

R

F

BIAS

R

FIL

C

FIL

IM_X

PGND_X

3X

+

-

1X

BIAS

R

L

R

T

V

CC

C4

PGND DGND

DGND

Phase

Current

IPHASE VMVOS

–

Gain 0.01

---------------------------------=

EK76

8 EK76U Rev A

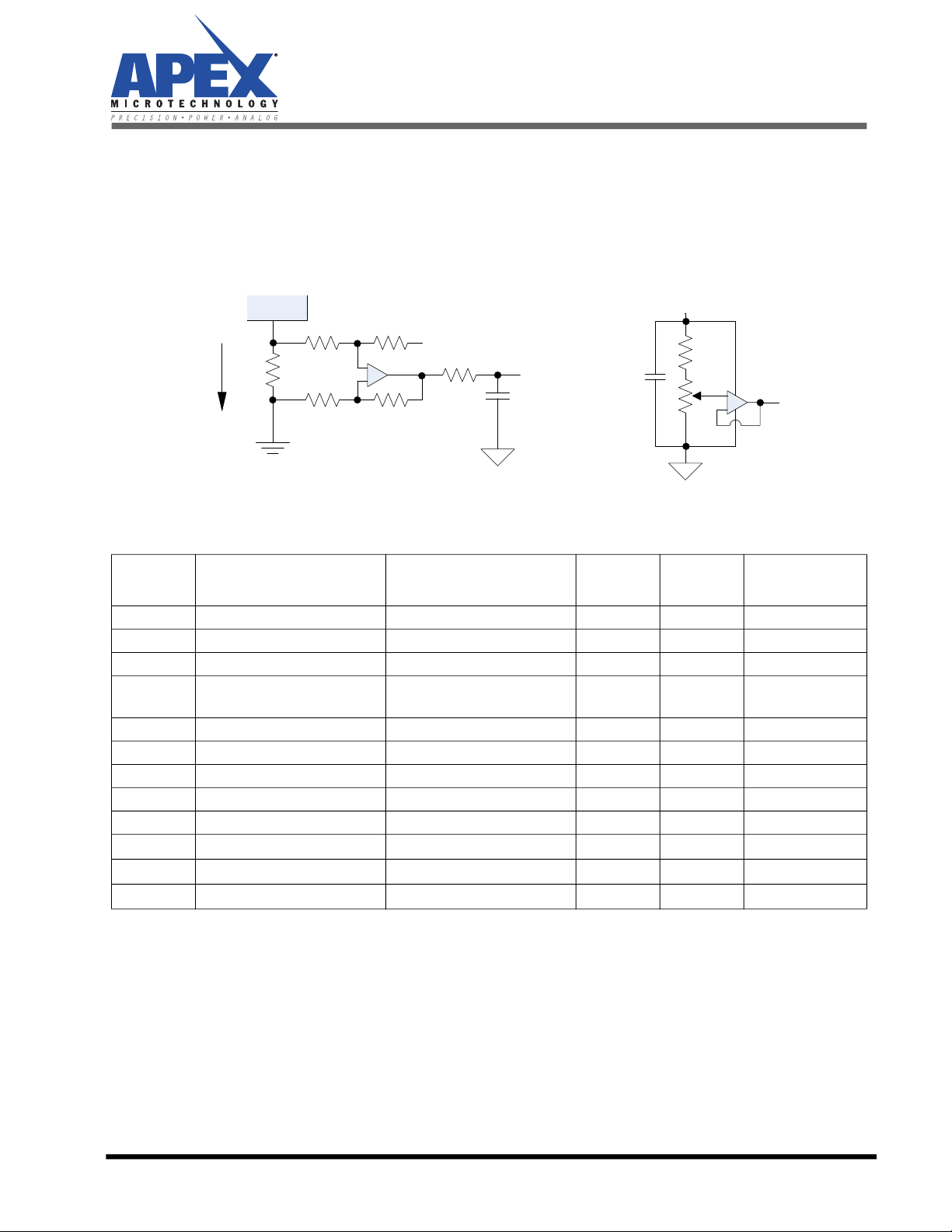

Figure 2: Top View

EK76

EK76U Rev A 9

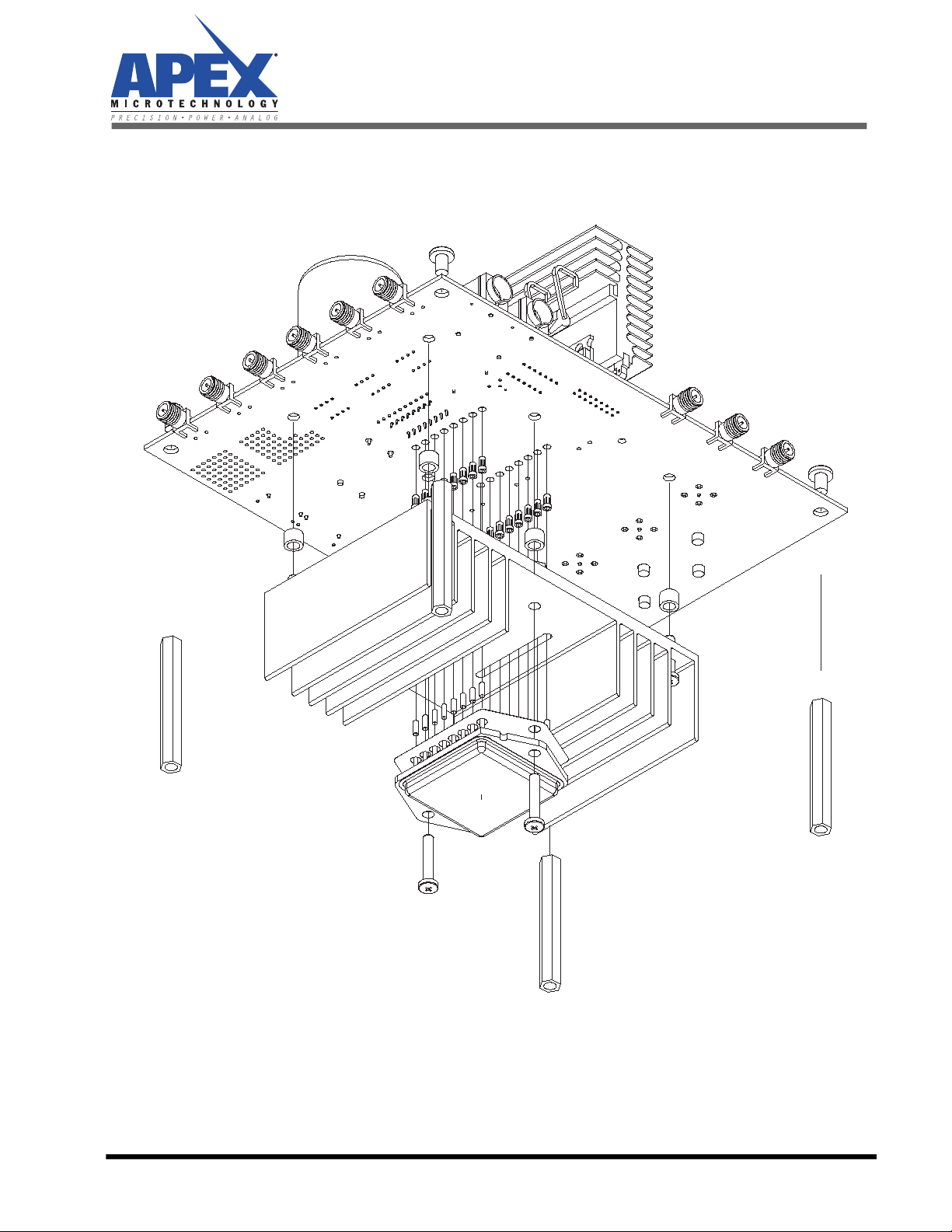

Figure 3: Bottom View

EK76

10 EK76U Rev A

NEED TECHNICAL HELP? CONTACT APEX SUPPORT!

For all Apex Microtechnology product questions and inquiries, call toll free 800-546-2739 in North America. For

inquiries via email, please contact apex.s[email protected]. International customers can also request

support by contacting their local Apex Microtechnology Sales Representative. To find the one nearest to you,

go to www.apexanalog.com

IMPORTANT NOTICE

Apex Microtechnology, Inc. has made every effort to insure the accuracy of the content contained in this document. However, the information is

subject to change without notice and is provided "AS IS" without warranty of any kind (expressed or implied). Apex Microtechnology reserves the right

to make changes without further notice to any specifications or products mentioned herein to improve reliability. This document is the property of

Apex Microtechnology and by furnishing this information, Apex Microtechnology grants no license, expressed or implied under any patents, mask

work rights, copyrights, trademarks, trade secrets or other intellectual property rights. Apex Microtechnology owns the copyrights associated with the

information contained herein and gives consent for copies to be made of the information only for use within your organization with respect to Apex

Microtechnology integrated circuits or other products of Apex Microtechnology. This consent does not extend to other copying such as copying for

general distribution, advertising or promotional purposes, or for creating any work for resale.

APEX MICROTECHNOLOGY PRODUCTS ARE NOT DESIGNED, AUTHORIZED OR WARRANTED TO BE SUITABLE FOR USE IN PRODUCTS USED FOR LIFE

SUPPORT, AUTOMOTIVE SAFETY, SECURITY DEVICES, OR OTHER CRITICAL APPLICATIONS. PRODUCTS IN SUCH APPLICATIONS ARE UNDERSTOOD TO BE

FULLY AT THE CUSTOMER OR THE CUSTOMER’S RISK.

Apex Microtechnology, Apex and Apex Precision Power are trademarks of Apex Microtechnology, Inc. All other corporate names noted herein may be

trademarks of their respective holders.

TEST ASSEMBLY

EQUIPMENT NEEDED

1. Power Supplies

2. Digital Controller or 6+ Channel Pattern Generator

3. Oscilloscope

4. Proper Heatsinking System

TEST SETUP

Make sure all supplies are turned off before connection. Connect the power supplies VCC (via P15 and

P16) and +VS (via P1). See SA310 datasheet for acceptable voltage levels. The +VS LED will be visibly bright for

voltages 30V and above. For lower voltages, consider using a smaller-value resistor for R8.

When sequencing power supplies, use the following order:

Power ON: VCC, then +VS

Power OFF: +VS, then VCC

It is recommended to first test the device with no load attached. Ensure the output waveform follows the

expected results before connecting a load. Consider power dissipation in the amplifier, sense resistors, and

the load.

The BNC connectors P3, P4, and P5 are designed for coaxial measurement of the output; these are not

meant to carry significant current. ONLY USE P1 FOR HIGH-CURRENT CONNECTIONS. To use P3-P5, for volt-

ages within the oscilloscope's input rating, BNC cables may be used to connect directly to the oscilloscope.

For higher voltages, use a high-voltage oscilloscope probe with a probe-tip-to-BNC adapter. Alternatively, use

high-voltage BNC attenuators in series with the BNC cable.

Table of contents

Other Apex Digital Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Milnor

Milnor MWF125J7 manual

Sunnen

Sunnen SV-2460 Installation, setup and operation instructions

MultiBlast

MultiBlast PRO operating manual

Rohm

Rohm FORTO-H 70 Translation of the original operating manual

Excelitas Technologies

Excelitas Technologies OmniCure AC7 Series user guide

X-FLOC

X-FLOC Minifant M99 operating manual

Alemite

Alemite 8587-1 Service guide

CommScope

CommScope OMX Bay System Application guide

Sumitomo

Sumitomo Cyclo BBB4 Operation and maintenance manual

Pepperl+Fuchs

Pepperl+Fuchs BEBCO EPS 1002 Installation & operation manual

G.B.C

G.B.C HYPERMAXI 20 instruction manual

Siemens

Siemens 3VA1 100 630A Series operating instructions