3. How to use the MANUAL

This manual is an official document prepared by Apollo Ltd, and must not be

amended or altered without the permission of the company. This manual is intended

neither to teach the owner how to fly the aircraft, nor to publish detailed information

about the basics of strength, control and stability of weight shift controlled (WSC)

aircrafts. Training is to be accomplished by a flying instructor licensed and rated to

instruct on this type of aircraft.

This manual is the property of the aircraft owner with the identification marks listed in

Chapter 2. At every flight this document is to be held in the appropriate pocket of the

cockpit and is to be presented to the authorities if requested.

This manual contains factory recommended procedures and instructions for

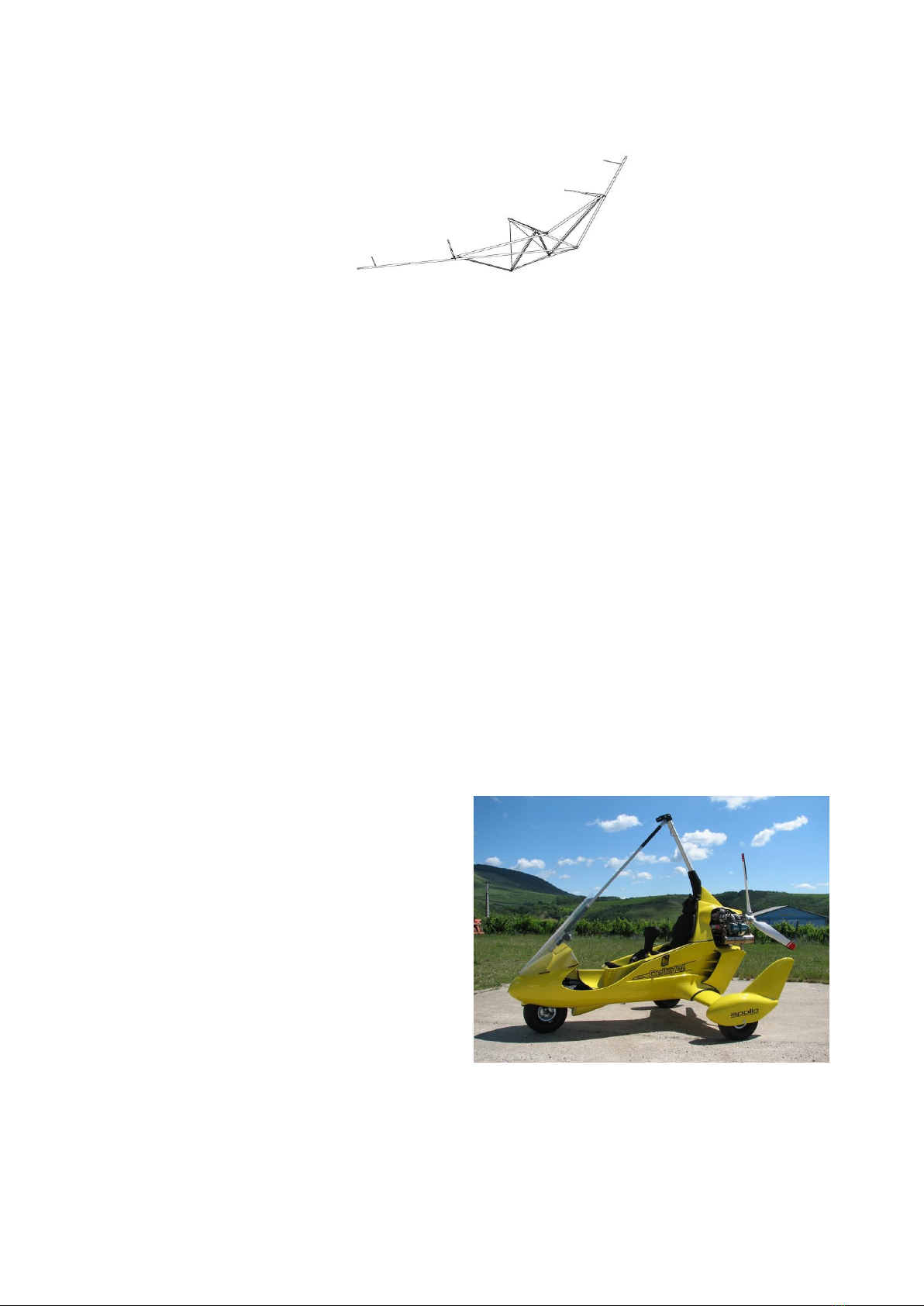

servicing, inspecting, maintaining and altering. Apollo C15 DD - Delta Jet 2 –912

WSC ultralight aircraft. The procedures described in it are to be used in addition to

the regulations of the particular governing body for each country where the aircraft is

flown. The handbooks of some Aircraft Primary Structures complete this present

basic manual, see Annexes. Legally these complementary manuals are of the same

value and of the same purpose as this present basic manual. Any problem emerges

covered neither by the rules in this Manual, nor the rules of the particular governing

body of the relevant country the prescriptions of the British Civil Aviation Regulations

Chapter „S” is to be referred to.

The information in this manual is based on the data that was available at the time of

its publication. The latest amendments to this manual will be mailed to the operators

either directly or via persons keeping constant contact with Apollo (Dealers and Type

managers, see: 5.3)together with the instructions on the actions to be done, and on

the way of annexing the amendment leafs to the aircraft basic Manual of the aircraft

owner. The AMENDMENT RECORD SHEET (see: Chapter 4) should at that time be

updated with the appropriate details and data. If any errors or omissions are found in

this Manual please, advise the factory.

It is assumed that only people with an adequate skill level will perform maintenance

on this aircraft. A sound understanding of mechanical systems, experience with the

necessary tools and procedures and knowledge of the specific flight mechanics of

WSC aircraft is required as the airworthiness of the aircraft depends on the

competence of the person performing the maintenance. If there are any doubts

regarding the required and appropriate maintenance then let Apollo Ltd or its dealer

be contacted for the correct procedures and/or servicing.

Before the beginning of operation the level of skill of the operator is to be controlled

by examiners designated either by Apollo (he may be the „dealer” if entrusted by

Apollo), or officials licensed and rated in the legal way valid in the country to state

and sign the relevant type-rating into the flight log book of the aircraft owner.

Warranty of Apollo is lost by any aerial operation, inspection, maintenance and

alteration action contradicting to any of the measures of this MANUAL. Warranty is

upheld only if measures of the MANUAL do not got offended.