Miki Pulley 121 Series User manual

MIKI PULLEY/TRS-CBUN-E-001H-00/MD-000103254 121/122/125/126

ELECTROMAGNETIC CLUTCH & BRAKE

ELECTROMAGNETIC CLUTCH AND BRAKE UNITS

121/122/125/126

Instruction Manual

☆This instruction manual describes mainly installation, removal, and notes pertaining to same for

standard-specification products after purchase; see the Miki Pulley website and our latest catalog for product

specifications and performance.

☆Before use this product, read the instruction manual carefully and use the product safely and correctly.

☆First, please check that it is the correct product and if the product was damaged during transportation.

CONTENTS

1.

STRUCTURE AND PARTS

4.

CONNECTION

2.

NOTES

5.

OPERATION CHECK

3.

MOUNTING

6.

MAINTENANCE & INSPECTION

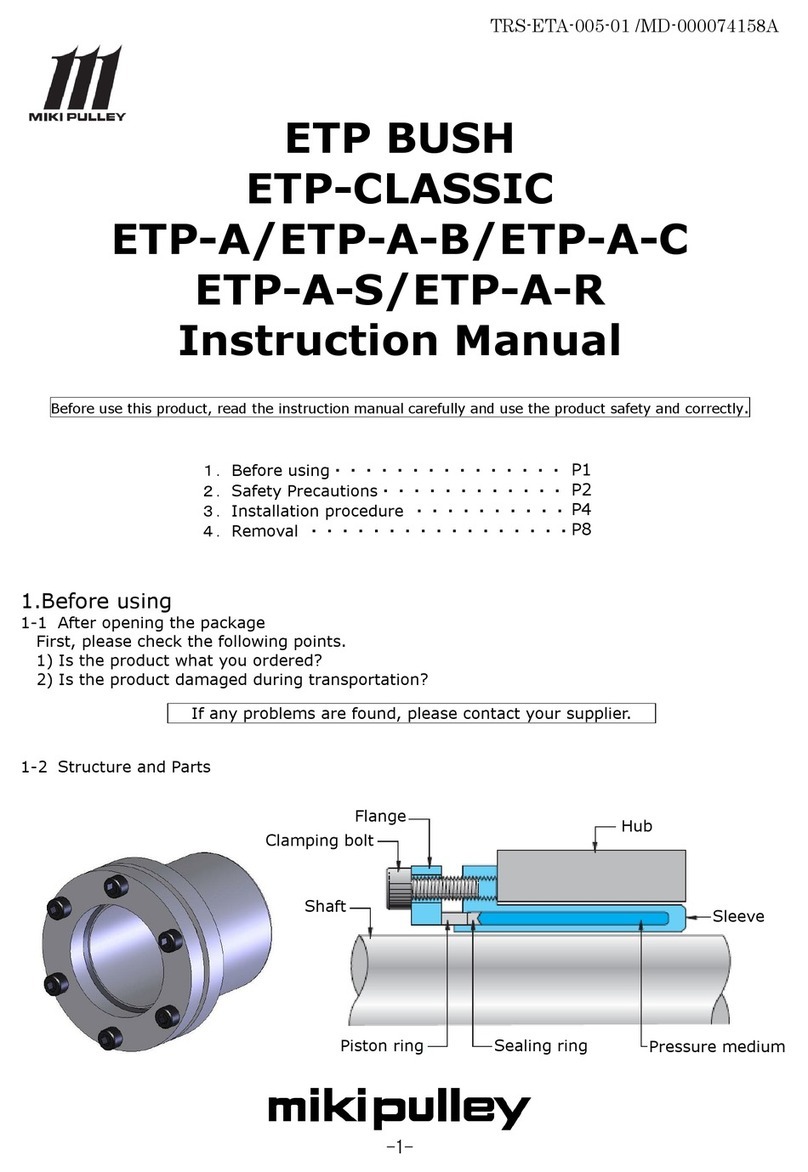

1.STRUCTURE AND PARTS

Note The device (application) and structure depend on the product model and type.

Note The base can be either steel plate or cast, depending on the product model and size.

■125

[1]Housing [2]Rotor [3]Clutch armature [4]Clutch stator

[5]Brake armature [6]Brake stator [7]Base [8]Terminal block

※Description of model names is given for Model 125

-1-

MIKI PULLEY/TRS-CBUN-E-001H-00/MD-000103254 121/122/125/126

2.NOTES

2.1 SAFETY PRECAUTIONS

Please read carefully through the instruction manual and the technical information for proper use and safety.

In this manual, safety precautions are classified by "DANGER" and "CAUTION".

【CLASS】

DANGER When death or serious injury may result by mishandling.

CAUTION When disability or only physical damage may result by mishandling.

【FIGURE SIGN】

PROHIBITION In the handling of the product, it indicates that prohibit the act.

CAUTION In the handling of the product, it indicates that attention is required.

MANDATORY In the handling of the product, it indicates that the action is compulsory on the

basis of the instructions.

DANGER

Make sure that the main power of the

product is off before mounting or

performing maintenance/inspection.

Set up a safety mechanism such as a

safety brake to avoid any danger.

It is extremely dangerous if the driving part

starts operating by accident while handling

the product.

The driven and driving sides could become

completely detached if the product is

damaged while in operation and not

immediately halted.

Do not use in flammable environments.

Be sure to use a safety cover.

There is a danger of explosion due to

sparks from machinery or the product in

operation. In particular, explosion can

occur easily in environments with

oil/grease or flammable gas.

It is extremely dangerous if hands, fingers,

hair, clothing, etc. get caught in the

product or a rotating part while in

operation.

CAUTION

Do not touch the hot clutch and brake

body or power supply.

Always use bolts specified by Miki

Pulley and a calibrated torque wrench

correctly to install brakes at the

specified tightening torque.

Hot while in operation; will result in burn

injuries if touched. Warm surroundings

will prevent clutch and brake body heat

from dissipating; locate in a

well-ventilated area.

Depending on the tightening adjustment

of bolts or screws, exceptionally

dangerous situations such as product

damage or performance degradation

could occur.

Be careful lifting a heavy weight.

Do not lift with a bad posture.

Use a safety glasses or gloves.

Straining yourself to lift a heavy product or

using a torque wrench, or an awkward

posture when installing the product in a

machine could cause back injury.

Sharp portions of product bore diameter,

keyway, shaft keyway, etc. may cause

injury. Wear protective equipment to also

prevent burn injuries and electric shock.

-2-

MIKI PULLEY/TRS-CBUN-E-001H-00/MD-000103254 121/122/125/126

2.2 IMPORTANT POINTS OF PRODUCT SPECIFICATIONS

Do not use the product in a bad

environment.

Product is for dry use; do not allow

exposure to water or oil/grease.

Request disposal with a

waste-collection company, or dispose

of according to laws and regulations.

Operating temperature range

:

-10~+40℃

Do not use the product in an environment

where water, oil, or chemicals may spill

(no matter how little), that is corrosive,

where temperature is extremely high or

low, that is dusty, where condensation

forms, that is exposed to wind and rain, or

that is subject to a high degree of

vibration/impact; may cause product

damage or performance deterioration.

When disposing of the product, request

disposal with professionals, or dispose of

according to law and local regulations if

disposing of product by yourself.

Do not dispose of or leave unattended

where children play or in a public space.

Comes as a finished product.

Do not unnecessarily disassemble,

modify, or additionally process the

product.

We do not guarantee quality nor shall we

be liable for damages in the event of

damage or affected performance of the

product or of injury or accident occurring

as a result of the product being

disassembled, modified, or additionally

processed by the customer.

2.3 IMPORTANT POINTS BEFORE MOUNTING

Do not carry with the lead wire

dangling.

Do not pull or bend the lead wire

forcefully.

Make sure to keep fluctuations in

power supply voltage to within ± 10 %

of the rated voltage.

May break wire, and render the product

unusable. If lead wire breaks or slips from

your hand, the product may fall on and

injure your foot.

Extreme fluctuations in power voltage

may prevent the product from reaching

optimal performance.

Do not use any bolt or screw other than

the bolts on the product.

Implement screw-locking measures

such as an adhesive thread-locking

compound to bolts and screws used to

install the product.

Check the strength category of the bolt or

screw as well as the strength and material

of where the product is being installed.

Inadequate strength will result in the

product being poorly installed and may

cause an accident.

Loosening of the bolts or screws due to

operational vibration, etc. may allow the

product to detach and cause an accident.

Do not bang with a hammer or other

tool when inserting a pulley or

sprocket onto the shaft or armature

hub.

Bore tolerance of the pulley or

sprocket being inserted onto the shaft

or armature hub should be finished to

H7 class.

Use the supplied insertion set.

Forcefully inserting the pulley or sprocket

may damage and affect the performance

of the product.

-3-

MIKI PULLEY/TRS-CBUN-E-001H-00/MD-000103254 121/122/125/126

3.MOUNTING

(1)

Securely fasten base on sturdy and flat surface with bolts and washers. Installation in any direction is possible.

See chart for dimensions of holes for installing base. Select the bolt length according to your design specifications.

Note

The infiltration of foreign matter into the frictional surface is undesirable. Infiltration of oils markedly degrades

frictional force. Dust, especially if it contains metal particles, can cause problems by damaging the frictional surface

and rotating parts.

Chemical infiltration can cause corrosion, in addition to the rust described above.

In such environments, consider the use of a protective cover.

(2)

When installing a pulley, sprocket, etc. on the shaft or armature hub, be sure to use screw holes at end of shaft and

on end face of armature hub and the supplied insertion set.

Do not bang on with a hammer, etc.

Note

Hexagon socket head cap screws may be supplied in place of headless bolts and hexagon nuts in the insertion set.

Note

Pulleys and sprockets require processing for holes, keyways, etc. A bore tolerance of H7 class is recommended.

-4-

MIKI PULLEY/TRS-CBUN-E-001H-00/MD-000103254 121/122/125/126

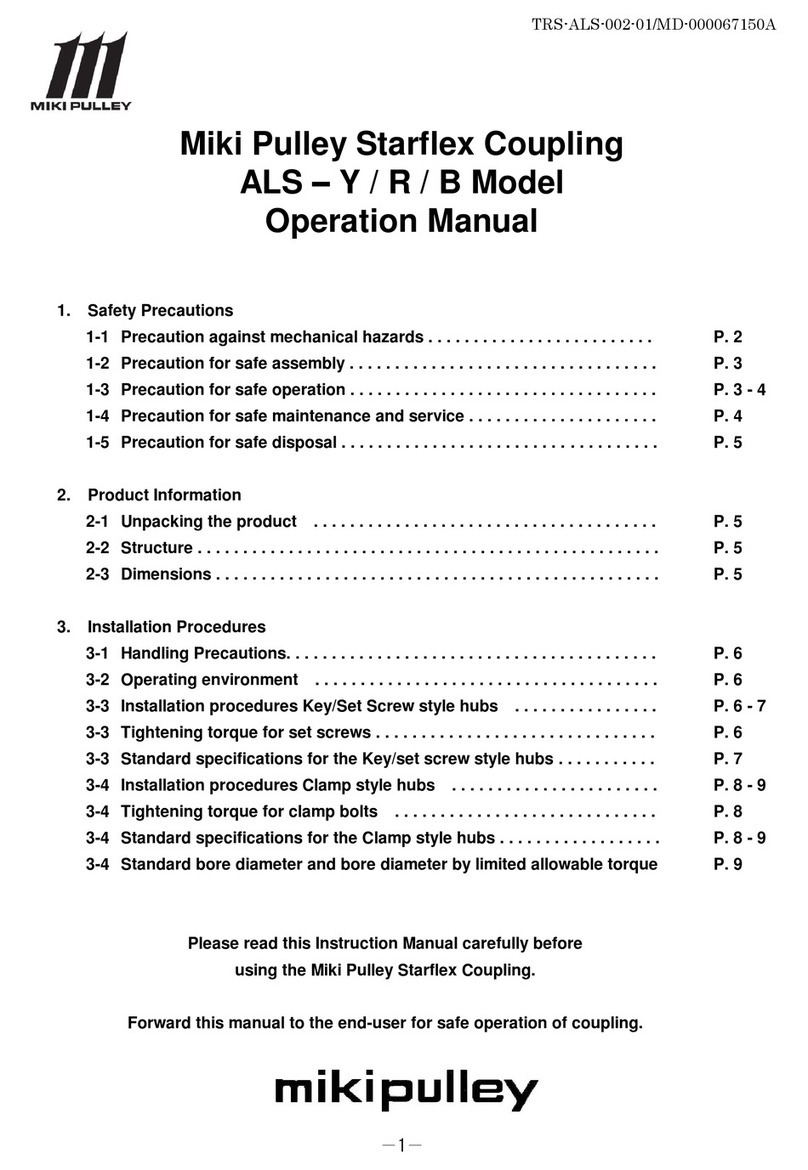

【Dimensions for screw holes at end of shaft and on end face of armature hub】

※Screw holes at end of shaft not provided with 125-05-12G.

(3)

Install the CB unit to the machine so that the travel lines are correct, and to align the centers of both shafts correctly.

The table below shows the allowable values for radial load that can be applied to the shaft of the unit.

-5-

This manual suits for next models

5

Other Miki Pulley Industrial Equipment manuals