X-Floc GmbH

Rosine-Starz-Straße 12

71272 Renningen · Germany

Engineering office

Special machines

Construction

Tel.: +49-(0)7159

80470-30

Fax: +49-(0)7159 – 80470-40

http://www.x-floc.com

M99 minifant operating instructions

Version M99E from 20.02.2014

Page 2 of 35

Contents

1Basic Safety Information ..........................4

1.1Responsibility of the contractor .................4

1.2Responsibility of personnel........................5

1.3Dangers associated with machine

operation....................................................5

1.4Intended use..............................................5

1.5Warranty and liability.................................5

2Safety regulations -basic information.....6

2.1General......................................................6

2.2Symbol and instruction descriptions..........6

2.3Organisational measures...........................6

2.4Protective Equipment ................................6

2.5Guidelines..................................................6

2.6Training of staff..........................................6

2.7Machine control .........................................7

2.8Safety measures with normal use .............7

2.9Electric shock hazards...............................7

2.10Danger zones ............................................7

2.11Maintenance and trouble shooting............7

2.12Structural alterations to the machine.........7

2.13Cleaning the machine and waste

disposal......................................................7

2.14Operating noise.........................................7

2.15Copyright ...................................................7

2.16Taking delivery of the machine..................8

2.17Registration................................................8

2.18General......................................................8

2.18.1Installation site....................................8

2.19Machine field of application.......................8

2.19.1Foreign objects...................................8

2.20Electrical connection..................................8

2.20.1Earthing ..............................................8

2.21Airlock ventilation.......................................8

3Directions for Use....................................10

3.1Machine depiction....................................10

3.2Setting up the Machine............................12

3.2.1Handling the Machine.......................12

3.2.2Moving and positioning the machine.12

3.3Connecting the Machine..........................12

3.3.1Electrical connection.........................12

3.3.2Hose connection...............................13

3.4Working with the machine. ......................13

3.5Switching on the machine........................13

3.5.1Warm-up...........................................13

3.5.2Manual operation..............................13

3.5.3Radio remote control operation........13

3.5.4Cable remote control (optional)........14

3.5.5Material volume control ....................14

3.5.6Air flow volume control .....................15

3.5.7Button operation for maintenance

tasks. ................................................15

3.6Machine settings......................................15

3.6.1General information..........................15

3.7Examples.................................................15

3.7.1Pitched roof ......................................15

3.7.2Open blowing church dome..............16

3.7.3Dry injection of cotton insulation in to

a wall.................................................16

4Maintenance.............................................17

4.1Summary .................................................17

4.2Maintenance work in detail......................18

4.2.1Drive motor and gears......................18

4.2.2DS and DS-pro models special features

18

4.2.3Air feed unit...................................... 18

4.2.4Airlock............................................... 18

4.2.5Agitation unit. ................................... 18

4.2.6Machine electrical equipment .......... 18

5Electrical circuit diagram. ...................... 19

5.1M99-230V-3.6kW standard model circuit

diagram ................................................... 19

5.2M99-230V-3.6kW-DS circuit diagram ..... 20

5.3M99-230V-3.6kW-DS-pro circuit diagram20

5.4Frequency converter-parameter set for DS

and DS-pro models................................. 22

6Troubleshooting...................................... 23

6.1Trouble shooting ..................................... 23

6.2FAQs (frequently asked questions)......... 23

7Technical data / radio remote control

operating instructions............................ 25

7.1Hand-held transmitter.............................. 25

7.1.1Operation ........................................... 1

7.1.2Buttons............................................. 25

7.1.3Power supply / battery...................... 26

7.1.4Use of rechargeable batteries.......... 26

7.2Hand-held receiver.................................. 26

7.2.1OperationFehler! Textmarke nicht

definiert.

7.2.2Positioning the receiver.................... 26

7.2.3Connector pin assignment ............... 26

8EC Declaration of Conformity................ 27

9M99 E assembly drawings...................... 28

10Technical dataM99 Minifant, 230V......... 33

11Index......................................................... 34

List of Illustrations

Illustration Illustration 1: Machine depiction

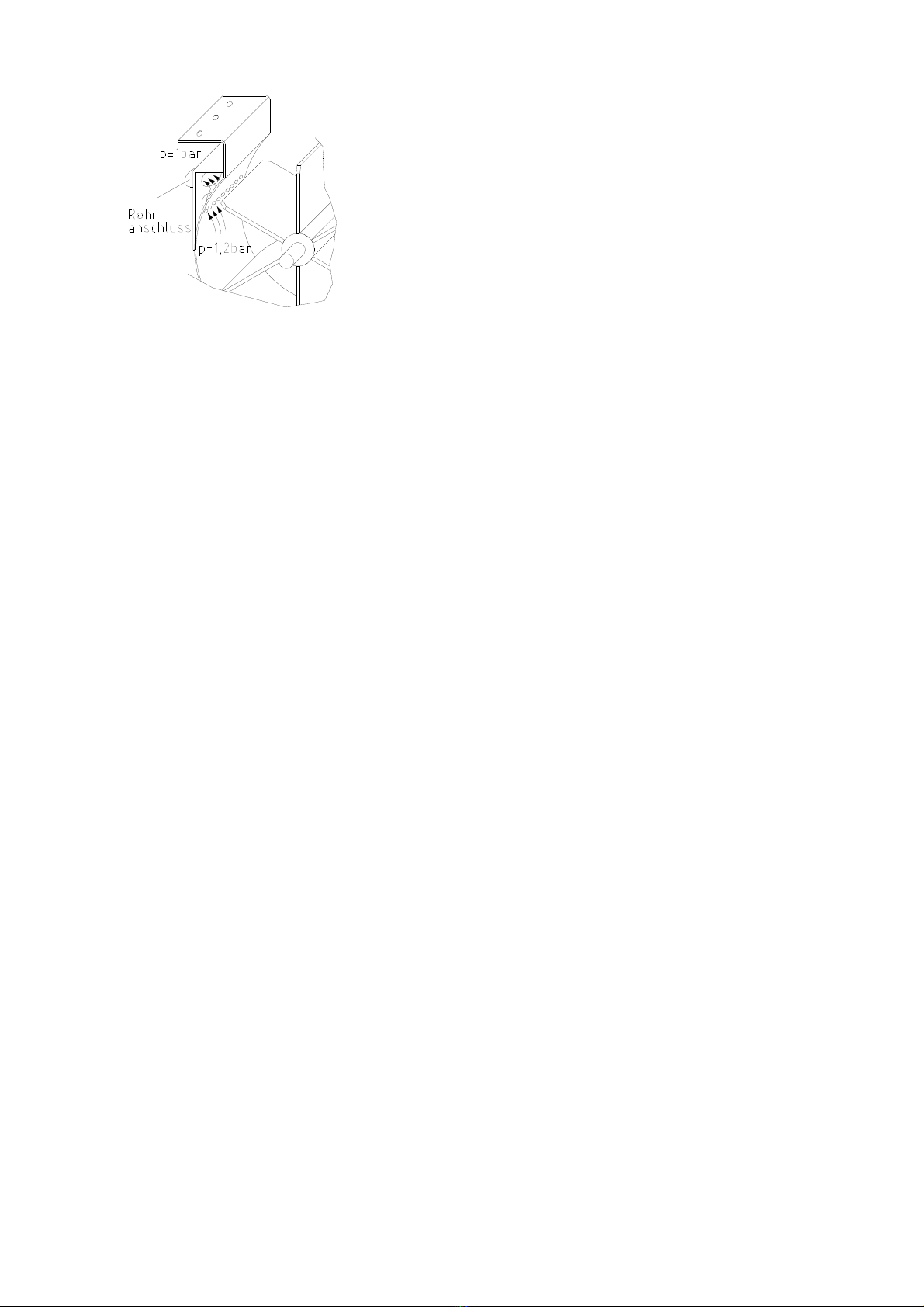

2: Airlock ventilation .............................................. 9

Illustration 3: Machine description 10

Illustration 4: Moving the machine....................... 12

Illustration 5: Hand-held transmitter and receiver:13

Illustration 6: FFB2000-Pro radio remote control

with hand-held transmitter and receiver.............. 14

Illustration 7: Cable remote control and control ca-

ble........................................................................ 14

Illustration 8: Feed gate adjustment.................... 14

Illustration 9: Hand-held transmitter and receiver

............................................................................ 14

Illustration 10: FFB2000-Pro radio remote control

with hand-held transmitter and receiver.............. 16

Illustration 11: Cable remote control and control

cable . ................................................................. 10

Illustration 12: Feed gate adjustment

............................................................................. 11

Illustration 13: Adjusting knob for airlock rotational

speed................................................................... 11

Illustration 14: M99 minifant adjustment

............................................................................. 12

Illustration 15: Standard model circuit diagram

............................................................................. 20

Illustration 16: DS model circuit diagram

............................................................................. 21