User Instructions must always be available to the user and are not to be removed except by the user of this equipment. For proper use, see supervisor,

User Instructions, or contact the manufacturer. Werner Co. can supply additional information upon request.

Compliant fall arrest and emergency rescue systems help prevent serious injury during fall arrest. Users and purchasers of this equipment must read

and understand the User Instructions provided for correct use and care of this product. All users of this equipment must understand the instructions,

operation, limitations and consequences of improper use of this equipment and be properly trained prior to use in accordance with applicable

standards. All references to “applicable standards” refer to EN, ANSI, OSHA, state, local, and/or federal standards that apply to approved use. The local

competent person must keep these instructions, make them available to users, and require their use.

Misuse or failure to follow warnings and instructions may result in serious personal injury or death.

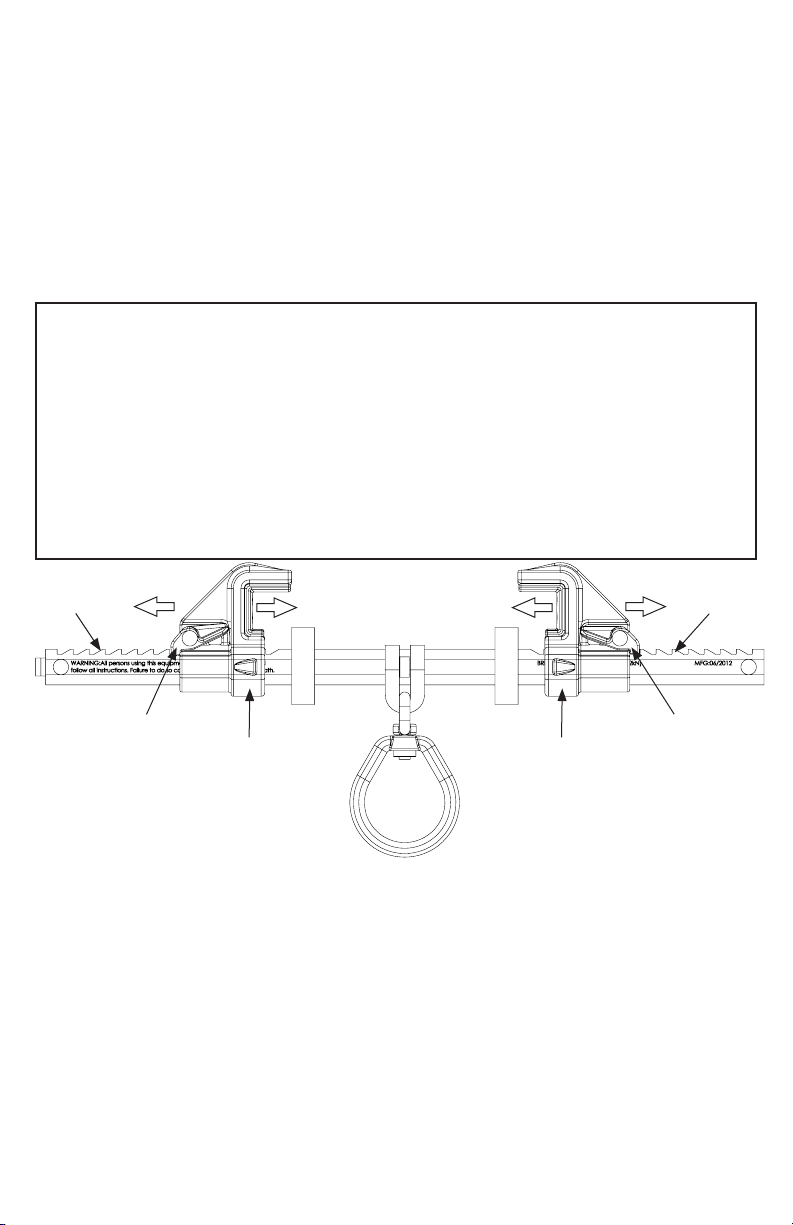

PURPOSE

The A555000 is an anchorage connector designed to function as an interface between the anchorage and a fall arrest, work

positioning, rope access, or rescue system for the purpose of coupling the system to the anchorage. Any references to“anchorage

connector” in this manual include, and apply to, the A555000.

USE INSTRUCTIONS

1. A user must be of sound mind and body to properly and safely use this equipment in normal and emergency situations.

2. Before using a personal fall arrest system, user must be trained in accordance with the requirements of applicable standards

in the safe use of the system and its components.

3. Only use with systems that comply with applicable standards. The anchorage must have the strength capable of supporting

a static load, applied in the directions permitted by the system, of at least 5,000-lbf (22kN) in the absence of certication.

4. The user shall be equipped with a means of limiting the maximum dynamic forces exerted on the user during the arrest of a

fall to a maximum of 8 kN (1800-lbf). In the EU these forces must be limited to 6kN (1350-lbf).

5. Use of this product must be approved by an engineer or other qualied person (as dened by OSHA 29 CFR 1926.32 (m) and

EN 795:2012 Annex 1) to be compatible with any and all structural & operational characteristics of the selected installation

location and system to be connected to this anchorage connector.

6. The anchorage connector must be inspected prior to each use for wear, damage, and other deterioration. If defective

components are found the anchorage connector must be immediately removed from service in accordance with applicable

standards and the manufacturer’s inspection requirements.

7. The anchorage connector should be positioned in such a way that minimizes the potential for falls and the potential fall

distance during use. The complete fall arrest system must be planned (including all components, calculating fall clearance,

and swing fall) before using.

8. A rescue plan, and the means at hand to implement it, must be in place that provides the prompt rescue of users in the

event of a fall, or assures that users are able to rescue themselves.

9. After a fall occurs the anchorage connector must be removed from service and destroyed immediately.

10. The applicable essential health and safety requirements from EU Regulations have been checked and tests carried out to

verify the conformity of this PPE are available upon request.

11. Digital copy of this instructions can be found at at: https://www.wernerco.com/us/products/fall-protection/anchorage-

connectors/A5500Series/A555000.

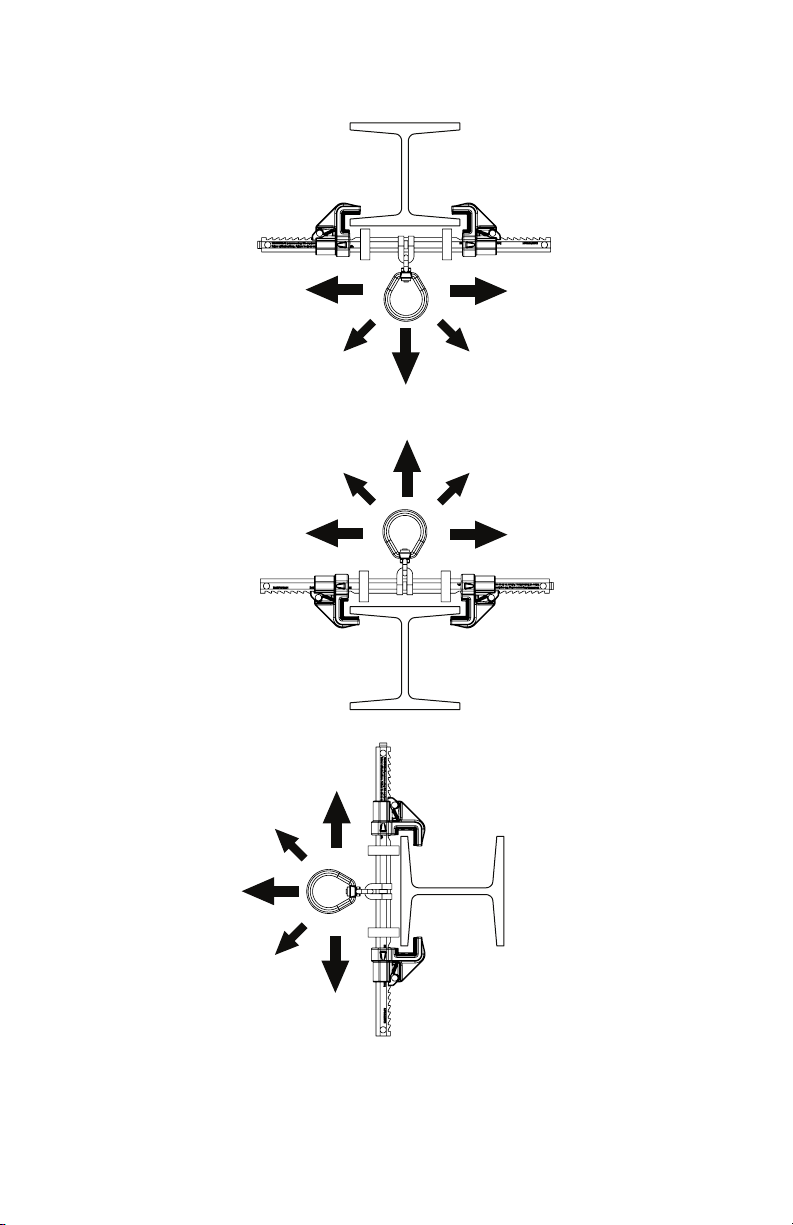

USE LIMITATIONS: This anchorage connector has been tested in compliance with the requirements of ANSI/ASSE Z359.7 and

EN 795:2012 Type B. Compliance testing covers only the hardware and does not extend to the anchorage and substrate to which

the anchorage connector is attached. The anchorage connector must not be used outside its limitations, or for any purpose other

than that for which it is intended. If this anchorage connector is used dierently from these instructions, it must be designed,

installed, and used under the supervision of an engineer according to ANSI Z359.6 and local building codes as applicable.

1. The anchorage connector is designed for single user.

2. The anchorage connector may only be loaded as shown in the LOADING CONDITIONS DIAGRAM.

3. The anchorage connector is designed to be used in temperatures ranging from -40ºF to +130ºF (-40°C to +54°C).

4. Do not expose the anchorage connector to chemicals or harsh solutions which may have a harmful eect.

5. Do not alter or modify this product in anyway.

6. Caution must be taken when using any component of a fall arrest, work positioning, rope access, or rescue system near

moving machinery, electrical hazards, sharp edges, or abrasive surfaces, as contact may cause equipment failure, personal

injury, or death.

7. Do not use/install equipment without proper training by a“competent person”as defined by OSHA 29 CFR 1926.32(f) and

EN795:2012 Annex A1.

8. Do not remove the labeling from this product.

9. Additional requirements and limitations may apply depending on anchorage type and fastening option utilized for

installation. All placements must be approved by an engineer or other qualied person.

10. This anchorage connector should not be used as part of a horizontal lifeline system that has not been designed and/or

approved to be used with 5,000-lbf (22kN) anchorage connectors.

11. The anchorage connector should only be used as intended (see PURPOSE).

12. If attaching the anchorage connector to the support structure by methods other than instructed, the attachment must be

certied by a qualied person to meet the requirements of the system that will connect to the anchorage connector.

Read This Instruction Manual Carefully Before Using This Equipment.